MCAC-TSM-2008-02

Running and Maintenance

Installation

77

7.2 Routine maintenance

Never perform any cleaning operations before having disconnected the unit from the mains power supply.

Regular maintenance is fundamental to maintain the efficiency of the unit both in terms of operation and

energy consumption. The Technical Assistance Service maintenance plan must be observed, with an

annual service which includes the following operations and checks:

-

Filling of the water circuit

-

Presence of air bubbles in the water circuit

-

Efficiency of safety devices

-

Power supply voltage

- Power

input

- Tightness

of

electrical and hydraulic connections

-

Condition of the compressor contactor

-

Efficiency of the plate heat exchanger heater

-

Checking of operating pressure, superheating and sub cooling

-

Efficiency of compressor heater

-

Cleaning of finned coil (*)

-

Cleaning of fan grills

-

Cleaning of condensate drain pan.

(*) For

“

Heat pump

”

appliances, the checks are to be performed quarterly.

For units installed near the sea, the intervals between maintenance should be halved.

7.3 Extraordinary maintenance

Chemical washing

Chemically wash the plate heat exchanger after every 3 years of operation.

Refrigerant gas content

The chillers are filled with R410a refrigerant gas and tested in the factory. In normal conditions, there should

be no need for the Technical Assistance Service to intervene to check the refrigerant gas. However, over

time, small leaks may develop at the joints leading to loss of refrigerant and draining of the circuit, causing

the unit to function poorly. In this case, the leaks of refrigerant must be identified and repaired and the

refrigerant circuit refilled. Proceed as follows:

-

Empty and dry the entire refrigerant circuit using a vacuum pump connected to the low and high

pressure tap until the vacuometer reads about 10Pa. Wait a couple of minutes and check that this value

does not rise to more than 200Pa

-

Connect the refrigerant gas cylinder or a filling cylinder to the low pressure line pressure gauge

connection.

-

Fill with the quantity of refrigerant gas indicated on the rating plate of the unit.

-

Always check the superheating and sub cooling values. In the nominal operating conditions for the

appliance, these should be between 5 and 10°C and between 4 and 8°C respectively.

-

After a couple of hours of operation, check that the liquid indicator indicates circuit dry (dry-green)

Important

In the event of partial leaks, the circuit must be completely emptied before being refilled

The R410a refrigerant must only be filled in the liquid state. Operating conditions other than nominal

conditions may produce considerably different values.

Seal testing or identification of leaks must only be carried out using R410a refrigerant gas, checking with a

suitable leak detector.

Summary of Contents for MGC-F05W/N1

Page 2: ......

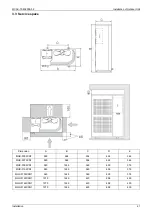

Page 15: ...MCAC TSM 2008 02 Outdoor units Outdoor units 13 2 2 MGC F09W N1 MGC F10W N1 MGC F10W SN1...

Page 16: ...Specification MCAC TSM 2008 02 14 Installation 2 3 MGC F12W SN1 MGC F14W SN1 MGC F16W SN1...

Page 19: ...MCAC TSM 2008 02 Outdoor units Outdoor units 17 5 Wiring Diagrams 5 1 MGC F05W N1 MGC F07W N1...

Page 20: ...Specification MCAC TSM 2008 02 18 Installation 5 2 MGC F09W N1 MGC F10W N1...

Page 39: ...MCAC TSM 2008 02 Outdoor units Outdoor units 37 8 Operation Limits...

Page 42: ...Specification MCAC TSM 2008 02 40 Installation 10 Exploded View 10 1 MGC F05W N1...

Page 44: ...Specification MCAC TSM 2008 02 42 Installation 10 2 MGC F07W N1...

Page 46: ...Specification MCAC TSM 2008 02 44 Installation 10 3 MGC F09W N1 MGC F10W N1...

Page 48: ...Specification MCAC TSM 2008 02 46 Installation 10 4 MGC F10W SN1...

Page 50: ...Specification MCAC TSM 2008 02 48 Installation 10 5 MGC F12W SN1 MGC F16W SN1...

Page 52: ...Specification MCAC TSM 2008 02 50 Installation 10 6 MGC F14W SN1...

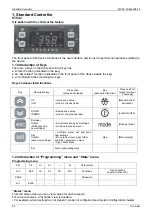

Page 86: ...Standard Controller MCAC TSM 2008 02 84 Controller 3 Select the Clock CL...

Page 89: ...MCAC TSM 2008 02 Standard Controller Controller 87...

Page 94: ...Standard Controller MCAC TSM 2008 02 92 Controller...