Page 66

Operation

induSENSOR DTD / MSC7xxx

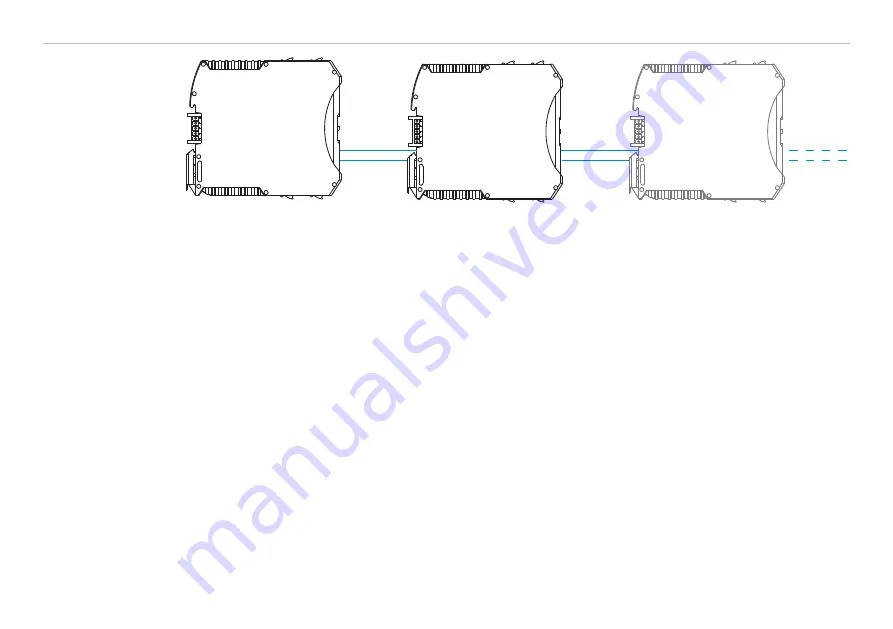

MSC7602

Channel 1: Master

Channel 2: Slave

MSC7602

Channel 1: Slave

Channel 2: Slave

Sync

signal

Sync

signal

MSC7602

Channel 1: Slave

Channel 2: Slave

Sync

signal

Fig. 66 Example of synchronization induSENSOR MSC7602

MSC7802 model

The MSC7802 offers restricted synchronization possibilities. If these are necessary in the application, please

contact Micro-Epsilon Messtechnik GmbH & Co. KG.