12 |

U s e r ´ s a n d i n s t a l l a t i o n m a n u a l

D R Y S I R E N

P a g e 1 2 o f 6 8

V e r s i o n : 0 1 / 2 0 1 8

SW

IM

M

IN

G

P

O

O

L

D

EH

U

M

ID

IF

IE

R

DR

Y

S

IR

E

N

33 - Cutter – tube

1/2, 3/8

1x

34 - Tube Bender – tube

1/2, 3/8

35 – Saw for iron

1x

6.

INSTALLATION

–

CEILING UNIT

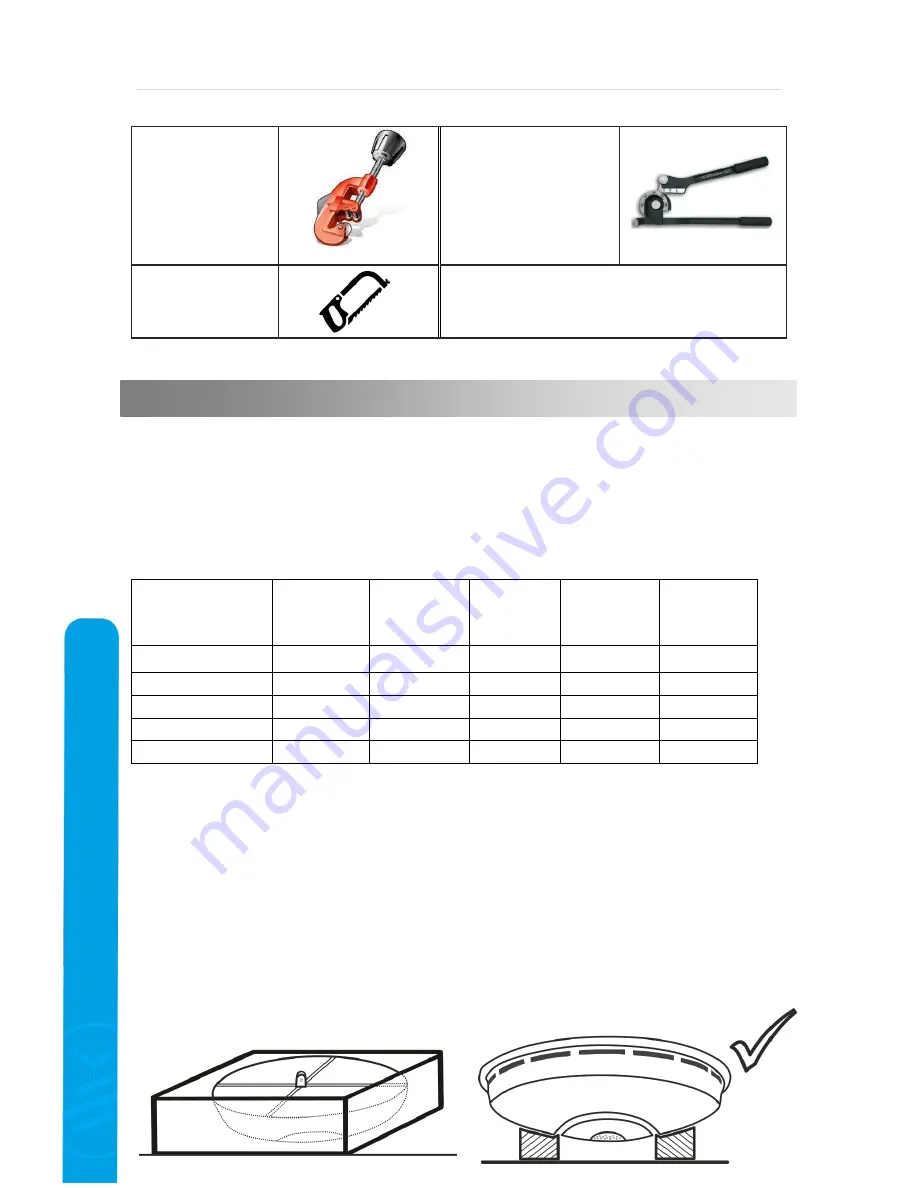

Ceiling unit is designed for an installation at the ceiling or at lower ceiling. Typically the ceiling unit is

fixed into the concreted structure of the upper floor or wooden roof. Please make sure that the

material into which the ceiling unit is to be fixed is suitable for such installation. Manufacturer is not

responsible for damages or losses caused by an incorrect installation or inappropriate concrete or

wood type. Ideally it should be installed above the evaporation source. It should be installed on easy

accessible spot to allow maintenance and service.

Please view following

concrete types and strengths

.

Pressure class

f

ck,cyl

(MPa)

f

ck,cube

(MPa)

Appropriate Threaded

bar TR8 L1

drill depth

Anchor

for

lifting

mechanism

C8/10

8

10

No

N/A

N/A

C12/15

12

15

No

N/A

N/A

C16/20

16

20

Yes

80mm

60mm

C20/25

20

25

Yes

60mm

60mm

C25/30 and more

25 and more 30 and more

Yes

40mm

60mm

Concrete marking with additional request for seepage resistance: STN EN 206-1 –C25/30-XF2,XC2

(SK) – Cl 0,4 – Dmax 16 – S3, seepage 50mm according to STN EN 12390-8.

6.1

BASIC MANIPULATION

The unit is designed to be located on the ceiling. We, at Microwell, had to ensure a perfect balance

between weight and long-term durability with focus on reliability of the product. It is thus necessary

to mind below manipulation information and comply with them. Non-compliance may lead to

product damage, malfunction or failure. Manufacturer is not resosonsible for incorrect manipulation

or for manipulation not compliant to this User’s manual.

Ceiling unit is delivered in a box with polystyrene support from the bottom at sides.