36

5). Operate the air conditioner at the cooling cycle and stop it when the gauge indicates 0.1MPa.

6). Set the 3-way valve to the closed position immediately.

Do this quickly so that the gauge ends up indicating 0.3 to 0.5Mpa.

Disconnect the charge set, and tighten the 2-way and 3-way valve’s stem nuts.

Use a torque wrench to tighten the 3-way valves service port cap to a torque of 18N.m.

Be sure to check for gas leakage.

2. Air purging by the refrigerant

Procedure:

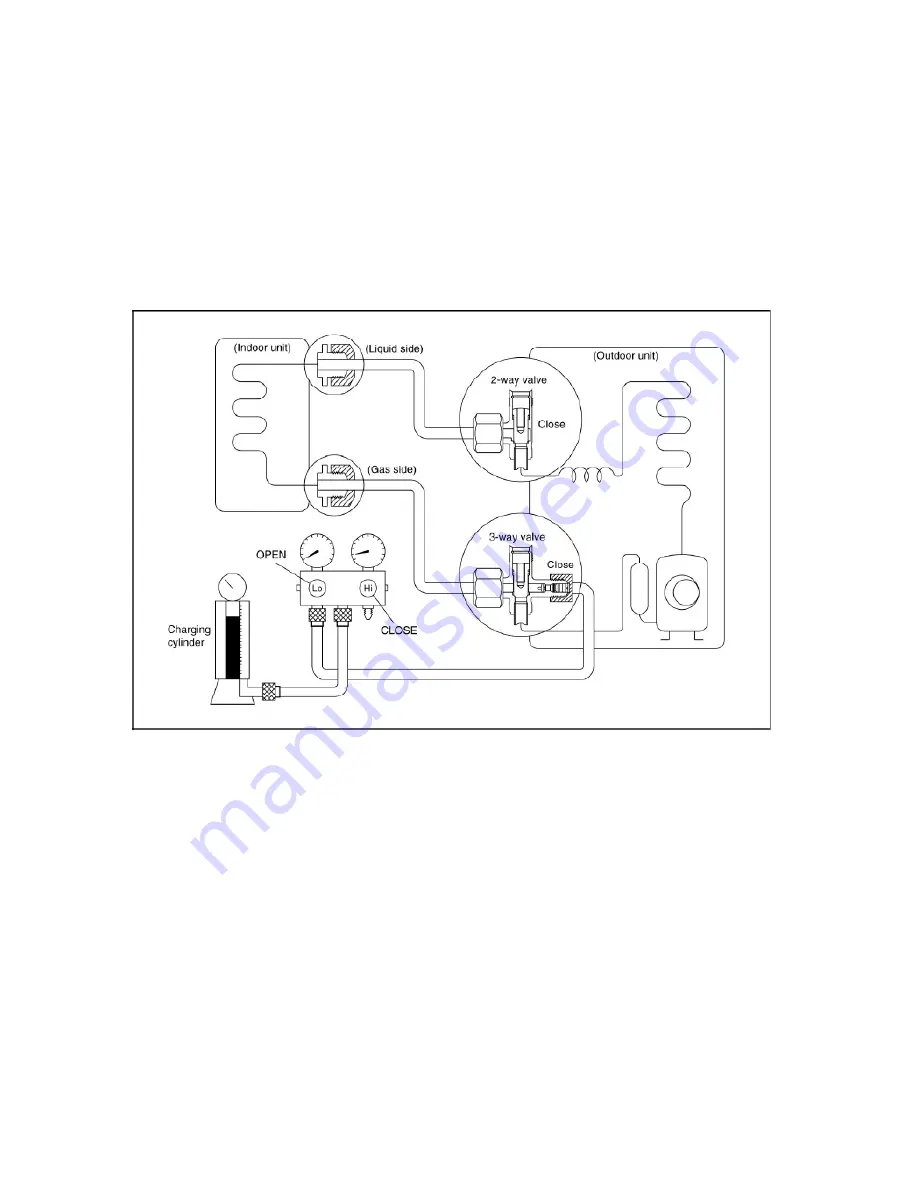

1). Confirm that both the 2-way and 3-way valves are set to the closed position.

2). Connect the charge set and a charging cylinder to the service port of the 3-way valve.

Leave the valve on the charging cylinder closed.

3). Air purging

Open the valves on the charging cylinder and the charge set. Purge the air by loosening the flare nut on

the 2-way valve approximately 45’ for 3 seconds then closing it for 1 minute; repeat 3 times.

After purging the air, use a torque wrench to tighten the flare nut on the 2-way valve.

4). Check the gas leakage

Check the flare connections for gas leakage.

5). Discharge the refrigerant

Summary of Contents for MA9A-24HR-QB4W

Page 19: ...17 MS9A 18CR QB6...

Page 20: ...18 MS9A 18CR PC4W A MS9A 05CR QD0 MS9A 09CR QB6 A MS9A 09CR QB6 MS9A 09CR QC0 MS9A 09CR QC4 A...

Page 21: ...19 MS9A 12CR QC4 A MS9A 18CR QC0 MS9A 18CR QC2 MS9A 18CR QB8 MS9A 18CR QC4 A MS9A 18CR QC0 A...

Page 22: ...20 MS9A 21HR QB6W MA9A 24HR QB4W MS9A 22CR QC0 MS9A 22CR QB8...

Page 23: ...21 5 2 Outdoor Units MOK2 07C QB6 MOK6 09C QB6 MOA1 12C QB6 MOA2 12C QB6...

Page 24: ...22 MOB 18C QB6...

Page 25: ...23 MOK 07H QB6 MOK3 09H QB6 MOB 12H QB6 MOA1 12H QB4 MOA2 12H QB6...

Page 27: ...25 MOB3 18C QB8 MOC2 18C QC0 MOB1 18CP QC0 MOB2 18CP QC0...

Page 28: ...26 MOB 18H QB6...

Page 29: ...27 MOF 18C QC4W MOF4 21H QB6W...