b.

Using wire strippers, strip the rubber jacket

from both ends of the signal cable to reveal

approximately 15cm (5.9”) of wire.

c.

Strip the insulation from the ends.

d.

Using a wire crimper, crimp u-lugs on the

ends.

NOTE:

When connecting the wires, strictly

follow the wiring diagram found inside the

electrical box cover.

2.

Remove the electric cover of the outdoor unit.

If there is no cover on the outdoor unit, take

off the bolts from the maintenance board and

remove the protection board.

(See Fig. 8.1, 8.2)

Cover

Screw

Fig. 8.1

Protection Board

Fig. 8.2

3.

Connect the u-lugs to the terminals

Match the wire colors/labels with the labels

on the terminal block, Firmly screw the u-lug

of each wire to its corresponding terminal.

4. Clamp down the cable with the cable clamp.

5.

Insulate unused wires with electrical tape.

Keep them away from any electrical or metal

parts.

6.

Reinstall the cover of the electric control box.

Indoor Unit Wiring

1.

Prepare the cable for connection

a. Using wire strippers, strip the rubber jacket

from both ends of the signal cable to reveal

about 15cm (5.9”) of the wire.

b.

Strip the insulation from the ends of the

wires.

c.

Using a wire crimper, crimp the u-lugs to

the ends of the wires.

Page 21

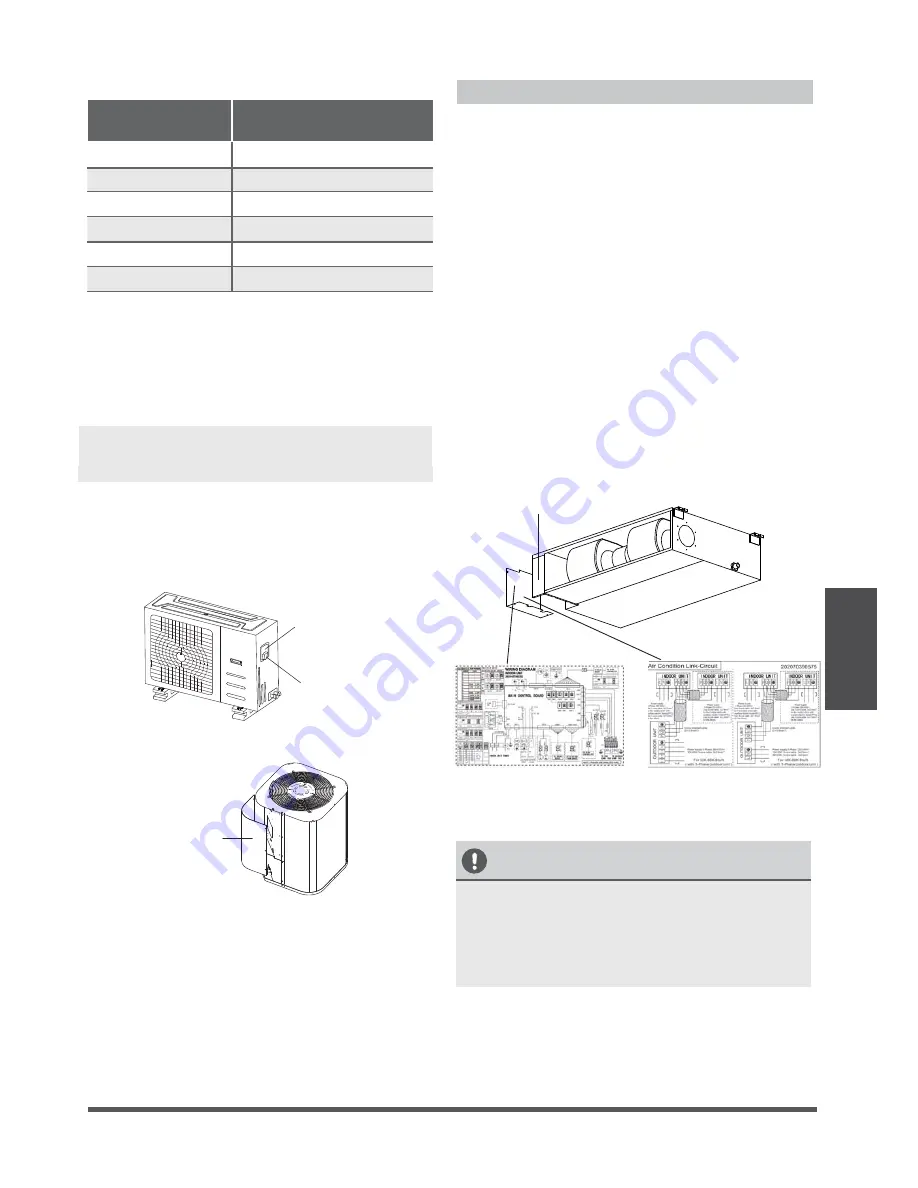

Wiring

2.

Remove the cover of the electric control box

on your indoor unit.

3.

Connect the u-lugs to the terminals.

Match the wire colors/labels with the labels

on the terminal block, Firmly screw the u-lug

of each wire to its corresponding terminal.

Refer to the Serial Number and Wiring

Diagram located on the cover of the electric

control box.

Connective wiring diagram

Wiring diagram

Control box

CAUTION

•

While connecting the wires, please strictly

follow the wiring diagram.

•

The refrigerant circuit can become very

hot. Keep the interconnection cable away

from the copper tube.

4.

Clamp down the cable with the cable clamp.

The cable must not be loose or pull on the

u-lugs.

5.

Reattach the electric box cover.

Fig. 8.3

Table 8.2: Other World Regions

Rated Current of

Appliance (A)

Area (mm²)

Nominal Cross-Sectional

6

0.75

6 - 10

1

10 - 16

1.5

16 - 25

2.5

25- 32

4

32 - 45

6

Summary of Contents for MEHSU-12CHD2

Page 30: ...Test Run Page 30...