Design: Components and Function

2

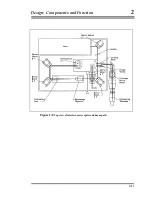

dropping and catching the test mass, as well as returning it to the top of the

chamber for the next drop. A

L

ight

E

mitting

D

iode

(LED)

, located on the

cart, directs light through an

optical glass sphere

attached to the test mass.

The sphere focuses the light onto a

linear detector

, also mounted on the cart.

This system senses the position of the cart with respect to the test mass. A

servo-motor/drive belt system

(Figure 2-2) moves the cart inside the

Dropping Chamber, using active feedback from the position sensor to

maintain the cart in a constant position relative to the test mass during free-

fall. Since there is essentially no relative motion between the test mass and

the drag-free chamber, the effects of residual air drag are eliminated.

Figure 2-4

Front view of the cart/drag-free chamber

2-4

Summary of Contents for FG5

Page 22: ...Design Components and Function 2 Figure 2 10 The Superspring 2 14 ...

Page 31: ...Design Components and Function 2 Figure 2 13 Rotation Monitor 2 23 ...

Page 32: ......

Page 42: ...How to Set Up and Run the FG5 3 3 10 ...

Page 44: ...How to Set Up and Run the FG5 3 Figure 3 2 V Post 3 12 ...

Page 53: ...How to Set Up and Run the FG5 3 1 Backup the data 2 Shut off computer power 3 21 ...

Page 87: ...Adjustment and Maintenance 4 4 29 ...

Page 91: ...Adjustment and Maintenance 4 4 33 ...

Page 104: ...Troubleshooting 5 5 2 ...

Page 117: ...Troubleshooting 5 5 15 ...

Page 131: ...Checklists and Logs Appendix D 9 3 ...

Page 140: ...Checklists and Logs Appendix D Table 9 6 Replacing Drive Belt 9 12 ...

Page 145: ...Checklists and Logs Appendix D Table 9 10 Replace Linear Bearings 9 17 ...

Page 149: ...Checklists and Logs Appendix D Table 9 13 Replace Shaft Encoder 9 21 ...