Page 6

GROUNDING AND BONDING

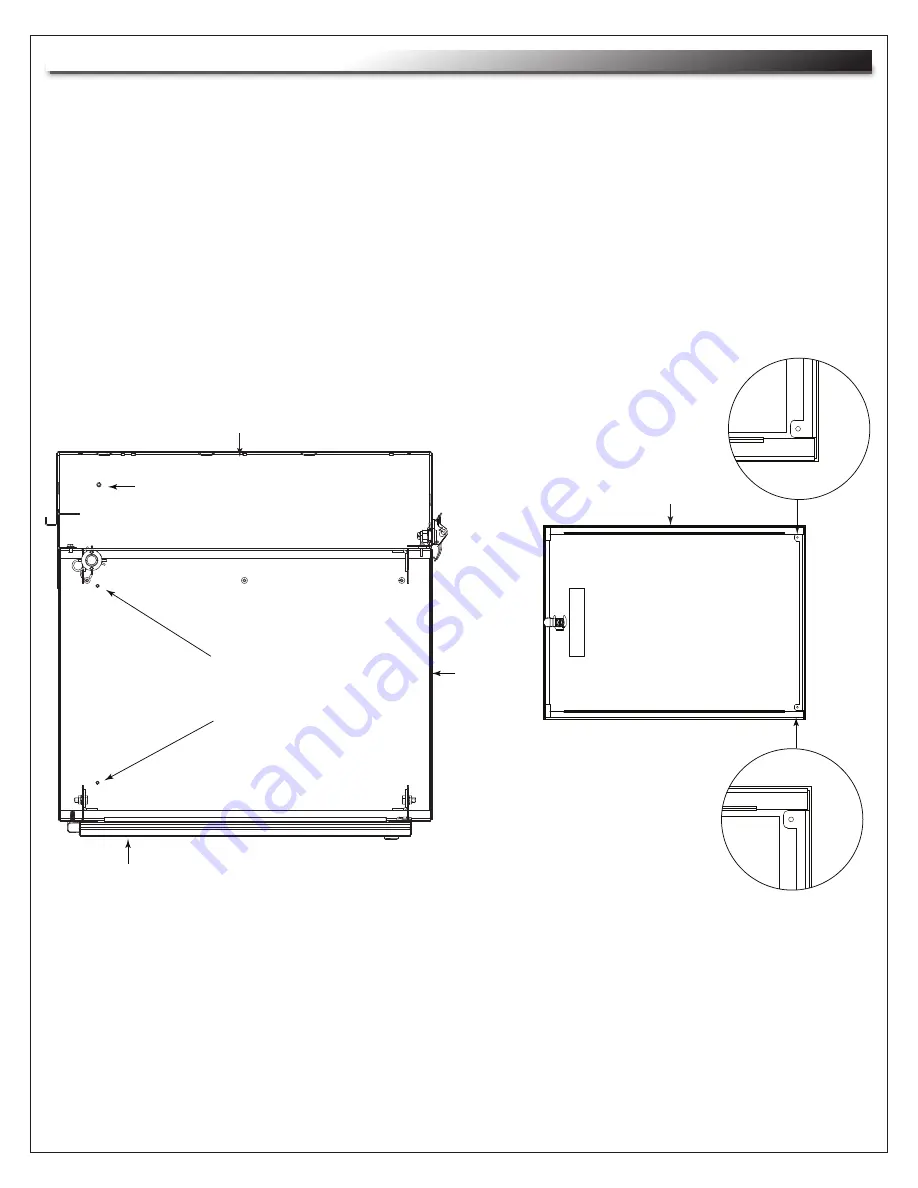

Center

Section

Backpan

Door

Center Section Bonding Studs

10-32 (2 Upper and 2 Lower)

Backpan PET Stud

Door Bonding Points

(1 Upper and 1 Lower)

1) Attach

backpan bonding wire

from 1/4”-20 backpan protective earth terminal (PET) to nearest

center section bonding stud (10-32) using hardware provided.

(FIGURE G)

NOTE:

The main protective earth ground needs to be the first terminal placed on the PET and this

terminal needs to be secured on its own with a nut. The bonding wire for the center section can

be added to the PET after securing the nut for the main ground.

(FIGURE G)

2)

FOR OPTIONAL DOOR:

Attach

door bonding wire

(with male or female disconnect end) to door

bonding point with self-tapping screw (included).

(FIGURE G)

3) Attach remaining door bonding wire to nearestcenter section bonding stud (10-32) using hardware

provided.

(FIGURE G)

4) Connect male and female ends of door bonding wire set.

FIGURE G

OVERHEAD VIEW

FRONT VIEW

Door