14

SECTION 2

INSTALLATION

III. ELECTRICAL CONNECTION

INFORMATION FOR PS528-SERIES

OVENS.

WARNING

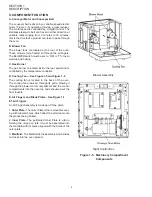

Authorized supplier personnel normally accom-

plish the connections for the ventilation system,

electric and gas supplies, as arranged by the

customer. Following these connections, the

factory-authorized installer can perform the initial

startup of the oven.

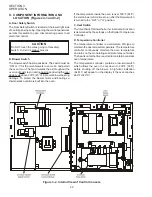

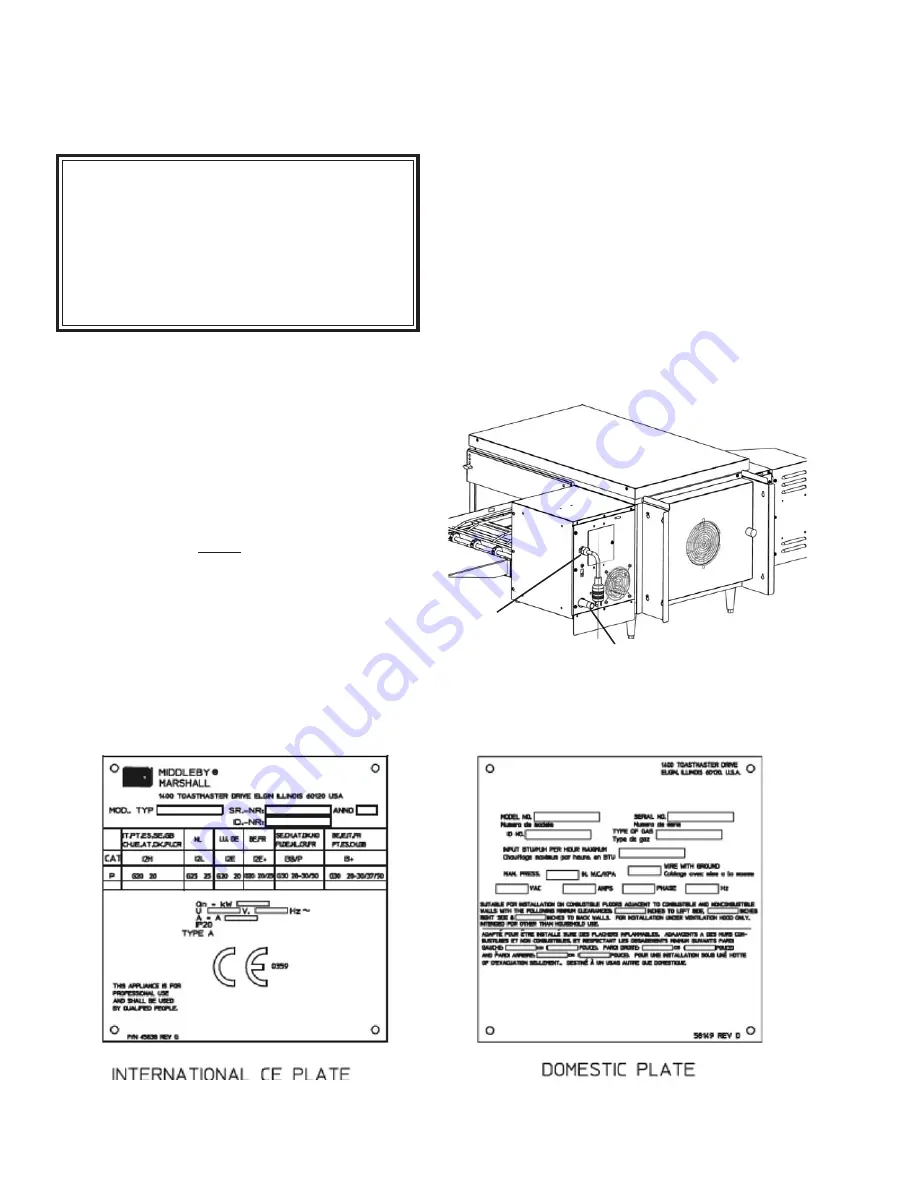

Check the oven data plate (Figure 2-10) before making

any electric supply connections. Electric supply connec-

tions must agree with data on the oven data plate.

NOTE: The electric supply installation must satisfy the

requirements of the appropriate statutory authority, such

as the National Electrical Code (NEC), ANSI/NFPA70,

(U.S.A.); the Canadian Electrical Code, CSA C22.2;

the Australian Code AG601; or other applicable regula-

tions.

A fused disconnect switch or a main circuit breaker

(customer furnished) MUST be installed in the electric

supply line for each oven; it is recommended that this

switch/ circuit breaker have lockout/tagout capability. The

electric supply connection must meet all national and local

electrical code requirements. Copper is the recommended

material for the electrical supply conductors.

IV. ELECTRIC SUPPLY FOR GAS HEATED

OVENS

Power requirements for gas heated ovens are 208 -

240VAC, 1-phase, 3-wire (2 ‘hot’, 1 ground). Electrical

connection is made through a cord and plug. Using

flexible cable(s) for the electrical power supply conductors

requires a 2

″

(51mm) strain-relief fitting (not furnished)

to enable safe access to the terminal block from which

oven power is distributed.

The supply conductors must be of the size and material

(copper) recommended to provide the current required;

(refer to the data plate for the ampere specifications).

The electric current rating for each conductor supplying

a PS528-Series Oven is 1.5A.

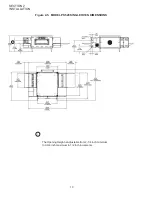

Figure 2-11. Junction Connection Box

Figure 2-10. Typical Electric Oven Data Plate

ELECTRICAL

INLET

GAS INLET