A

LTERNATING

V

ACUUM

B

ACKFILL

P

REPARATION

Alternating vacuum-backfill sample preparation utilizes a combination of vacuum and gas

backfilling techniques to remove contaminants and prepare samples for analysis. The VacPrep is

designed for low-pressure backfilling only.

Do not exceed 5 psi regulator pressure when backfilling sample tubes. If the gas pres-

sure is greater than the recommended maximum of 5 psig (35 kPag), the sample tube

could be ejected from the fitting or broken.

Some fine-powdered samples such as controlled pore glass, fluid-cracking catalysts,

and carbon may be difficult to prepare by vacuum preparation. Such materials tend to

fluidize and float up the sample tube toward the vacuum source. Micromeritics

recommends that such samples be first prepared by flowing gas preparation and, if

necessary, then be subjected to vacuum preparation.

If sample has been accidentally sucked into the instrument, see

Vacuum Fittings on page 5 - 13

.

1. Turn all VAC/GAS control knobs to the OFF position. Ensure that the vacuum pump is

powered ON and that gas is being supplied to the degasser.

2. Attach a vacuum fitting to each piece of flexible tubing at a degas station to be used for

sample preparation.

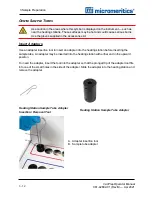

1/2 in. or 12 mm O-ring and

ferrule (for 1/2 in. or 12 mm

sample tubes)

3/8 in. or 9 mm O-ring and

ferrule (for 3/8 in. or 9 mm

sample tubes)

3. Power on the VacPrep.

4. Set the temperature controller using the temperature set point.

5. Remove the stopper from the sample tube and attach the sample tube to the vacuum fitting.

a. Loosen the knurled retaining nut.

b. Insert the sample tube fully into the fitting. There will be a slight resistance as the tube

passes through the O-ring.

Alternating Vacuum Backfill Preparation

VacPrep Operator Manual

061-42802-01 (Rev B) — Apr 2021

4 - 5