MCAC-ATSM-2013-11 Aqua Tempo Power Series (with LAK) air cooled scroll chiller unit (50Hz)

139

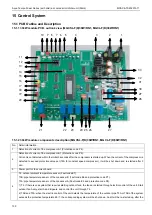

temperature.

Adjustment range of constant speed capability: ON and OFF. Adjustment range of constant speed capability: ON and OFF.

7

Inlet water temperature sensor (Fault code EF).

8

Total outlet water temperature sensor (Fault code E3).

Only the main unit is valid, and the subordinate units are invalid.

Under refrigerating mode and heating mode, conduct adjustment according to the magnitude of total outlet water

temperature. Adjustment range: Load, stabilize, unload, Emergency Stop.

9

Remote mode control port(ON/OFF signal, effect on NO.0 unit).

1.Dial the code S7 in the main control board to the

“ON” position and enter to the remote control mode (The wired controller is

invalid).

2.First, the ON/OFF port is closed, second, if this port is closed, the unit enters the heating mode, else, the unit enters the

cooling mode.

10

Remote mode control port(ON/OFF signal, effect on NO.0 unit).

1.Dial the code S7 in the main control board to the

”ON” position and enter to the remote control mode (The wired controller is

invalid)

2. If the port is closed, the unit is turned on, else, the unit is turned off.

11

Electronic expansion valve of the system B.

12

Numerical code tube.

1) In case of stand-by, the address of the module is displayed.

2) In case of normal operation, 10. Is displayed (10 is followed by dot).

3) In case of fault or protection, fault code or protection code is displayed.

13

Electronic expansion valve of the system A.

Electronic expansion valve is used to control refrigerant flow under different operating modes and different loads.

14

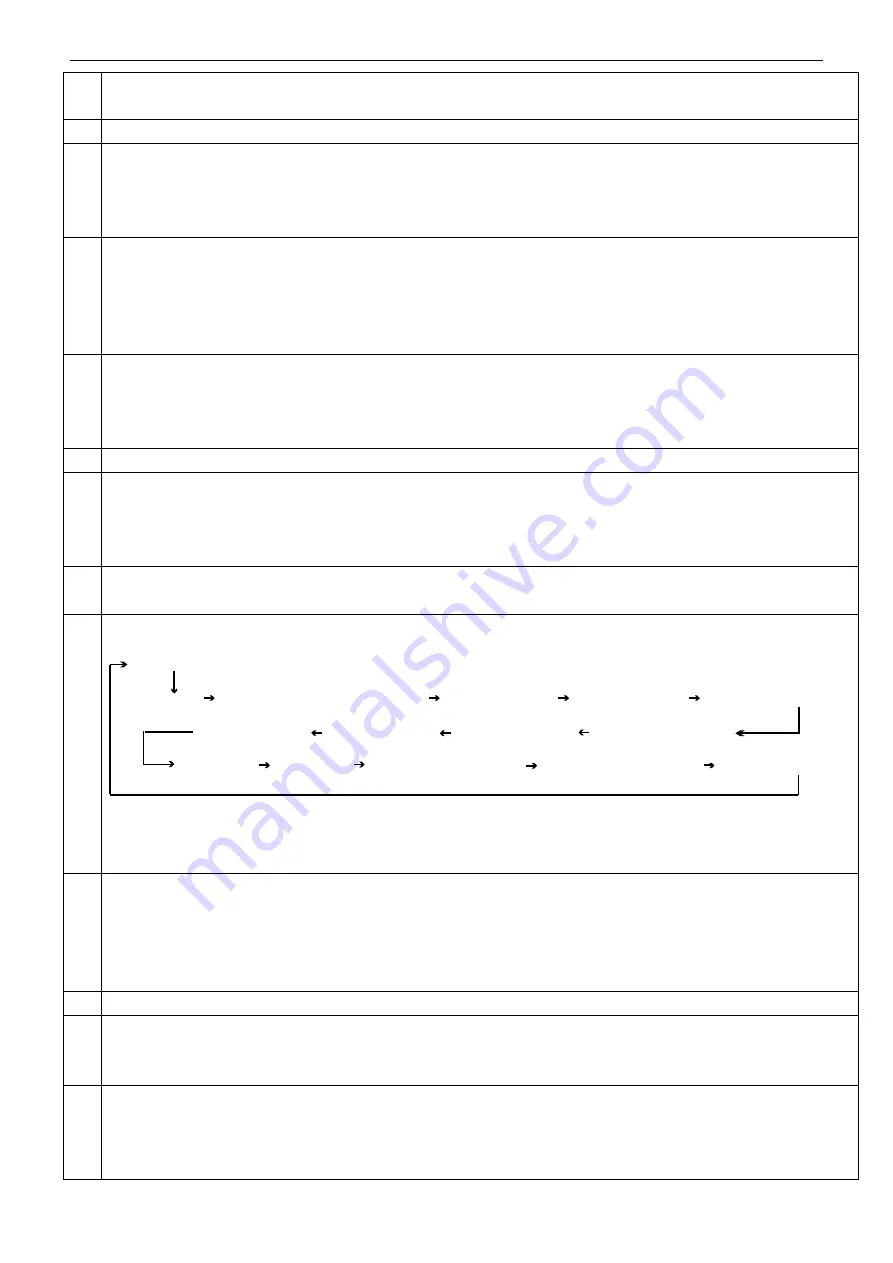

Spot check. The operating status of outdoor system can be observed through spot check, and specific display contents are

as shown in the following figure:

● Display contents of “operating mode”: 1. cooling; 2. heating; 4. pump; 8. Stand-by.

● Display contents of “number of online units”: the main unit can display the number of online units, and the slave unit

displays 0.

15

High-pressure protection of the system A and discharge temperature switch protection (Protection code P0).

High-pressure protection of the system B and discharge temperature switch protection (Protection code P2).

Low-pressure protection of the system A (Protection code P1).

Low-pressure protection of the system B (Protection code P3).

Constant speed compressor: connection of discharge temperature switch and high-pressure switch of the system in series.

16

Power phase detection(Fault code E8).

17

Water flow detection (Fault code of the main unit E9) is only valid for the main unit but invalid for subordinate units.

1) Main unit: if abnormal water flow occurs for the first and second time, the main unit board will display fault code E9.

2) Subordinate unit: (Water flow detection will not be done).

18

COM (I) 485 communication port (Fault code E2).

COM (O) is interconnected with P, Q and E of COM (I), used for RS-485 communication.

1) If faults occur between the wired controller and the main unit module, all modules will be shut down.

2) If faults occur between the main unit and subordinate units, the subordinate unit module suffering communication fault will

Normal display

Operating mode

Operating capability of the compressor B

Number of online units

Outdoor ambient temp. Temp. of the condenser A

Anti-freezing temp

Unit outlet-water temp

Unit inlet-water temp

Temp. of the condenser B

EXV opening A

EXV opening B

Operating current of system A

Operating current of system B

The last failure

Summary of Contents for Aqua Tempo Super Series

Page 48: ......

Page 62: ...MCAC ATSM 2013 11 Aqua Tempo Power Series with LAK air cooled scroll chiller unit 50Hz 61...

Page 69: ...Aqua Tempo Power Series with LAK air cooled scroll chiller unit 50Hz MCAC ATSM 2013 11 68...

Page 72: ...MCAC ATSM 2013 11 Aqua Tempo Power Series with LAK air cooled scroll chiller unit 50Hz 71...