MCAC-TSM-2008-02

Description of Standard Unit

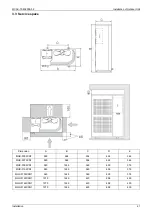

Installation

65

2. Description of Standard Unit

These air cooled reverse-cycle chillers with axial-flow fans operate with refrigerant fluid and are suitable for

outdoor installation.

They are factory tested and on site installation is limited to water and electrical connections.

Structure:

Panels and base are made from galvanized steel plate painted with epoxy powder to ensure total resistance

to atmospheric agents. Condensate collection pan as standard.

Compressors:

Scroll compressor with crankcase heater and thermal cut-out.

Evaporator:

AISI 316 stainless steel plate type evaporator complete with electric heater and differential pressure switch.

Casing lined with anti-condensate closed cell neoprene cladding.

Pump:

The units feature a pump with the moving parts in contact with the water made from corrosion resistant

materials, extra wear ring on the impeller, built-in capacitor for high starting torque and automatic venting of

impeller chamber.

Pump assembly:

Pump assembly with expansion tank, safety valve, auto water replenishing assembly, pressure gauge and

pump.

Condensing coil:

Made from copper tubes and high surface area aluminum fins. Condensing coil protection grills as standard.

Fans:

Axial-flow fans. Six-pole electric motor with built-in thermal cut-out. Housed in aerodynamic tubes with

accident prevention grill. Device for operation with low outside air temperatures: continuous fan rotation

speed control via condensing temperatures transducer.

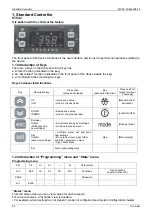

Power and control electrical panel

Power and control electrical panel constructed in accordance with IEC 204-1/EN60335-2-40, complete with

compressor contactor. Control via “HSW7” control panel.

Emergency stop push buttons

In case system crisis is occur (e. g: Compressor out of control ), press the emergency stop pushbuttons at

once, and turn it clockwise, until crisis is removed.

Optional accessories:

- Removable metal mesh filter.

- Remote keyboard kit.

- Additional pump.

The above accessories are optional. Consult the relative documentation for assembly instructions and

technical data.

Summary of Contents for MGC-F05W/N1

Page 2: ......

Page 15: ...MCAC TSM 2008 02 Outdoor units Outdoor units 13 2 2 MGC F09W N1 MGC F10W N1 MGC F10W SN1...

Page 16: ...Specification MCAC TSM 2008 02 14 Installation 2 3 MGC F12W SN1 MGC F14W SN1 MGC F16W SN1...

Page 19: ...MCAC TSM 2008 02 Outdoor units Outdoor units 17 5 Wiring Diagrams 5 1 MGC F05W N1 MGC F07W N1...

Page 20: ...Specification MCAC TSM 2008 02 18 Installation 5 2 MGC F09W N1 MGC F10W N1...

Page 39: ...MCAC TSM 2008 02 Outdoor units Outdoor units 37 8 Operation Limits...

Page 42: ...Specification MCAC TSM 2008 02 40 Installation 10 Exploded View 10 1 MGC F05W N1...

Page 44: ...Specification MCAC TSM 2008 02 42 Installation 10 2 MGC F07W N1...

Page 46: ...Specification MCAC TSM 2008 02 44 Installation 10 3 MGC F09W N1 MGC F10W N1...

Page 48: ...Specification MCAC TSM 2008 02 46 Installation 10 4 MGC F10W SN1...

Page 50: ...Specification MCAC TSM 2008 02 48 Installation 10 5 MGC F12W SN1 MGC F16W SN1...

Page 52: ...Specification MCAC TSM 2008 02 50 Installation 10 6 MGC F14W SN1...

Page 86: ...Standard Controller MCAC TSM 2008 02 84 Controller 3 Select the Clock CL...

Page 89: ...MCAC TSM 2008 02 Standard Controller Controller 87...

Page 94: ...Standard Controller MCAC TSM 2008 02 92 Controller...