Service Manual_2018-V2.0

28

10

)

Use Pipe cutter cut off the condenser tube

❽

, then

Shear off capillary

❾

by the capillary tube scissors.

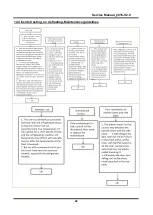

11

)

Replace the compressorand welding the compressor

pipeline.-

❿

Welding the process pipeline.-

⓫

Welding the

low-pressure muffler.-

⓬

Welding the high-pressure

exhaust pipe.

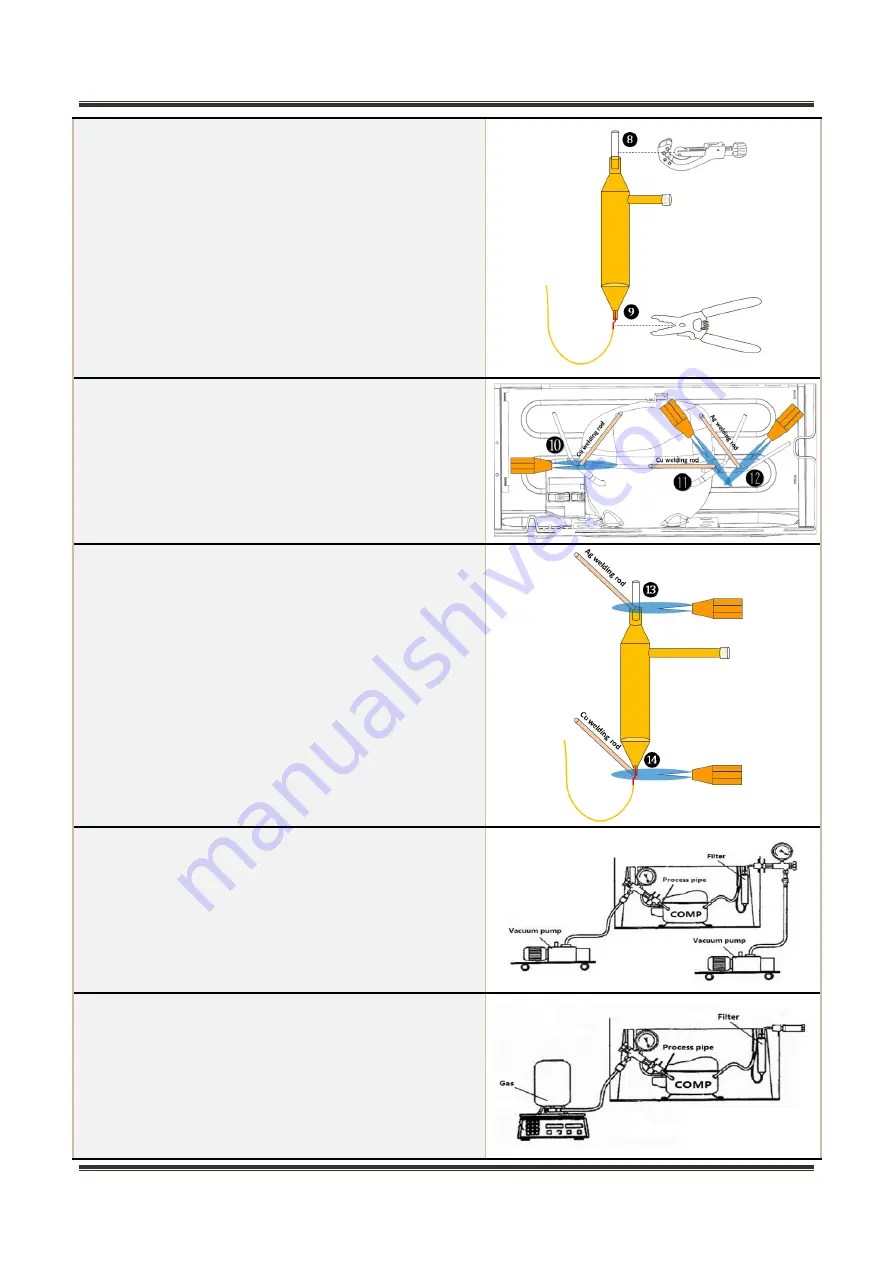

12

)

Replace the filter, Cu-Fe tubes welding

⓭

used Ag

welding rod, Cu-Cu tubes welding

⓮

used Cu welding

rod.

13

)

Vacuum system,The degree of vacuum below 6Pa.

14

)

Perfusion refrigerant.

Summary of Contents for 22031020003641

Page 5: ...Service Manual_2018 V2 0 5 1 Significant update notes None...

Page 18: ...Service Manual_2018 V2 0 18 6 5Main control board schematic diagram...

Page 20: ...Service Manual_2018 V2 0 20 7 3 Circulating route of cooling air...

Page 38: ...Service Manual_2018 V2 0 38 12 Troubleshooting Method 12 1 No cooling Air cooling Electronic...

Page 39: ...Service Manual_2018 V2 0 39 12 2 No working of compressor 12 3 Inside frosting no defrosting...

Page 40: ...Service Manual_2018 V2 0 40 12 4 Inside frosting no defrosting Maintenance guidelines...

Page 41: ...Service Manual_2018 V2 0 41 12 5 Light is not on 12 6 Fan failure...

Page 42: ...Service Manual_2018 V2 0 42 12 7 Defective defrost circuit 12 8 Noise...

Page 43: ...Service Manual_2018 V2 0 43 12 9 Air duct not operated electronically None...

Page 44: ...Service Manual_2018 V2 0 44 13 Figures and details of repair parts See this section in the TSP...