SAFETY BASICS

SAFETY BASICS

6

7

SAFETY WARNING!

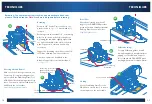

Operation of the GRR-RIPPER 3D PUSHBLOCK system

includes the use of a table saw or other tools that are not part of the GRR-RIPPER.

Micro Jig, Inc. assumes no liability for any product not sold and manufactured by

Micro Jig, Inc. The user must take all necessary precautions when operating a table

saw or other tools as recommended by their manufacturers or as required by any

prudent tool user.

You must read and agree to the safety precautions and terms listed below before

using the GRR-RIPPER 3D PUSHBLOCK system. Your assembly of the GRR-RIPPER

3D PUSHBLOCK system indicates your agreement to follow these safety precautions

and terms when using this tool.

•

All components must be inspected for

damage and securely fastened before

every use . Stop using the tool if any

damage occurs .

•

In table saw operations, the rip fence

must be securely locked parallel to the

saw blade within the usable range of the

GRR-RIPPER 3D PUSHBLOCK system .

•

In table saw operation, the face of the

Side Leg on the right must be in full

contact with the rip fence at all times

in order to create a parallel guide for

forward feeding and inward pressure

against the rip fence .

•

In table saw operations, the GRR-

RIPPER 3D PUSHBLOCK system must

be used so it is in full contact with the

rip fence at all times, and the saw blade

MUST pass through and within the

tunnel between two of the legs .

•

The GRR-RIPPER 3D PUSHBLOCK

system includes three legs with non-slip

pads . A minimum of two legs MUST be

installed during any cutting operation .

•

Use at least one leg to the right and

one leg to the left of the saw blade

whenever possible .

•

Before every cut, the user must look

through from the end of the tool after

it is in an operational position to make

sure the cutter will go through the

tunnel between the legs throughout

the entire cutting operation, without

touching any component of the tool or

other objects except the workpiece .

•

Use maximum possible coverage of the

non-slip pads on the workpiece .

•

The GRR-RIPPER 3D PUSHBLOCK

system must be used in an absolute

stable condition . When a workpiece is

narrow and is not covered by the leg on

the left (away from fence), the Balance

Support must be secured to the left leg

so the bottom surface of the Balance

Support is in full contact with the table

top to secure the steadiness of the tool

during the entire cutting operation .

•

The non-slip pads placed on the top

surface of the workpiece must be in

full contact with the workpiece . The

user should frequently inspect the

effectiveness of the non-slip pads .

Remove built up dust as necessary with

denatured alcohol .

•

The bottom of the workpiece must be

flat enough so that it does not rock on

the table top . The top of the workpiece

must be flat enough so all non-slip

surfaces are in full contact with the top

surface of the workpiece .

•

Do not use this tool if any of the

components are damaged . Contact

your dealer or the manufacturer for

replacement parts .

•

When using this tool in conjunction with

any other tool, first read and follow all

instructions and safety information in

the owner’s manual for that tool .

•

When not in use, store this product on a

flat and clean surface .

•

Always wear safety glasses and hearing

protection . Follow all normal shop

safety practices .

•

Use saw blades that are designed for

the intended cutting operation .

•

When using only one GRR-RIPPER, the

user must have both hands on this tool

- one gripping the handle and the other

on top of the main body .

•

The machine tabletop used in

conjunction with this tool must be

flat and free from obstructions other

than the required fence and one

cutting element . The tabletop must be

reasonably level and below the waistline

of the user .