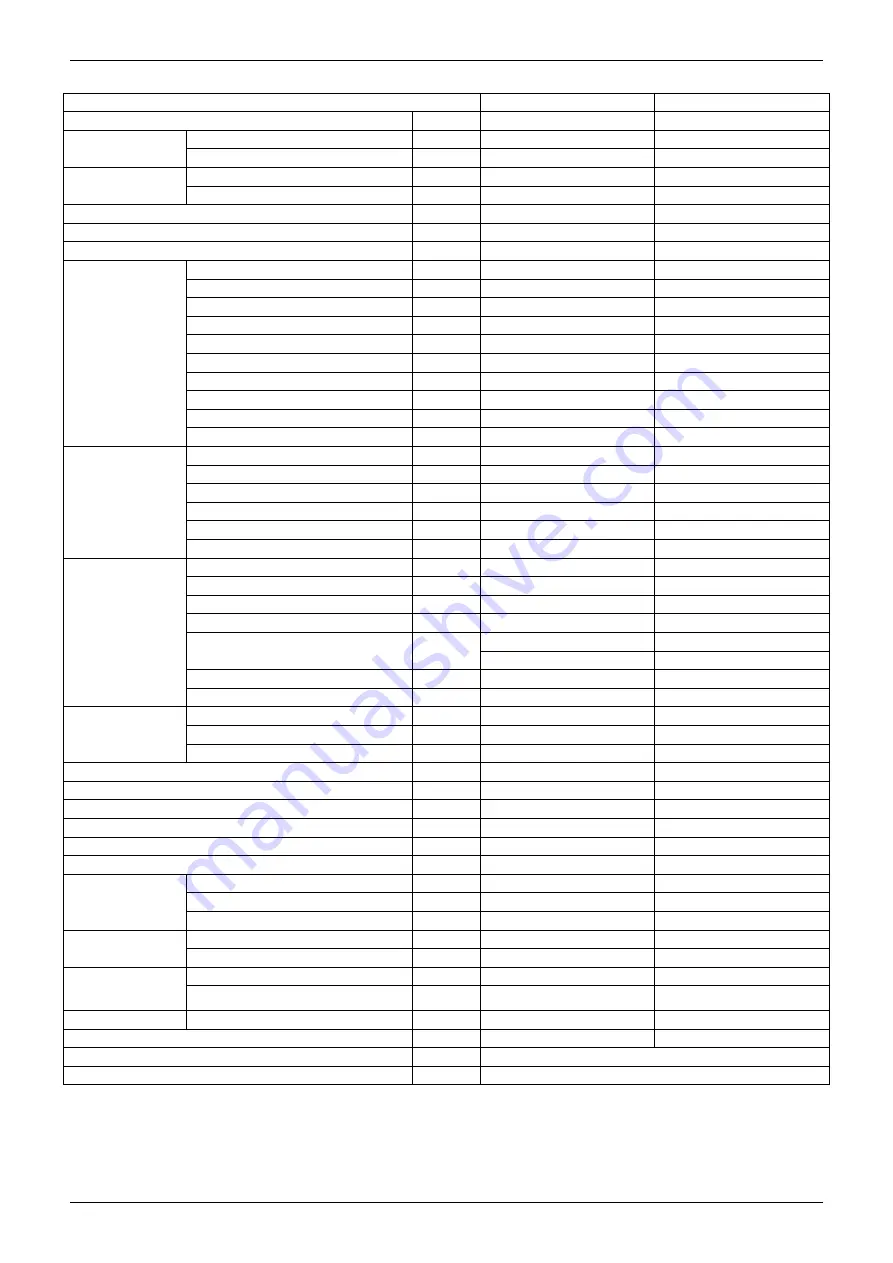

Specification

MCAC-TSM-2008-02

10

Installation

Model MGC-F10W/SN1 MGC-F12W/SN1

Power supply

V-Ph-Hz

380-415 , 3, 50

380-415 , 3, 50

Capacity kW

10.5 12

Cooling

Input W

3930 4410

Capacity kW

12 14

Heating

Input W

4240 4643

Max. input consumption

W

4400 5000

Max. input current

A

8.3 9.1

Starting current

A

45 66

Model

ZP50K3E-TFD-522 C-SBN373H8D

Type

SCROLL SCROLL

Brand

Copeland SANYO

Capacity Btu/h

42300 48109.2

Input W

4100 4750

Rated current (RLA)

A

7.3 8.22

Locked rotor Amp (LRA)

A

64 66

Thermal protector

Inner Inner

Capacitor uF

/ /

Compressor

Refrigerant oil

ml

POE OIL

,

1952 FV68S,

1700

Model

YDK100-6A(×2)

YDK100-6A(×2)

Type

AC motor

AC motor

Brand

Welling Welling

Input (Hi/Lo)

W

185/120 185/120

Capacitor uF

5uF/450V 5uF/450V

Outdoor fan

motor

Speed (Hi/Lo)

r/min

860/610 860/610

Number of rows

2 2

Tube pitch(a)× row pitch(b)

mm

22×19.05 22×19.05

Fin spacing

mm

1.5 1.5

Fin type

Hydrophilic aluminium foil

Hydrophilic aluminium foil

φ

7.94

φ

7.94

Tube outside dia. and type

mm

Inner grooved copper tube Inner grooved copper tube

Coil length ×height × width

mm

807×1188×38.1 945×1188×38.1

Outdoor coil

Number of circuits

7 7

Type

RL25/8.5 RL25/8.5

Input (H/M/L)

W

210/175/120 210/175/120

Water pump

Outdoor air flow

m

3

/h

6465/4270 6470/4280

Throttle

Capillary Capillary

Outdoor noise level (sound pressure)

dB(A)

58/48 59/49

Water flow volume m

3

/h

1.72 2.0

The plate heat-exchanger water pressure drop

kpa

44 40

The Max. and Min. water inlet pressure

kpa

500/150 500/150

Dimension (W×H×D)

mm

940×1245×360 1070×1249×420

Packing (W×H×D)

mm

1058×1380×438

1188×1385×498

Outdoor unit

Net/ Gross weight

kg

131/139

137/145

Type

R410A

R410A

Refrigerant

type/Quantity

Charged volume

g

2700

3000

Power wiring

mm

2

5×2.5 5×2.5

Connection

wiring

Signal wiring (connect to wired

control)

mm

2

3×1.0 3×1.0

Pipe diameter

Water inlet/outlet

mm

R5/4 R5/4

Control

Wired controller

Wired controller

Ambient temp

.

℃

Cooling: 10

℃

~43

℃

; Heating: -15-24

℃

Nominal capacity is based on the following conditions:

1. Condenser air in 35

℃

. Evaporator water in/out 12/7

℃

2. Evaporator air in 7

℃

85% R.H., Condenser water in/out 40/45

℃

3. The two types of oil are equivalents

4. At 1m in open field fan side (sound pressure)

5. The maximum and minimum operating pressure values refer to the activation of the pressure switches

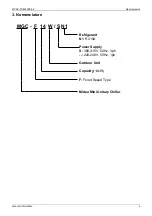

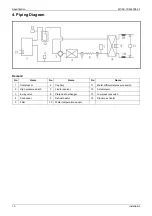

Summary of Contents for MGC-F05W/N1

Page 2: ......

Page 15: ...MCAC TSM 2008 02 Outdoor units Outdoor units 13 2 2 MGC F09W N1 MGC F10W N1 MGC F10W SN1...

Page 16: ...Specification MCAC TSM 2008 02 14 Installation 2 3 MGC F12W SN1 MGC F14W SN1 MGC F16W SN1...

Page 19: ...MCAC TSM 2008 02 Outdoor units Outdoor units 17 5 Wiring Diagrams 5 1 MGC F05W N1 MGC F07W N1...

Page 20: ...Specification MCAC TSM 2008 02 18 Installation 5 2 MGC F09W N1 MGC F10W N1...

Page 39: ...MCAC TSM 2008 02 Outdoor units Outdoor units 37 8 Operation Limits...

Page 42: ...Specification MCAC TSM 2008 02 40 Installation 10 Exploded View 10 1 MGC F05W N1...

Page 44: ...Specification MCAC TSM 2008 02 42 Installation 10 2 MGC F07W N1...

Page 46: ...Specification MCAC TSM 2008 02 44 Installation 10 3 MGC F09W N1 MGC F10W N1...

Page 48: ...Specification MCAC TSM 2008 02 46 Installation 10 4 MGC F10W SN1...

Page 50: ...Specification MCAC TSM 2008 02 48 Installation 10 5 MGC F12W SN1 MGC F16W SN1...

Page 52: ...Specification MCAC TSM 2008 02 50 Installation 10 6 MGC F14W SN1...

Page 86: ...Standard Controller MCAC TSM 2008 02 84 Controller 3 Select the Clock CL...

Page 89: ...MCAC TSM 2008 02 Standard Controller Controller 87...

Page 94: ...Standard Controller MCAC TSM 2008 02 92 Controller...