■

■

The Vent Connector shall be as short as possible.

The entire length shall be readily accessible for

inspection, cleaning and replacement.

■

■

The length of horizontal uninsulated Vent Connector

between chimney and a single gas utilization equipment

shall not exceed 75% of the height of the chimney above

the connector, or 100% if the Vent Connector is

insulated.

■

■

The Vent Connector shall be installed so as to avoid

turns or other construction features which create

excessive resistance to flow of vent gas. It shall be

installed without any dips or sags and shall slope upward

at least 1/4" per foot.

■

■

A manually operated damper shall not be placed in the

Vent Connector or chimney of any gas utilization

equipment.

■

■

The Vent Connector shall be firmly attached to draft

hood outlets and flue collars. Joints between sections of

connector piping shall be fastened by sheet-metal

screws or other approved means. The Vent Connector

shall be supported for the design and weight of the

material employed to maintain clearance and prevent

physical damage and separation of joints.

■

■

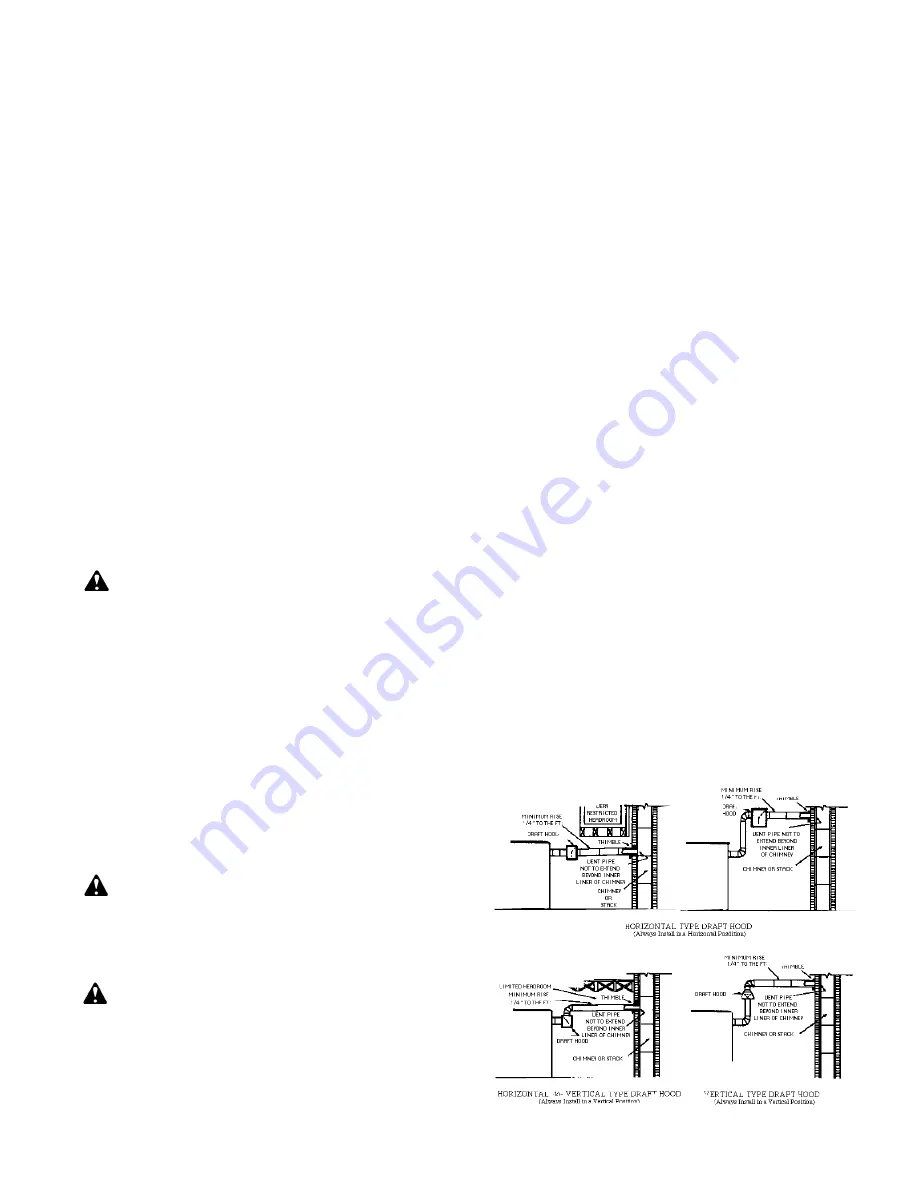

A draft hood or a barometric draft regulator shall be

installed in the same room or enclosure as the

equipment in such a manner as to prevent any difference

in the pressure between the hood or regulator and the

combustion air supply (see Figures 3 and 4). In no case

shall the relief opening of the draft hood or barometric

draft regulator be located at a point lower than the top of

the highest flue passage in the equipment.

■

■

Gas utilization equipment requiring controlled draft

may be equipped with a listed double acting barometric

draft regulator, if a approved by local codes.

■

■

A device which will automatically shut off gas to the

burner in the event of sustained backdraft is required. It

must be of the listed manual reset type and installed and

adjusted by a qualified service technician in accordance

with the manufacturer's instructions.

■

■

Refer to the gas utilization equipment manufacturer for

recommended vent connection requirements.

FIGURE 3

Recommended Locations for Draft Hoods

III COMBUSTION CHAMBER

A combustion chamber liner is normally required to

protect non-heat transfer surfaces and to provide a

radiant bed for rapid heat transfer to the primary surfaces

of the heat exchanger. In most cases the existing

combustion chamber liner formerly used for oil burner

can be used, if in good condition.

■

■

In the case of wet base boilers, where the entire firing

chamber is comprised of heat exchange surfaces and no

chamber liner was provided for oil firing, a liner is usually

not required for the ECONOMITE. However, a liner or

target wall may be necessary if the firing chamber is

unusually short, in order to avoid flame contact on the

heat exchanger walls or flueways.

■

■

If a built up chamber liner is required, use 2,300°F

minimum insulating material.

■

■

The burner tube must be sealed air tight into the

combustion chamber opening with refractory material as

shown by Figures 1 and 2.

NOTE: In no case should the burner tube be allowed to

extend into the chamber proper; it must be set flush to 1"

short of the inside surface because high combustion

chamber temperatures will cause premature pilot,

electrode, burner tube and sleeve deterioration.

■

■

Special heat resistant alloy extension tubes and

instructions are available for those applications where

the burner tube is too short to reach the combustion

chamber (such as old-fashioned gravity warm air furnace

installations.)

WARNING: BURNER CABINET MUST BE

MOUNTED IN ORIENTATION SHOWN IN FIGURES 1

AND 2. ANY OTHER MOUNTINGS MAY CAUSE A

DANGEROUS CONDITION, AND WILL VOID BURNER

WARRANTY AND AGENCY APPROVALS. NON-

STANDARD ARRANGEMENTS MAY BE AVAILABLE

FOR SOME MODELS-CONSULT FACTORY FOR

DETAILS REQUIRED.

■

■

Before permanently setting the burner in place, check

that the burner ports and pilot are free of foreign

materials, and also that the electrodes have not been

damaged or displaced. See Figure 7.

IV CHIMNEY, VENT CONNECTOR,

AND DRAFT CONTROL

WARNING: The chimney shall be inspected for

unsafe conditions such as deteriorated masonry and

excessive soot or other blockage or potential

blockage. Installation must conform with local codes

or in the absence of local codes with ANSI Z21.8b-

1993 and NFPA, ANSI Z223.1-1992.

WARNING: THE VENT CONNECTOR SHALL NOT

BE CONNECTED TO A CHIMNEY ALREADY

VENTING SOLID FUEL BURNING EQUIPMENT, AN

INCINERATOR OR AN OPEN FIREPLACE.

■

■

The Vent Connector shall be made of non-

combustible, corrosion resistant material capable of with-

standing the vent gas temperature produced by the gas

utilization equipment and of sufficient thickness to with-

stand physical damage.

-3-