6

ENGLISH

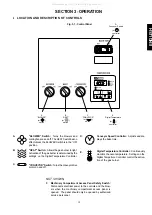

I. INSTALLATION KIT

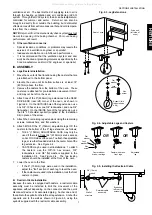

Fig. 2-1 - Installation Kit

18"

458mm

18"

458mm

12"

305mm

3"

76mm

2"/51mm

minimum

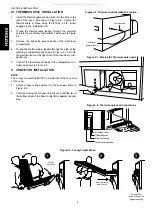

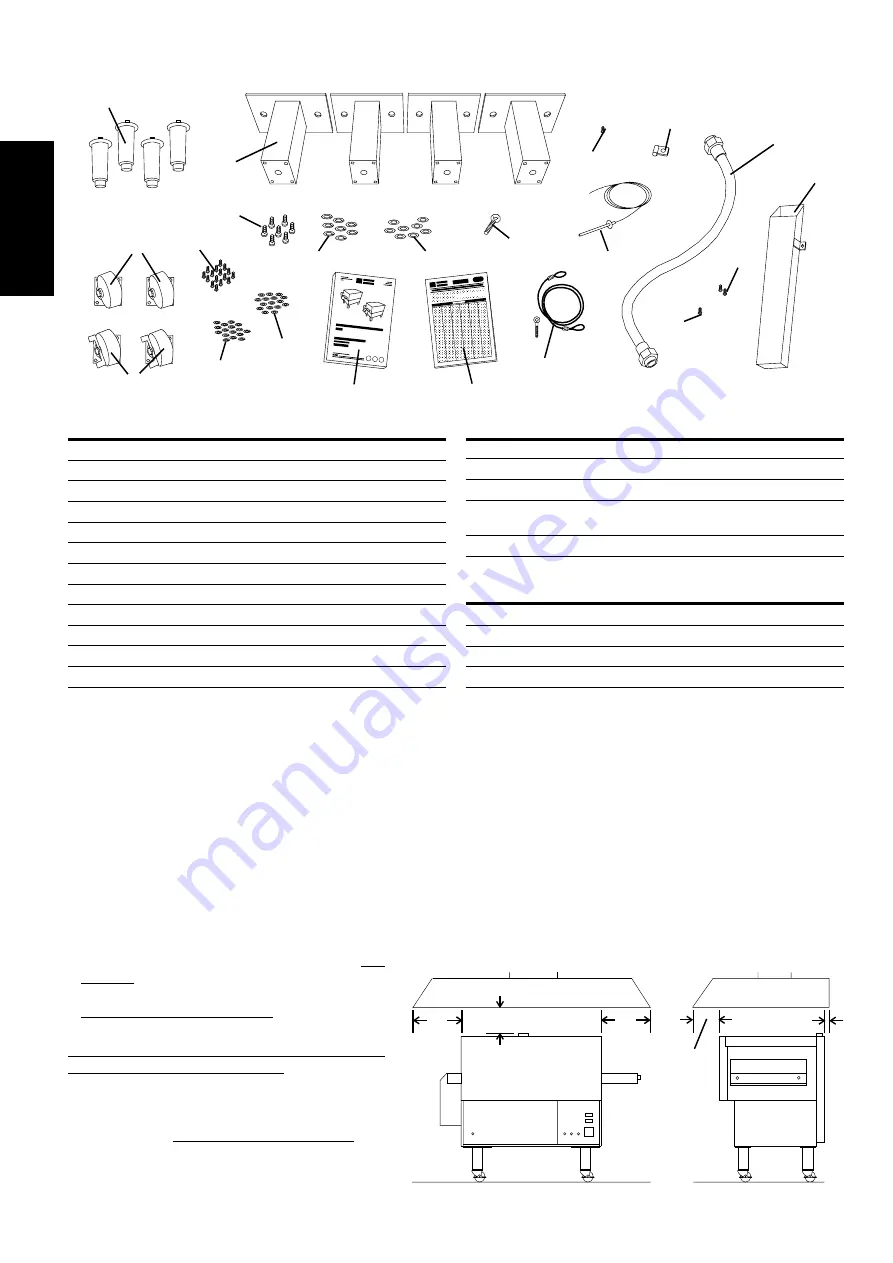

II. VENTILATION SYSTEM

IMPORTANT

Where national or local codes require the installation of fire

suppression equipment or other supplementary equipment,

DO NOT mount the equipment directly to the oven.

MOUNTING SUCH EQUIPMENT ON THE OVEN MAY:

VOID AGENCY CERTIFICATIONS

RESTRICT SERVICE ACCESS

LEAD TO INCREASED SERVICE EXPENSES FOR THE

OWNER

A. Requirements

CAUTION

A mechanically driven ventilation system is RE-

QUIRED for gas oven installations.

A mechanically driven ventilation system is

STRONGLY RECOMMENDED for electric oven

installations.

PROPER VENTILATION OF THE OVEN IS THE RE-

SPONSIBILITY OF THE OWNER.

B. Recommendations

NOTE THAT THE HOOD DIMENSIONS SHOWN IN

FIGURE 2-2 ARE RECOMMENDATIONS ONLY. LO-

CAL AND NATIONAL CODES MUST BE FOLLOWED

WHEN INSTALLING THE VENTILATION SYSTEM.

Fig. 2-2 - Ventilation System

1

2

3

7

14

15

18

19

4

5

6

16

17

12

13

8

9

10

Item

Description

Part Number Qty.

1

Legs, adjustable

22450-0028

4

2

Caster (Rear), Swivel

22290-0010

2

3

Caster (Front), Swivel, with brake

22290-0009

2

4

Screw, hex, 3/8-16 x 1"

220373

16

5

Lockwasher, 3/8"

21422-0001

16

6

Flat washer, 3/8"

21416-0001

16

7

Leg, 9" (229mm)

34684

4

8

Screw, hex, 3/4-10 x 2"

21321-0016

7

9

Lockwasher, 3/4"

21421-0003

8

10

Flat washer, 3/4"

21411-0019

8

11

Shoulder eyebolt, 3/4"-10 x 2"

42440

1

12

Restraint Cable Assembly

22450-0228

1

A.Installation kit components

13

Thermocouple

33812-1

1

14

Cable Clamp

27276-0001

1

15

Screw, #10-32 x 3/8"

21256-0008

1

16

Model PS314SBI Owner's Operating

42447

1

and Installation Manual

17

Authorized Service Agency Listing

1002040

1

B. Additional installation kit components for gas ovens

18

Gas hose, flexible

22361-0001

1

19

Flue vent, 14" (356mm)

30773

1

20

Screw, hex, #2PT 10-16 x 3/4" HWH

21292-0001

2

21

Screw, #10-32 x 3/8"

21256-0008

1

ANY APPLICABLE LOCAL AND NATIONAL CODES SUPER-

SEDE THE RECOMMENDATIONS SHOWN IN THIS MANUAL.

The rate of air flow exhausted through the ventilation system

may vary depending on the oven configuration and hood design.

Consult the hood manufacturer or ventilation engineer for these

specifications.

To avoid a negative pressure condition in the kitchen area,

return air must be brought back to replenish the air that was

exhausted. A negative pressure in the kitchen can cause heat-

related problems to the oven components as if there were no

SECTION 2 - INSTALLATION

11

Item

Description

Part Number Qty.

20

21

All manuals and user guides at all-guides.com

all-guides.com