Troubleshooting

194

Electrical Control System

2. Troubleshooting

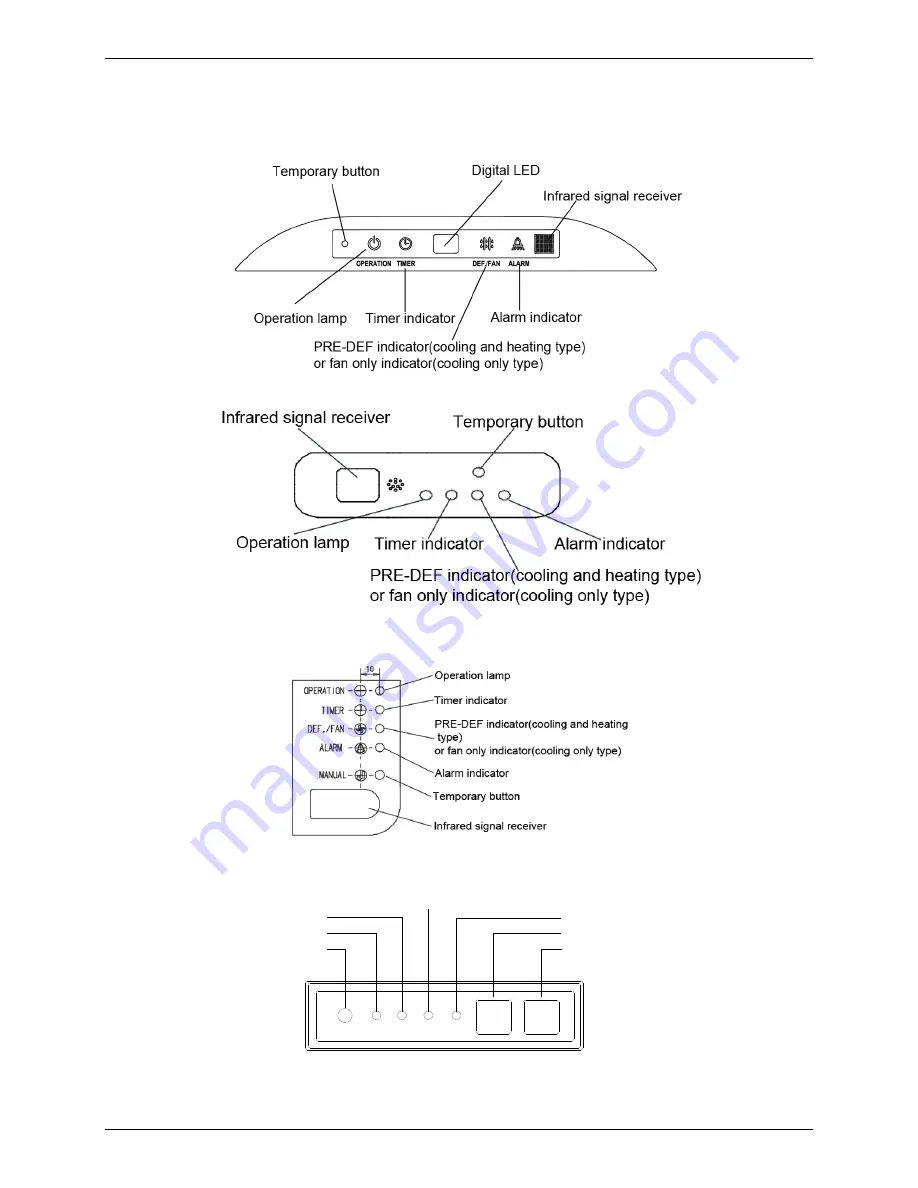

2.1 Display board

2.1.1 Icon explanation on indoor display board (Big cassette).

2.1.2 Icon explanation on indoor display board (Compact cassette &

High static pressure Duct).

2.1.3 Icon explanation on indoor display board (Ceiling & floor)

2.1.4 Icon explanation on indoor display board (A5 Duct)

OPERATION TIMER DEF./FAN

ALARM

Temporary button

Operation lamp

Timer indicator

Infrared signal receiver

Alarm indicator

PRE-DEF indicator(cooling and heating type)

or fan only indicator(cooling only type)

MANUAL

Display digital tube

Summary of Contents for mcd-24hrdn1

Page 1: ...DC INVERTER SERIES Service Manual 2013 LIS B 1306...

Page 2: ......

Page 4: ......

Page 15: ...Dimensions 11 2 Dimensions...

Page 16: ...Service Space 12 3 Service Space...

Page 17: ...Wiring Diagrams 13 4 Wiring Diagrams MCA2 12HRDN1 Q MCA2 18HRDN1 Q...

Page 21: ...Field Wiring 17 10 Field Wiring MCA2 12HRDN1 Q MCA2 18HRDN1 Q...

Page 22: ...Field Wiring 18 MCA2 12HRDN1 Q MCA2 18HRDN1 Q...

Page 28: ...Service Space 26 Four way Cassette Type 3 Service Space 1000mm 1000mm 1000mm 1000m m...

Page 29: ...Wiring Diagrams Four way Cassette Type 27 4 Wiring Diagrams MCC 24HRDN1 Q MCC 30HRDN1 Q...

Page 30: ......

Page 31: ...Wiring Diagrams Four way Cassette Type 21 MCC 36HRDN1 Q MCC 48HRDN1 Q MCC 60HRDN1 R...

Page 36: ...Field Wiring 26 Four way Cassette Type 10 Field Wiring Wiring chart...

Page 43: ...Service Space Super Slim Cassette Type 33 3 Service Space 1000mm 1000mm 1000mm 1000m m...

Page 58: ...Wiring Diagrams 48 Duct Type MTB 36HWDN1 Q MTB 48HWDN1 Q MTB 60HWDN1 R...

Page 65: ...Field Wiring Duct Type 55 10 Field Wiring...

Page 66: ...Field Wiring 56 Duct Type Air conditioner link circuit For model 12 For model 18 60...

Page 72: ...Wiring Diagrams 62 Ceiling Floor Type MUB 18HRDN1 Q MUB 24HRDN1 Q MUB 30HRDN1 Q...

Page 79: ...Field Wiring Ceiling Floor Type 69 10 Field Wiring...

Page 80: ...Field Wiring 70 Ceiling Floor Type For model 12 For model 18 60...

Page 82: ......

Page 85: ...Features Console Type 75...

Page 86: ...Dimensions 76 Console Type 2 Dimensions MFA 12HRDN1 Q MFA 18HRDN1 Q...

Page 87: ...Service Space Console Type 77 3 Service Space...

Page 88: ...Wiring Diagrams 78 Console Type 4 Wiring Diagrams MFA 12HRDN1 Q MFA 18HRDN1 Q...

Page 93: ...Field Wiring Console Type 83 10 Field Wiring...

Page 94: ...Field Wiring 84 Console Type...

Page 97: ...Dimensions High Static Pressure Duct 87 2 Dimensions MHD 36HRDN1 Q MHD 48HRDN1 Q MHD 60HRDN1 R...

Page 104: ...Field Wiring 94 High Static Pressure Duct 10 Field Wiring...

Page 108: ...Service Space 98 3rd Generation Ceiling Floor Type 3 Service Space...

Page 114: ...Field Wiring 104 3rd Generation Ceiling Floor Type 9 Field Wiring MUE 48HRDN1 Q MUE 60HRDN1 R...

Page 118: ...Service Space 108 GA Floor standing Type 3 Service Space...

Page 122: ...Accessories 112 GA Floor standing Type 7 Accessories...

Page 124: ...Field Wiring 114 GA Floor standing Type 9 Field Wiring MFGA 24ARDN1 QC2...

Page 125: ...Field Wiring GA Floor standing Type 115 MFGA 36ARDN1 R MFGA 48ARDN1 R MFGA 60ARDN1 R...

Page 129: ...Dimensions Outdoor Units 119 New MOU 48HDN1 Q MOU 48HDN1 R MOU 60HDN1 R...

Page 133: ...Wiring Diagrams Outdoor Units 123 4 Wiring Diagrams MOU 12HDN1 Q MOU 18HDN1 Q...

Page 134: ...Wiring Diagrams 124 Outdoor Units MOU 24HDN1 Q 220075301400 MOU 24HDN1 Q 220075302030...

Page 135: ...Wiring Diagrams Outdoor Units 125 MOU 30HDN1 Q MOU 36HDN1 Q 220075501600...

Page 136: ...Wiring Diagrams 126 Outdoor Units MOU 36HDN1 Q 220075501990...

Page 137: ...Wiring Diagrams Outdoor Units 127 MOU 48HDN1 Q MOU 48HDN1 Q New Body...

Page 138: ...Wiring Diagrams 128 Outdoor Units MOU 36HDN1 R MOU 48HDN1 R MOU 60HDN1 R...

Page 139: ...Wiring Diagrams Outdoor Units 129 MOU 48HDN1 R MOU 60HDN1 R New Body...

Page 224: ...Troubleshooting 214 Electrical Control System 2 4 2 10 P0 malfunction...

Page 225: ...Troubleshooting Electrical Control System 215 2 4 2 11 P1 malfunction Only for 30K 60K...

Page 226: ...Troubleshooting 216 Electrical Control System 2 4 2 12 P2 malfunction Only for 30K 60K...

Page 227: ...Troubleshooting Electrical Control System 217 2 4 2 13 P3 malfunction...