MCAC-PDSM-2013-04 Midea Precision AC Technical Manual-Down Delivery Series

91

the inverter output to stop the motor and make it stay free running condition. If there is alarm, the

inverter will display alarm code, and will not cut off the inverter output during alarm state, the

motor still be controlled by the inverter.

Many methods of inverter error reset: Press the

Reset

button in keypad of inverter, reset function

of terminals, or if necessary, power off the main power for a while then can reset the error. If error

has been solved, the inverter will recover to normal operation. If error still not has been solved,

the inverter will trip out again.

The alarm reset of inverter only effect by operate the

Esc

button in keypad of inverter.

When no display after power on:

1. Use the multimeter to check whether input power of inverter is same as the rated voltage.

2. Check whether the

Charge

lamp whether lights up.

3. If the above are normal, then maybe the power switch has error.

When the inverter does not run after the motor operation:

Cut off the connecting wire between inverter and motor, operate the inverter in 50Hz, and use

multimeter to check whether there is equivalent AC between U, V and W. Use simulate voltage

meter for measurement (the range is AC500V). If there is not equivalent voltage or no voltage,

then the inverter had been damaged.

Notes:

Between U, V and W are high –frequency impulse.

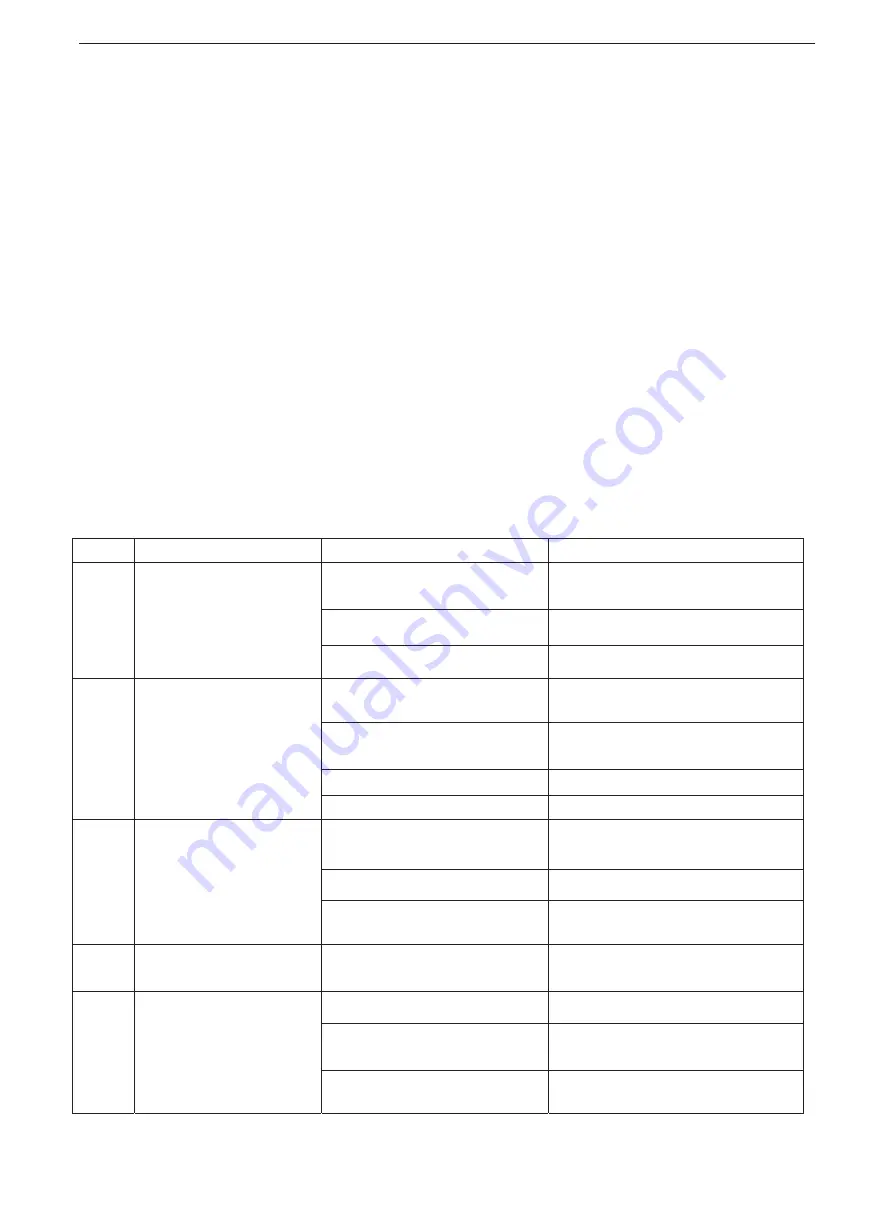

Code Type

Error

reason

Solutions

E001

Over current error, current is

higher than 150% of

Maximum current.

Speed up and down times too

short.

Extend the speed up and down time.

The inverter power is too small

Select a large power inverter.

Voltage is too low.

Check the input voltage.

E002

Power module error

Speed up and down time is too

short.

Extend the speed up and down time.

The inverter output side is short

circuit.

Check the insulation of motor.

Power module is damaged

Replace the module.

Outer disturb.

Find out disturb and

eliminate it.

E003

Bus overvoltage error, the

value is more than 570V.

Speed down time is too short,

regenerated energy too large.

Extend the speed down time.

Voltage is too high.

Check the input voltage.

Load inertia is too large,

regenerated energy too large.

Select a large power inverter.

E004

Bus voltage error, the value

is less than 171V.

Voltage of power supply is too low.

Check the input voltage.

E005

Motor load error, the motor

current is higher than

standard inverter current.

Voltage is too low.

Check the input voltage.

Load inertia is too large.

Check the load inertia, adjust torque

lifting capacity.

Not correct standard current setting

of motor.

Reset the standard current of motor.