Service Manual_2018-V2.0

23

8.4Air duct components refrigerating chamber and fan motor

Air duct components in freezing chamber

1

)

Remove two screws from the refrigerating air duct

with a cross screwdriver;

2

)

Pull all connector terminals out of the refrigerating

air duct to remove its components;

Fan motor of air duct

None

Electric damper

None

8.5Air duct components in freezing chamber and fan motor

(None)

Air duct components in freezing chamber

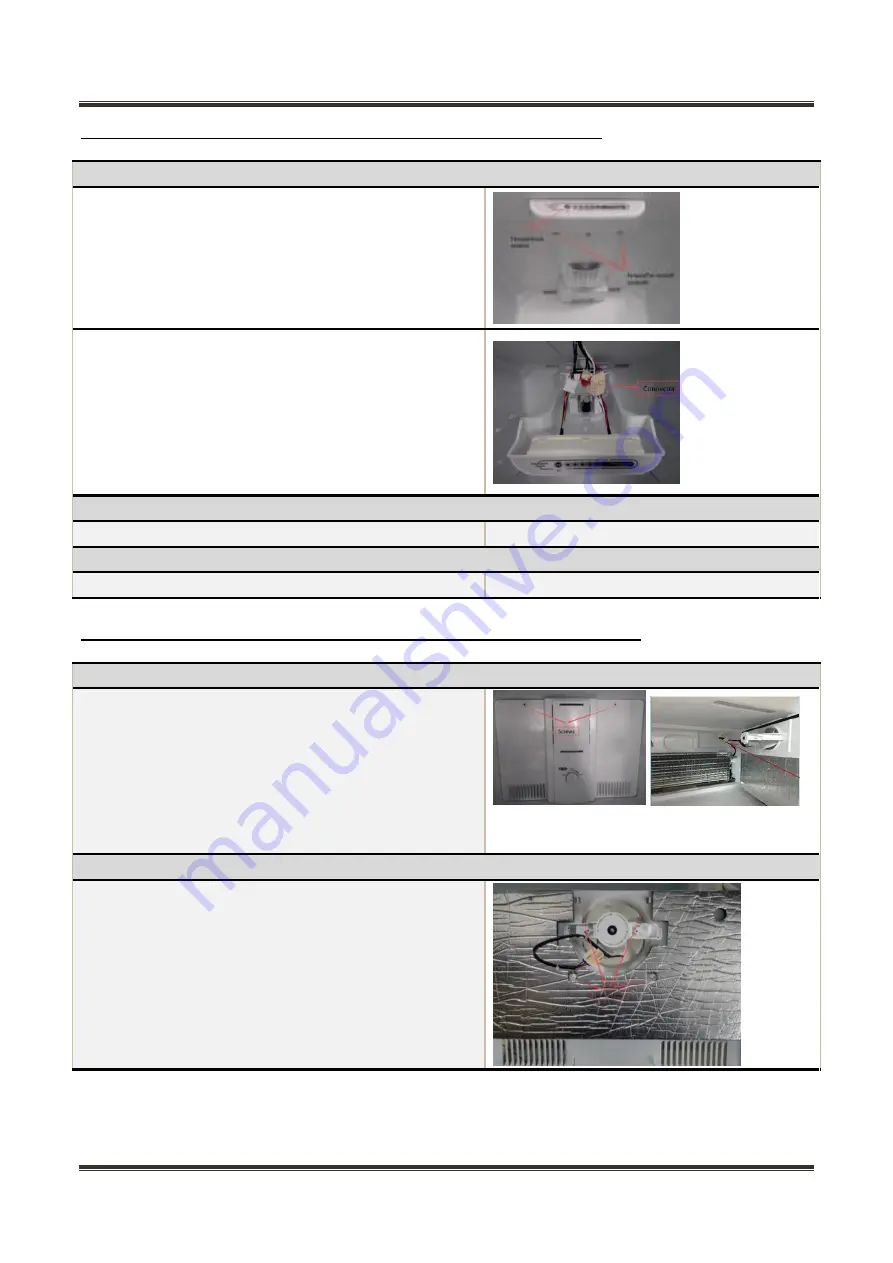

All accessories in the freezing chamber should be

dismantled before removing the air duct components.

1

)

Remove 2 screws on the cover plate of the freezing air

duct using a cross screwdriver;

2

)

Pull out it from the bottom of freezer chamber air

duct.3

)

Pull out the connector terminal of the fan motor;

4) The reverse operation for assembly

Fan motor of air duct

1

)

Disassemble buckles at the back of the freezing air

duct and remove 4 front cover plates;

Summary of Contents for 22031020003641

Page 5: ...Service Manual_2018 V2 0 5 1 Significant update notes None...

Page 18: ...Service Manual_2018 V2 0 18 6 5Main control board schematic diagram...

Page 20: ...Service Manual_2018 V2 0 20 7 3 Circulating route of cooling air...

Page 38: ...Service Manual_2018 V2 0 38 12 Troubleshooting Method 12 1 No cooling Air cooling Electronic...

Page 39: ...Service Manual_2018 V2 0 39 12 2 No working of compressor 12 3 Inside frosting no defrosting...

Page 40: ...Service Manual_2018 V2 0 40 12 4 Inside frosting no defrosting Maintenance guidelines...

Page 41: ...Service Manual_2018 V2 0 41 12 5 Light is not on 12 6 Fan failure...

Page 42: ...Service Manual_2018 V2 0 42 12 7 Defective defrost circuit 12 8 Noise...

Page 43: ...Service Manual_2018 V2 0 43 12 9 Air duct not operated electronically None...

Page 44: ...Service Manual_2018 V2 0 44 13 Figures and details of repair parts See this section in the TSP...