V Electrical

The length of horizontal uninsulated Vent Connector between chimney and a single gas

utilization equipment shall not exceed 75% of the height of the chimney above the

connector, or 100% if the Vent Connector is insulated.

The Vent Connector shall be installed so as to avoid turns or other construction features

which create excessive resistance to flow of vent gas. It shall be installed without any dips

or sags and shall slope upward at least 1/4" per foot.

A manually operated damper shall

not

be placed in the Vent Connector or chimney of

any gas utilization equipment.

The Vent Connector shall be firmly attached to draft hood outlets and flue collars. Joints

between sections of connector piping shall be fastened by sheet-metal screws or other

approved means. The Vent Connector shall be supported for the design and weight of the

material employed to maintain clearance and prevent physical damage and separation of

joints.

A draft hood or a barometric draft regulator shall be installed in the same room or

enclosure as the equipment in such a manner as to prevent any difference in the pressure

between the hood or regulator and the combustion air

supply. In no case shall the relief opening of the draft hood

or barometric draft regulator be located at a point lower than

the top of the highest flue passage in the equipment.

Gas utilization equipment requiring controlled draft may

be equipped with a listed double acting barometric draft

regulator, installed and adjusted in accordance with the

manufacturer’s instructions,

if approved by local codes

.

A device which will automatically shut off gas to the

burner in the event of sustained backdraft is required. It

shall be of the listed manual reset type and installed and

adjusted by a qualified service technician in accordance

with the manufacturer’s instructions.

______________________________________________________

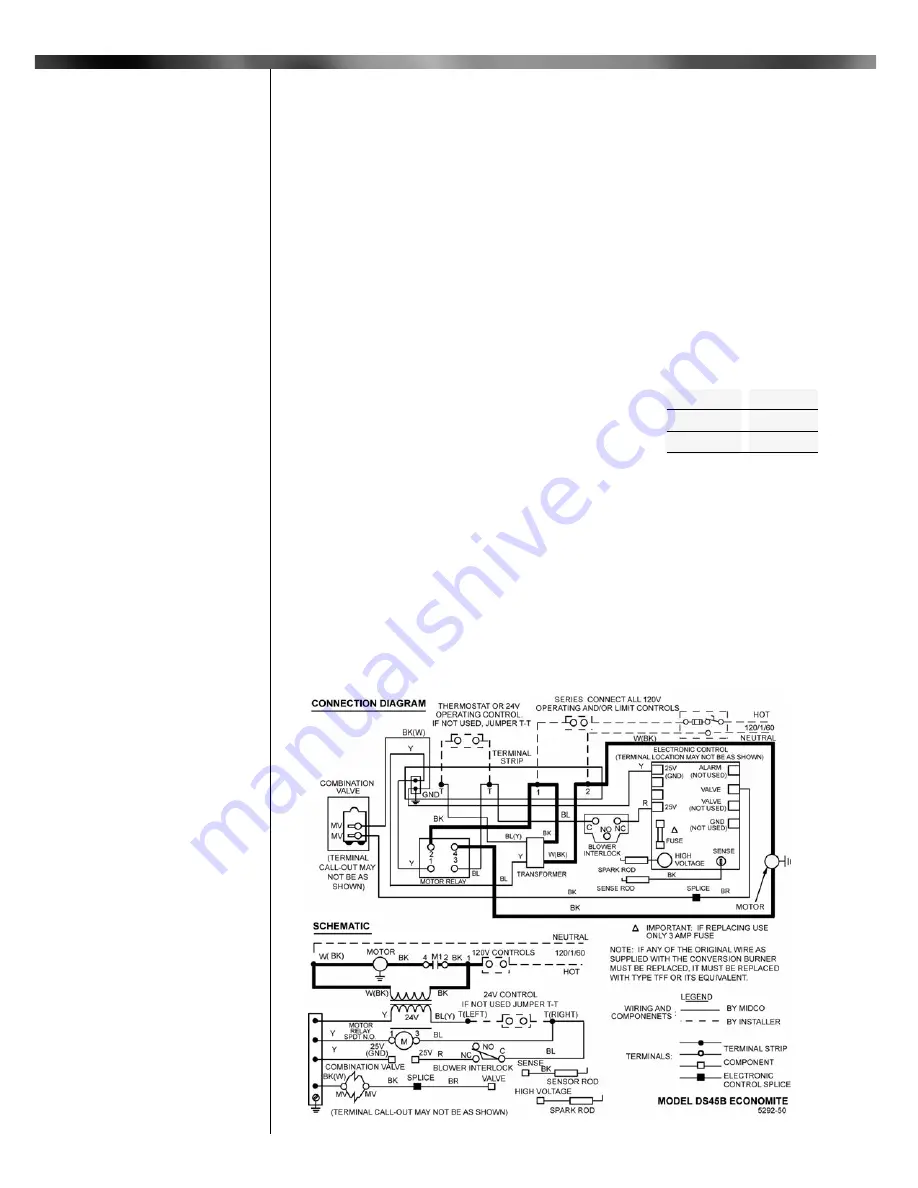

Installation wiring and grounding of the burner must conform to local codes, or, in their

absence in the United States to

National Electric Code, ANSI/NFPA No. 70

- latest edition;

in Canada, to

Canadian Electrical Code Part 1, CSA Standard C22.1

.

Use copper wire not less than 14 gage for line voltage wiring. Be sure to hook up to

permanently live circuit. Provide a fused on-off disconnect switch carrying a minimum 3

amp fuse.

4

Part 1 Installation

Part 1

Installation

Continued

IV Chimney, Vent

Connector*, and

Draft Control

Continued

250 MBH

320 MBH

400 MBH

7”

8”

9”

Maximum

Input

Flue Pipe

Diameter

Table 1:

Recommended

Vent Connector Sizes

Figure 4:

Wiring Diagram