8

| POWER PACK SERVICE MANUAL

MICROMATIC.COM | 866-327-4159

INSTALLATION AND OPERATION

1. Remove packaging from the unit in the vicinity of the area where it will be installed.

2. Carefully lift the unit into the desired position.

NOTE: DO NOT PUSH OR SLIDE UNIT – Damage will be caused to the legs if the unit

is pushed into position.

PLACEMENT

• It is not recommended to install a power pack on top of a walk in cooler.

• It is not recommended to install a power pack outside.

• Always ensure a minimum clearance of 18 inches above and in front of a power pack. This allows

for proper air flow around unit.

• Ambient operating temperature range is 50-90° F for all air cooled models.

• Power pack must be wired to a ground fault circuit interrupter per UL guidelines.

INSTALLATION STEPS

(MMPP4301-EP)

(Assure tower connections are complete.)

1. Connect one of the glycol tubes to the pump inlet. Insulate any exposed tubing.

2. Connect the second glycol line to the pump outlet. Insulate any exposed tubing.

3. Carefully push the glycol bath lid to one side, allowing sufficient space to fill the bath with liquid.

4. Inspect the bath for debris.

5. Fill the glycol bath with

Micro Matic Polar Flo

®

glycol solution

(mixed 2 ½ parts water to 1 part glycol).

Fill the bath to the full level on the glycol level indicator.

6. Connect unit to the electrical outlets capable of handling the required voltage loads. This should be

carried out by suitably trained personnel and comply with all state and national electrical codes.

7. Glycol level will fall as glycol is pumped through the glycol lines. Continue to fill the bath to the fill level

on the glycol level indicator.

8. Replace top cover.

9. Inspect for any leaks.

10. Glycol temperature will fall slowly to 29° F.

NOTE: To adjust the glycol temperature, please see Adjusting Electronic Thermostat.

Summary of Contents for MMPP4301

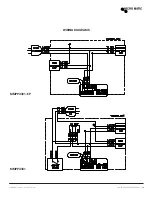

Page 15: ...MICROMATIC COM 866 327 4159 POWER PACK SERVICE MANUAL 15 WIRING DIAGRAMS MMPP4301 EP MMPP4301 ...

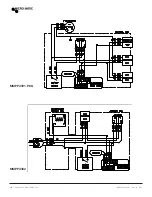

Page 16: ...16 POWER PACK SERVICE MANUAL MICROMATIC COM 866 327 4159 MMPP4301 PKG MMPP4302 ...

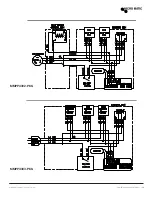

Page 17: ...MICROMATIC COM 866 327 4159 POWER PACK SERVICE MANUAL 17 MMPP4302 PKG MMPP4303 PKG ...

Page 18: ...18 POWER PACK SERVICE MANUAL MICROMATIC COM 866 327 4159 MMPP4303 PKG 3 MMPP4305 PKG ...

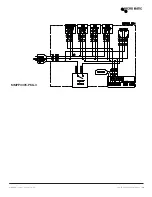

Page 19: ...MICROMATIC COM 866 327 4159 POWER PACK SERVICE MANUAL 19 MMPP4305 PKG 3 ...

Page 20: ...20 POWER PACK SERVICE MANUAL MICROMATIC COM 866 327 4159 MMPP4307 PKG MMPP4307 PKG 3 ...

Page 21: ...MICROMATIC COM 866 327 4159 POWER PACK SERVICE MANUAL 21 MMPP4307 PKG 4 ...

Page 22: ...22 POWER PACK SERVICE MANUAL MICROMATIC COM 866 327 4159 ...