Installation

Page 48

7. Additional Refrigerant Charge

•

After the vacuum drying process is carried out, the

additional refrigerant charge process need to be

performed.

•

The outdoor unit is factory charged with refrigerant.

The additional refrigerant charge volume is decided

by the diameter and length of the liquid pipe be-

tween indoor and outdoor unit. Refer the following

formula to calculate the charge volume.

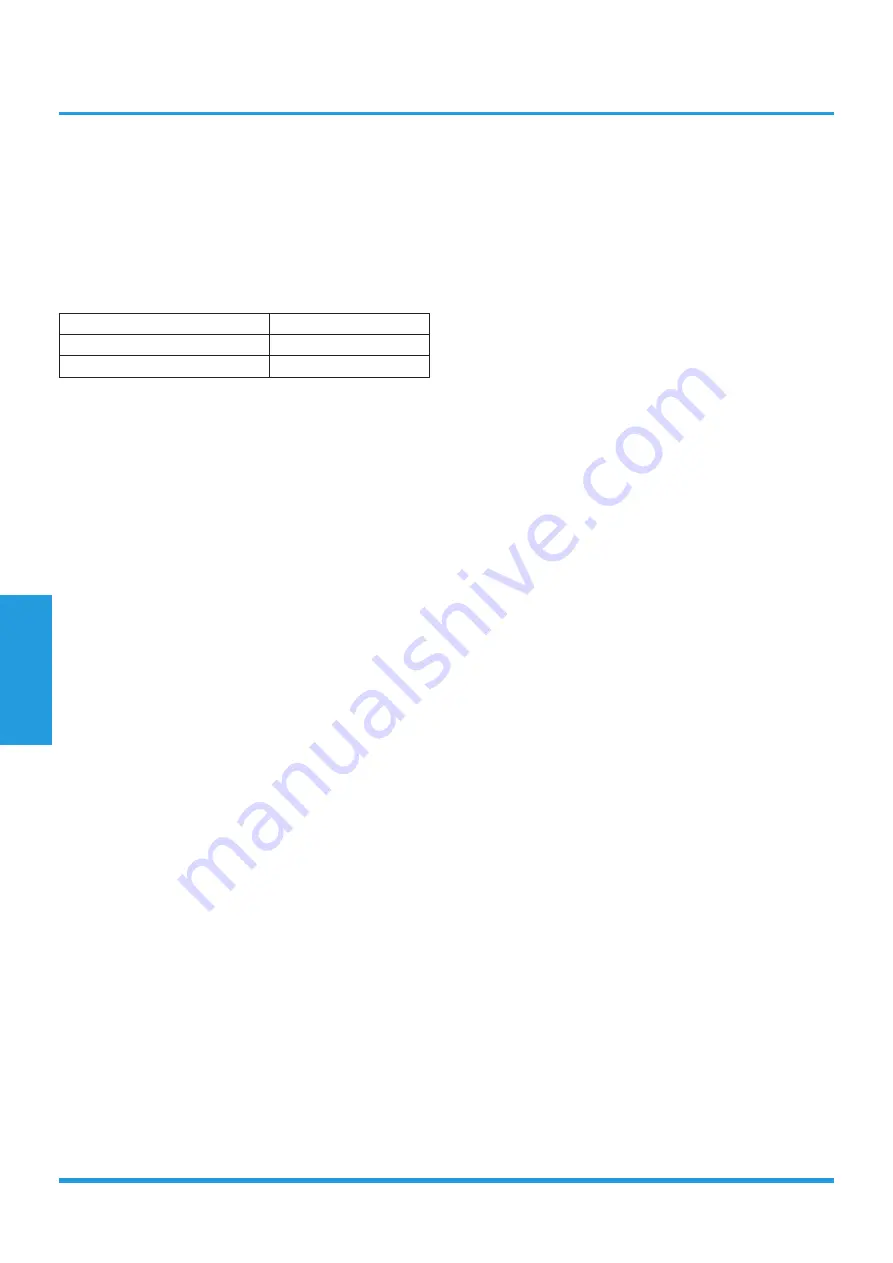

Diameter of liquid pipe (mm)

Formula

6.35

V=12g/m×(L-5)

9.52

V=24g/m×(L-5)

V:

Additional refrigerant charge volume (g).

L :

The length of the liquid pipe (m).

Note:

•

Refrigerant may only be charged after performed

the vacuum drying process.

•

Always use gloves and glasses to protect your hands

and eyes during the charge work.

•

Use electronic scale or fluid infusion apparatus to

weight refrigerant to be recharged. Be sure to avoid

extra refrigerant charged, it may cause liquid ham-

mer of the compressor or protections.

•

Use supplementing flexible pipe to connect refriger-

ant cylinder, pressure gauge and outdoor unit. And

The refrigerant should be charged in liquid state.

Before recharging, The air in the flexible pipe and

manifold gauge should be exhausted.

•

After finished refrigerant recharge process, check

whether there is refrigerant leakage at the connec-

tion joint part.(Using gas leakage detector or soap

water to detect).

8. Electrical and Gas Leak Checks

8.1 Electrical Safety Checks

After installation, confirm that all electrical wiring is

installed in accordance with local and national regulations,

and according to the Installation Manual.

8.1.1 Before test run

•

Check Grounding Work

Measure grounding resistance by visual detection and with

grounding resistance tester. Grounding resistance must be

less than 0.1 Ω.

Note:

This may not be required for some locations in the

US.

8.1.2 During test run

•

Check for Electrical Leakage

During the Test Run, use an electroprobe and multimeter

to perform a comprehensive electrical leakage test.

If electrical leakage is detected, turn off the unit

immediately and call a licensed electrician to find and

resolve the cause of the leakage.

Note:

This may not be required for some locations in the

US.

8.2 Gas Leak Checks

There are two different methods to check for gas leaks.

•

Soap and Water Method

Using a soft brush, apply soapy water or liquid detergent

to all pipe connection points on the indoor unit and

outdoor unit. The presence of bubbles indicates a leak.

•

Leak Detector Method

If using leak detector, refer to the device’s operation

manual for proper usage instructions.

8.3 After performing gas leak checks

After confirming that the all pipe connection points DO

NOT leak, replace the valve cover on the outside unit.

Summary of Contents for Forest MOAA31-12CN1-NB8

Page 1: ...FOREST R410A ONOFF CONTROL TM_AF_R410A_ONOFF_SA_NA_2008 TECHNICAL MANUAL ...

Page 8: ...Specifications Page 8 3 2 Outdoor Unit 12k ...

Page 9: ...Specifications Page 9 18k ...

Page 10: ...Specifications Page 10 24k ...

Page 12: ...Specifications Page 12 24k ...

Page 14: ...Specifications Page 14 18k 24k ...