CONTENTS

1. Precaution .................................................................................................................................................... 1

1.1 Safety Precaution .......................................................................................................................... 1

1.2 Warning ......................................................................................................................................... 1

2. Function ........................................................................................................................................................ 6

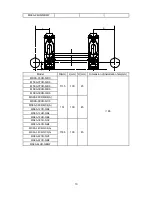

3. Dimension .................................................................................................................................................... 9

3.1 Indoor Units ................................................................................................................................... 9

3.2 Outdoor Units .............................................................................................................................. 12

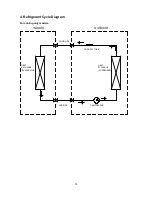

4. Refrigerant Cycle Diagram ....................................................................................................................... 14

5. Wiring Diagram .......................................................................................................................................... 16

5.1 Indoor Units ................................................................................................................................. 16

5.2 Outdoor Units .............................................................................................................................. 21

6. Installation details ...................................................................................................................................... 29

6.1 Wrench torque sheet for installation ........................................................................................... 29

6.2 Connecting the cables ................................................................................................................ 29

6.3 Pipe length and the elevation ..................................................................................................... 30

6.4 Installation for the first time ......................................................................................................... 31

6.5 Adding the refrigerant after running the system for many years ................................................ 34

6.6 Re-installation while the indoor unit need to be repaired ........................................................... 35

6.7 Re-installation while the outdoor unit need to be repaired ......................................................... 37

7. Operation characteristics ......................................................................................................................... 40

8. Electronic function .................................................................................................................................... 41

8.1 Abbreviation ................................................................................................................................ 41

8.2 Display function ........................................................................................................................... 41

8.3 Main Protection ........................................................................................................................... 42

8.4 Operation Modes and Functions ................................................................................................. 43

9. Troubleshooting ......................................................................................................................................... 52

9.1 Indoor unit error display .............................................................................................................. 52

9.2 Diagnosis and Solution ............................................................................................................... 54

Summary of Contents for MA9A-24HR-QB4W

Page 19: ...17 MS9A 18CR QB6...

Page 20: ...18 MS9A 18CR PC4W A MS9A 05CR QD0 MS9A 09CR QB6 A MS9A 09CR QB6 MS9A 09CR QC0 MS9A 09CR QC4 A...

Page 21: ...19 MS9A 12CR QC4 A MS9A 18CR QC0 MS9A 18CR QC2 MS9A 18CR QB8 MS9A 18CR QC4 A MS9A 18CR QC0 A...

Page 22: ...20 MS9A 21HR QB6W MA9A 24HR QB4W MS9A 22CR QC0 MS9A 22CR QB8...

Page 23: ...21 5 2 Outdoor Units MOK2 07C QB6 MOK6 09C QB6 MOA1 12C QB6 MOA2 12C QB6...

Page 24: ...22 MOB 18C QB6...

Page 25: ...23 MOK 07H QB6 MOK3 09H QB6 MOB 12H QB6 MOA1 12H QB4 MOA2 12H QB6...

Page 27: ...25 MOB3 18C QB8 MOC2 18C QC0 MOB1 18CP QC0 MOB2 18CP QC0...

Page 28: ...26 MOB 18H QB6...

Page 29: ...27 MOF 18C QC4W MOF4 21H QB6W...