M thermal Mono

28

202008

M

id

ea

M

th

er

m

al

M

on

o

Se

rv

ic

e

M

an

ua

l

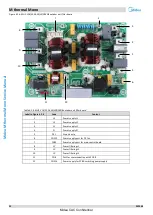

Table 4-2.1: MHC-V18(22,26,30)W/D2RN8 hydronic system main PCB

Label in Figure

4-2.1

Code

Content

1

CN21

Port for power supply

2

S3

Rotary dip switch

3

DIS1

Digital display

4

CN5

Port for ground

5

CN28

Port for variable speed pump power input

6

CN25

Port for IC programming

7

S1,S2,S4

Dip switch

8

CN4

Port for USB programming

9

CN8

Port for Flow switch

10

CN6

Port for temp. sensors (T2,T2B,TW_out,TW_in, T1,)

11

CN24

Port for temp. sensor(Tbt1, The balanced water tank of up temp. sensor)

12

CN16

Port for temp. sensor(Tbt2, The balanced water tank of up temp. sensor)

13

CN13

Port for temp. sensor(T5, domestic hot water tank temp. sensor)

14

CN15

Port for temp. sensor(Tw2, The outlet water for zone 2 temp. sensor)

15

CN18

Port for temp. sensor(Tsolar, Solar panel temp. sensor)

16

CN17

Port for variable speed pump communication

17

CN31

Control port for room thermostat (heating mode)(HT)/Control port for room thermostat (cooling

mode)(CL)/Power port for room thermostat(COM)

18

CN35

Port for smart grid (grid signal, photovoltaic signal)

19

CN36

Port for remote switch, temperature board

20

CN19

Communicate port between indoor unit and outdoor unit

21

CN14

Port for communication with the wired controller

22

CN30

Communicate port between indoor unit and outdoor unit, port for communication with the wired

controller, internal machine parallel

23

CN7

Port for antifreeze E-heating tape(external), additional heat source, compressor run/defrost run

24

CN11

Control port for tank booster heater, internal backup heater 1, input port for solar energy, Port for room

thermostat, SV1(3-way valve), SV2(3-way valve), SV3(3-way valve), zone 2 pump, outside circulation

pump, solar energy pump, DHW pipe pump,

25

CN2

Feedback port for external temp. switch(shorted in default)

26

CN1

Feedback port for temperature switch(shorted in default)

27

CN22

Control port for backup heater1/booster heater/Reserved

28

CN41

Port for anti-freeze electric heating tape

29

CN42

Port for anti-freeze electric heating tape

30

CN29

Port for anti-freeze electric heating tape

31

IC39

EEPROM

Midea CAC Confidential