37

MCHSU-48CSH2

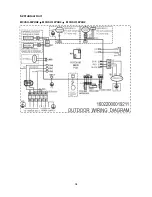

PCB board of

MCHSU-09PHH2, MCHSU-12PHH2, MCHSU-18PHH2

Suction

Exhaust

+

17122200000309

HuiQi

TestPort

1

1

HEAT

4-WAY

W

BLUE

BLACK

RED

V

U

TP

T3

T4

No

NO

NO

YES

Low-Fre

No

Have

YES

Have

Temp-Pro

Rdi

Ripm

11

PMV

44

15V

17V

[V1.8] 2015-01-16

7815

22

1

34

REACTOR

311 TEST

7805

N-IN

DC-FAN

AC-FAN

L-IN

S

KFR-72W/BP2-(311+0515+PSS30S92F6-AG+6822+HEAT).D.13.WP2.1

12V

5V

CN3

DSA1

K

A

K

D5

R18

R46

R107A

R515A

R316A

R18A

IC403

D

4

C21

R54

R55

R68

R69

R5

6

R90

C14

J4

R16

R52

J5

+

LED

1

R78

R142

R141

R155

R154

R153

R152

R151

R150

C3

R1

08

R10

7

RC2

RC4

RC1

RC3

C1

FUSE1

65T 250V30A

ZR1

ZR2

CN30

R109

R58

R61

R60

R5

9

C3

01

C76

C31

2

R31

5

C83

C85

C8

6

C

9

1

R156

R158

R16

9

R17

0

R1

71

R1

72

IC34

D11

R15

7

R159

C3

10

C

3

06

C30

8

C311

C30

7

C309

R110

E305

C302

+

DZ301

Q3

R7

5

R84

C1

03

CN28

CN29

CN6-1

CN6

CN13

CN12

CN2

CN8

CN7

CN22

DR

CN21

DR

R102

J6

PTC1

CN414

R127

C105

+

E5

IPM

2

C5

01

C50

3

C

5

07

C

5

08

C50

9

C51

0

C51

1

C51

2

C5

17

+

DZ501

R50

1

R5

02

R503

R5

04

R5

05

R506

R50

9

R51

0

R51

1

R51

2

R51

3

R5

14

R52

3

C502

C5

05

+

DZ502

R515

R522

+

DZ504

C504

R316

~

~

IN

AC

-

+

R101

R100

R71

C42

CN20

RY5

CN16

CN18

NTC4

C8

C5

13

C514

C5

15

C516

R516

R517

R518

R519

R520

R521

C27

IC7

24LC512

33

49

17

1

IC9

R53

IC101

R160

+

E4

+

E3

R83

R82

R81

R80

R79

R50

C47

C20

R322

R321

R320

Q2

IC405

+

E10

R120

R1

67

R166

R32

+

E1

R12

+

LED3

R41

2

R4

13

R414

R415

Rd

i

R

ipm

R13

CN24

R72

R8

R87

R74

J3

IC17

+

E24

D2

R124

C2

J2

J

1

C77

A

C

A

C

+

-

BR1

C13

D3

R7

RY3

RY4

RY2

CN

5

R23

R24

R25

R26

R27

C7

4

C75

RY1

+

E14

C9

C17

C18

C19

C23

C24

C26

C32

C33

C35

C36

C37

C39

C43

C48

C49

C52

C65

C67

C

7

8

C87

C8

9

C90

C92

C147

C15

3

C25

CN9

CN23

CN39

+

E17

+

E23

+

E28

IC8

24LC08

IC12

24LC08

IC14

+

LED2

OSC1

R5

R30

R31

R40

R41

R42

R48

R49

R62

R64

R65

R66

R70

R73

R76

R77

R86

R92

R97

R16

1

R1

62

R16

3

R164

R165

R1

76

R177

R419

X1

C58

+

+

E405

IC404

R45

Q1

C15

C22

R21

R22

R2

8

R29

R33

+

E22

R3

R4

R121

C5

+

E6

R10

C28

C4

CN38

IC10

C79

C80

D7

C6

R14

8

R6

3

C506

R50

7

R508

+

E11

R106

C73

IC21

PC817

IC31

PC817

R175

R178

C409

IC402

C403

IC11

+

E402

D401

C401

R403

C411

C40

C50

D403

R401

R405

R40

6

R404

+

E404

D402

D404

C4

08

C402

+

E403

R40

7

R408

C404

C110

+

E409

+

E4

0

1

R402

C405

10

9

7

6

5

4

3

1

T401

C406

C407

D13

D14

+

E406

+

E407

+

E408

+

E502

+

E503

+

E504

+

DZ5

03

CN25

R6

R9

CN

60

IC406

IC407

C7

D1

R1

R13

7

IC2

PC851

IC1

PC817

R2

R126

R125

R123

R122

R119

R118

R117

R1

5

R14

C99

C98

C9

7

C96

C95

C94

C93

C66

D

20

R17

CN17

CN

1

0

CN1

C41

R38

C45

C44

R13

6

R135

R134

R1

04

D12

D10

C5

4

+

D8

D9

R57

R20

C242

C24

3

C2

44

R89

E2

R67

C84

C10

C11

IC4

C1

2

C38

R3

4

R47

R88

IC32

R39 R35

R36

R19

+

DZ6

R37

C46

C51

C53

CN19

+

DZ2

+

E27

IC3 PC817

IC5

PC817

Q8

R43

R44

R85

R91

R93

R95

R96

R99

D15

R

5

1

+

E410

+

E8

C60

C61

E302

E303

E304

C62

V N1

V P1

U

P

V UB

U +

W

V +

V

W +

U -

V VB

V W

B

F O

W -

V -

N V

N W

N U

V NC

C IN

IPM1

+

DZ304

+

DZ303

+

DZ302

C314

C3

16

C318

C30

C34

C31

ZR3

ZR4

C82

L1

R11

R14

0

CN27

E301

R168

IGBT1

connect to the DR module

connect to earth

fuse 250V 30A

connect to reactance

290-330VDC standby

210-300VDC running

power supply 208-230V AC connect to the terminal

connect to 4-way valve

when 4-way is on, output 208-230V AC

AC FAN mototr

connect to compressor heater

when heater is on, output 208-230V AC

1 low speed

2 hign speed

3 ground

external drive motor

connect to DC motor

0V AC standby

10~200V AC’ running

U

V

W

connect to electric expansion valve

6

5

4

3

2

1

+12VDC

+12VDC

+12V DC pulse wave between( +4)-GND

+12V DC pulse wave between( +3)-GND

+12V DC pulse wave between( +2)-GND

+12V DC pulse wave between( +1)-GND

EEPROM Programmer Port

reserve

test port

Connect to PC

communication

V

U

W

connect to PC communication

test port

LED2

(

red

)

&LED3

(

green

)

: status light

combination LED2 and LED3 show errors

(

refer to the attechment Word

)

LED: status light

(

yellow

)

slow flicker

:

standby

(

0.5Hz

)

quick flicker

:

error

(

2Hz

)

continuous light: running

internal drive motor

6 5 4 3 1

rota

te

spe

ed

feedba

ck

signa

l

0-15

V

squa

re signal

d

rive power v

o

ltag

e:

+

15VDC

D

C negative pol

e: GND

DC

posi

tive

pole

P:

315V

DC

exhaust temp. sensor

pipe temp.sensor& room temp. sensor

TP T4 T3

7 6 5 4 3 2 1

RT

+5V

DC

RT

RT

+

5V

D

C

+5V

DC

CN5/CN4 connect to chassis heater

when heater is on, output 208-230V AC

connect to DC motor

0V AC standby

10~200V AC’ running

bridge

IGBT

fast recovery diode

(FRD)

IPM for compressor

IPM for DC FAN

reserve

P

N

Summary of Contents for MCHSU-09PHH2

Page 7: ...5 2 2 Part names of Indoor Outdoor units Cassette Unit...

Page 8: ...6 Duct Units...

Page 9: ...7 Console...

Page 10: ...8 Ceiling floor Units...

Page 28: ...26 Console Unit Ceiling floor Units 39 37 39 37in 3 94in 39 37in 1 38in...

Page 32: ...30 MEHSU 09CHN2 MEHSU 12CHN2 MEHSU 36CSC2 MEHSU 48CSC2...

Page 33: ...31 MEHSU 36CSD2 MEHSU 48CSD2...

Page 34: ...32 MEHSU 18CHF2 MEHSU 24CHF2 MEHSU 36CSF2...

Page 35: ...33 MEHSU 48CSF2 MEHSU 36CSF2 MEHSU 48CSF2...

Page 36: ...34 6 2 Outdoor Unit MCHSU 09PHH2 MCHSU 12PHH2 MCHSU 18PHH2...

Page 37: ...35 MCHSU 24PHH2...

Page 38: ...36 MCHSU 36CSH2...

Page 41: ...39 For MCHSU 48CSH2...

Page 44: ...42 MEHSU 09CHD2 Code 0 Code 1 Code 2 Code 3 Code 4...

Page 45: ...43 MEHSU 12CHD2 Code 0 Code 1 Code 2 Code 3 Code 4...

Page 46: ...44 MEHSU 18CHD2 Code 0 Code 1 Code 2 Code 3 Code 4...

Page 47: ...45 MEHSU 24CHD2 Code 0 Code 1 Code 2 Code 3 Code 4...

Page 48: ...46 MEHSU 36CSD2 Code 0 Code 1 Code 2 Code 3 Code 4...

Page 49: ...47 MEHSU 48CSD2 Code 0 Code 1 Code 2 Code 3 Code 4...

Page 58: ...56 12 Field Wiring 36K 48K...