525 Berne St

Berne, IN 46711

1-260-589-2136 x3211

customerservice@micromaticllc.com

Page

8

of

10

26-18-1006 rev.-

Model: LONG ARM

TIPPER MOUNTING OPTIONS

The standard tipper base mounting plate is equipped with one mounting pattern:

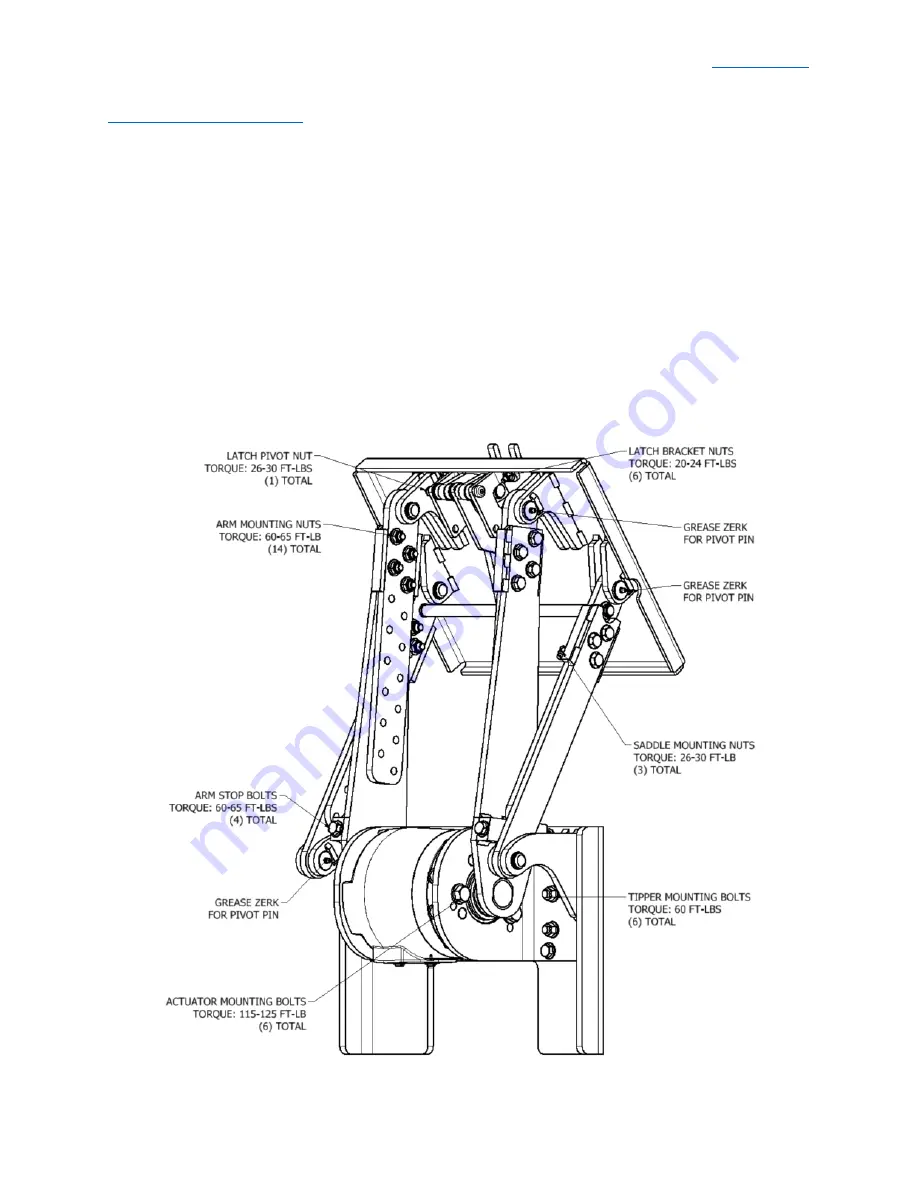

MAINTENANCE

Lubrication

➢

Pivot joints are equipped with six (6) easy access grease zerk fittings.

➢

Main pivot joints should be greased monthly to flush contaminates from pivot joint.

Inspection Prior to Each Use

➢

Fasteners should be inspected to ensure all are in place and tight

– See Torques below.

➢

Stop bolts serve a functional purpose to limit the rotation of the actuator. Make sure they

are in place and do NOT remove them.

➢

Inspect all welds for cracks and repair or replace as necessary.

➢

Hydraulic oil and oil filter on the waste truck should be checked periodically and changed

according to the manufacturer-recommended intervals.