4. Table 5

Pipe size and connection of indoor unit

Liquid side

Gas side

F

19.0

flaring nut

9.53

flaring nut

130m

150m

4 0 m

5 0 m

3 0 m

1 5 m

L1+L2+L3+L4+L5+L6

L1+L3+L4+L5+L6+i

L3+L4+L5+L6+i

+a+b+c+d+e+f+g+h+i

20HP

2 5 0 m

3 0 0 m

20HP

h 15m

L

1

L

2

L

3

L

4

L

5

L

6

a

b

c

d

e

f

g

h

i

1

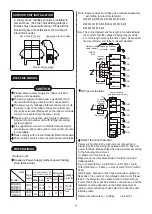

Table 1

Pipe size and connection of outdoor unit

2

Table 2

3

1

2

Type of pipe

4

Table 4

Size of main pipe

A: Capacity of all the indoor units.

A(horsepower)

A

12

12

A

16

16

A

24

24

A

32

32

A

48

48

A

64

F

28.6/

F

12.7

F

38.0/

F

19.0

F

45.0/

F

22.0

MDV-BY101

MDV-BY102(A) (refit)

MDV-BY102(A)

MDV-BY103(A)

Size of main pipe connecting multi-modules (unit: mm)

3

Table 3

F54

.0/

F

25.0

MDV-BY104

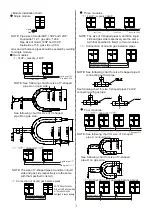

4.Take 30HP outdoor unit for example:

1 a 2

b 3

c

4

d

5

e

6

f 13

7

8

9

10

11

12

#

1

7#

(5P)

(5P)

(5P)

(5P)

(3P)

(2P)

5P

#

2

#

3

#

4

#

5

#

6

Determine pipe size

1. Branch pipes: No.7, 8, 9, 10,11, 12 and 13

the size is

F

19.0/

F

9.53

2. 6# and 7# indoor units connect with pipe 6, total HP is 2+5=7P

10P

pipe size is

F

28.6/

F

12.7, model of branch join: MDV-BY101

3. Subordinate indoor units of pipe 5 are :5#, 6# and 7#, total HP is 3+2+5=10P

10P,

pipe size is

F

28.6/

F

12.7, model of branch joint: MDV-BY101

4. Subordinate indoor unis of pipe 4 are 4#, 5#, 6# and 7#, total HP is 5+3+2 +5=15P

16P, pipe size is

F

38.0/

F15.9

, model of branch joint:MDV-BY102(A)

5. Subordinate indoor units of pipe 3 are 3#, 4#, 5#, 6# and 7#, total HP is 5+5+3+2+5=

20P

24P, pipe size is

F

38.0/

F19.0

, model of branch joint:MDV-BY102(A)

6. Subordinate indoor units of pipe 2 are 2#

7#, totel HP is 5+5+5+3+2+5=25P

32P,

pipe size is

F

45.0/

F

22.0, model of branch joint:MDV-BY103(A)

7. Pipe 1 is main pipe, the size is

F

45.0/

F

22.0, model of branch joint: MDV-BY103(A)

MDV-BY105

f

9.53

f

12.7

0.065kg

0.115kg

f

19.0

f

22.0

0.290kg

0.380kg

f

25.0

0.580kg

f

15.9

0.190kg

f

28.6

0.760kg

F

38.0/

F15.9

F67

.0/

F28.6

NOTE: The size of T-shaped pipe X connecting with

oil pipe is the same with that specified in three modules.

The sizes of T-shaped pipes Y and Z connecting with

gas pipe are the same with that specified in three modules.

Liquid side

12.7(flaring nut)

12.7(flaring nut)

12.7(flaring nut)

15.9(flaring nut)

15.9(flaring nut)

MDV-D400W/CS

MDV-D450W/CS

MDV-D335W/CS

MDV-D280W/CS

MDV-D252W/CS

Model

Gas side

28.6(welding)

28.6(welding)

28.6(welding)

38.0(welding)

38.0(welding)

Capacity of parallel unit A (HP)

Pipe size (gas/liquid)

Name

Branch pipe

Main pipe

Pipe location

Directly connect to indoor unit

Not directly connect to indoor unit

Number in chart

Main pipe(gas side/liquid side)

Branch joint

Note: Select the first branch joint based on the capacity of outdoor

unit, which should be larger than other branch joints.

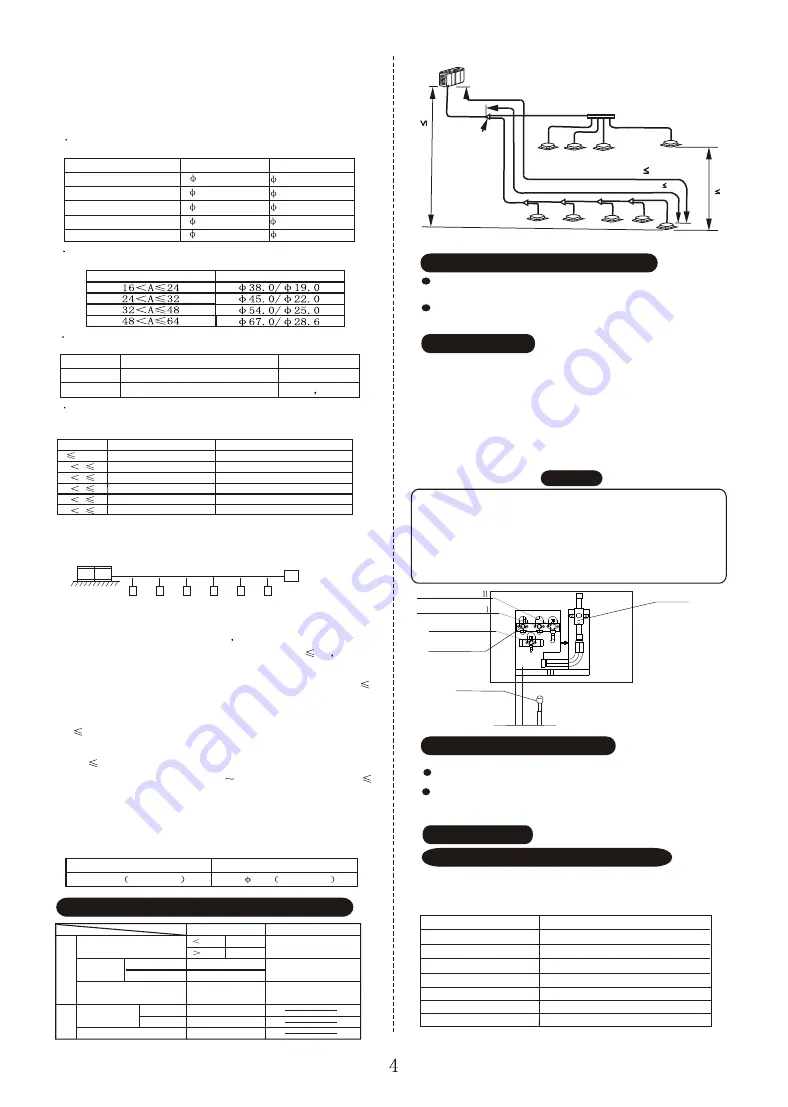

Length and Drop Height Permitted of the Refrigerant piping

Permitted value

Total Pipe Length (Actual)

Max Piping (L)

Indoor Unit to Indoor Unit Drop Height(h)

Indoor-Outdoor Unit

Drop Height(H)

Piping (farthest from the first line

pipe branch) Equivalent Length (l)

Actual Length

Equivalent Length

Outdoor Unit Up

Outdoor Unit Down

P

ip

e

L

e

n

g

th

D

ro

p

H

e

ig

h

t

Piping

Outdoor Unit (one or more outdoor units)

Indoor Unit

Indoor Unit

In

do

or

U

nit

to

In

do

or

U

nit

D

ro

p

He

igh

t

Max Piping Equivalent Length L 125m

(From the first branch) Max piping Equivalent Length l 40m

Branch header

D

ro

p

H

ei

gh

t b

et

w

ee

n

In

do

or

un

it

an

d

ou

td

oo

r

U

ni

t

H

50

m

First branch

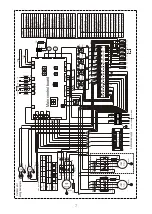

Make sure there is no any dirt or water before

connecting the piping to the outdoor units.

Wash the piping with high pressure nitrogen, never

use refrigerant of the outdoor unit.

Remove Dirt or Water in the Piping

Airtight Test

1. Connect piping on hi-pressure side with hi-pressure

valve. (For multi-modules parallel connection, please

connect gas and oil balance valves.)

2. Weld the piping on low-pressure side with gauge joint.

3. Charge nitrogen from hi-pressure valve core and gauge

joint.

4. After airtight test, weld low-pressure ball valve and

piping on low--pressure side.

CAUTION

2

1. Pressured nitrogen [2.94MPa (30kg/cm ) should be used in the

airtight test.

3. The airtight test should never use any oxygen, flammable gas

or poisonous gas.

2. Do not connect piping on low-pressure side and low-pressure ball

valve before charging nitrogen.

4. Wrap low-pressure valve and balance valves with wet cloth while welding.

Hi-pressure valve

Low-pressure ball valve

Gauge joint

Do vacuum with vacuum pump instead of refrigerant.

Vacuum with vacuum pump

Vacuuming should be done from liquid and gas side

simultaneously. The pressure should be lower than

30Pa.

Open all valves

Refrigerant Amount to be Added

Calculate the added refrigerant according to the diameter

and the length of the liquid side pipe of the ou tdoor/indoor

unit connection. The refrigerant is R22.

Pipe size on liquid side

Refrigerant to be Added per meter

Oil balance valve

Gas balance valve

Gas balance valve

Indoor unit and branch joint

Summary of Contents for MDV-D Series

Page 12: ......