Product Overview

2015 Microchip Technology Inc.

DS50002379A-page 15

1.3

WHAT IS THE MCP19111 PMBus™ PROTOCOL-ENABLED POINT-OF-LOAD

CONVERTER REFERENCE DESIGN?

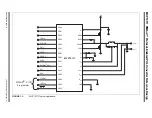

The MCP19111 PMBus™ Protocol-Enabled Point-of-Load Converter Reference

Design demonstrates how the MCP19111 device operates in a synchronous buck

topology over a wide input voltage and load range. Nearly all operational and control

system parameters are programmable by utilizing the integrated PIC microcontroller.

For precise measurements of the output current, a precision op amp

(MCP6061) and

an inductor temperature sensor (MCP9700) are provided. The output current may be

measured and calibrated using an internal or external op amp. The temperature

compensation may be performed by temperature measurement or by second order

polynomial approximation.

The PMBus Monitoring Graphical User Interface (GUI) can be used to program the

functioning parameters and to check the operational status. To simplify the connection,

a USB to PMBus converter is implemented on board, allowing a standard interface to

any Windows

®

computer.

Alternatively, the user can program the MCP19111 using self-developed firmware (see

Section 1.4.1 “The Development System’s Components”

), tailoring it to the

application.

The evaluation board contains headers for In-Circuit Serial Programming™ (ICSP™)

as well as I

2

C and mini-USB communication, pull-up and pull-down resistor pads and

test point pads on each GPIO pin, and a push button for system development. The

MCP19111 PMBus™ Protocol-Enabled Point-of-Load Converter Reference Design is

also intended to demonstrate an optimized Printed Circuit Board (PCB) layout that

minimizes parasitics, while increasing efficiency and power density.

Proper PCB layout is critical to achieve optimum MCP19111 operation, as well as

power train efficiency and noise minimization.

1.4

SYSTEM REQUIREMENTS

To operate the board, the following tools are required:

• Microsoft

®

.NET Framework 4.5 or higher

• PMBus Monitoring Graphical User Interface: This graphical user interface allows

monitoring and changing input and output parameters for any device that has an

incorporated PMBus™ protocol. For installation, operation and other system

requirements, see the

“PMBus™ Monitoring Graphical User Interface User’s

Guide”

(DS50002380).

WARNING

Any changes in the Settings tab from the Developer menu may result in system

instability and/or permanent damage of the board, and is the user’s sole responsibility

to take the necessary precautions.