Summary of Contents for MCHS-09NIH1

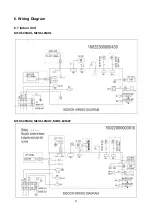

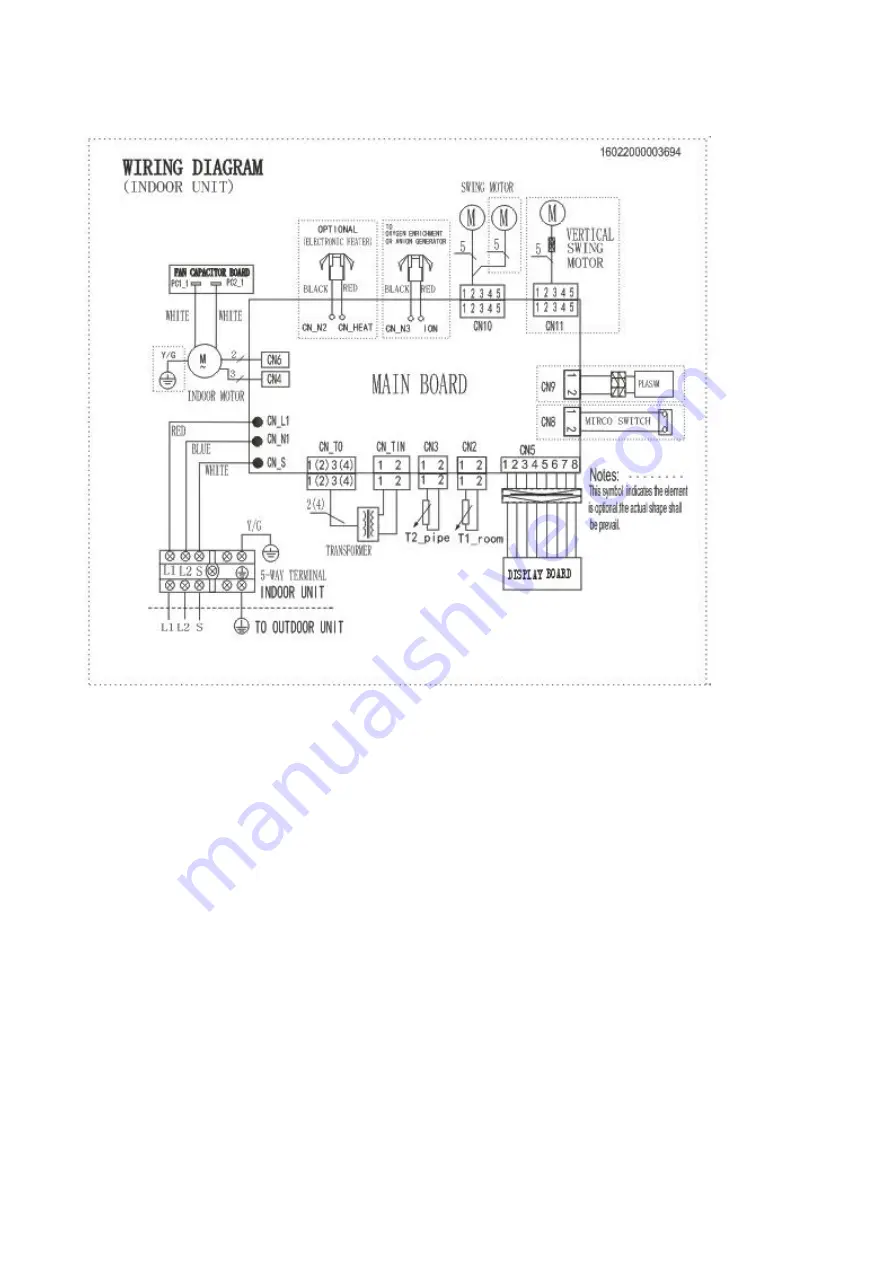

Page 11: ...9 6 Wiring Diagram 6 1 Indoor Unit MEHS 09NiH1 MEHS 12NiH1 MEHS 09NiH2 MEHS 12NiH2 MEHS 18NiH2...

Page 12: ...10 MEHS 22NiH2...

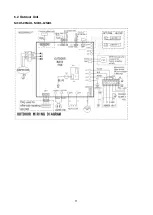

Page 13: ...11 6 2 Outdoor Unit MCHS 09NiH1 MCHS 12NiH1...

Page 14: ...12 MCHS 09NiH2 MCHS 12NiH2...

Page 15: ...13 MCHS 18NiH2 MCHS 22NiH2...

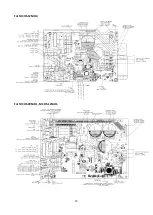

Page 16: ...14 For MCHS 12NiH2 For MCHS 09NiH1 MCHS 12NiH1...

Page 17: ...15 For MCHS 09NiH2 For MCHS 18NiH2...

Page 18: ...16 For MCHS 22NiH2...

Page 50: ...48 P W P N...