7

www.micronfilter.it

ENGLI

SH

4.0 INSTALLATION

THE CLEANER MUST BE INSTALLED BY SPECIALISED PERSONNEL

The place where the cleaner is to be installed must be spacious enough to make it possible to

access the machine comfortably and safely, for all routine or extraordinary maintenance

operations.

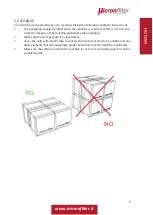

4.1 POSITIONING THE CLEANER

Make sure the place where the cleaner is to be installed is perfectly flat. Lift the cleaner using

the hooks and place it in its seat, in the tank.

4.2 CONNECTION TO THE WATER MAINS

Use a hose connection (not included in the standard supply) to

connect a flexible tube to the entrance of the cleaner (see figure on

the side). Alternatively, this connection can be made using

hydraulic components (tubes, elbows etc), suitably sized.

4.3 CONNECTION TO THE POWER MAINS

ALL ELECTRIC CONNECTIONS FOR THE CLEANER MUST ONLY BE CARRIED

OUT BY SKILLED ELECTRICIANS, WITH THE POWER CUT OFF FROM THE

EQUIPMENT.

PRIOR TO MAKING THE ELECTRIC CONNECTIONS FOR THE CLEANER, CHECK

THE WIRING DIAGRAM ATTACHED TO THIS MANUAL.

Make sure the connection voltage is equal to the voltage of the power grid (check the plate

attached to the terminal of the motor reducer).

Check the information on the plate on the cleaner (verify the electric characteristics in the

table below) in order to choose the proper connection materials (sections, cables etc).

Cleaner

Kalamit

75

Kalamit

150

Kalamit

250

Kalamit

350

Kalamit

500

Voltage

230/400

V

230/400V

230/400V

230/400V

230/400V

Frequency

50 HZ

50 HZ

50 HZ

50 HZ

50 HZ

Total rated power

0.12 kW

0.12kW

0.12kW

0.12kW

0.12kW

Current at full power

0.62A

0.62A

0.62A

0.62A

0.62A

Motor reducer

Double

Double

Double

Double

Double

Number of poles

6

6

6

6

6

Reduction ratio

1/600

1/600

1/600

1/600

1/600