Aqua Mini Full DC Inverter Unitary Chiller 50Hz

86

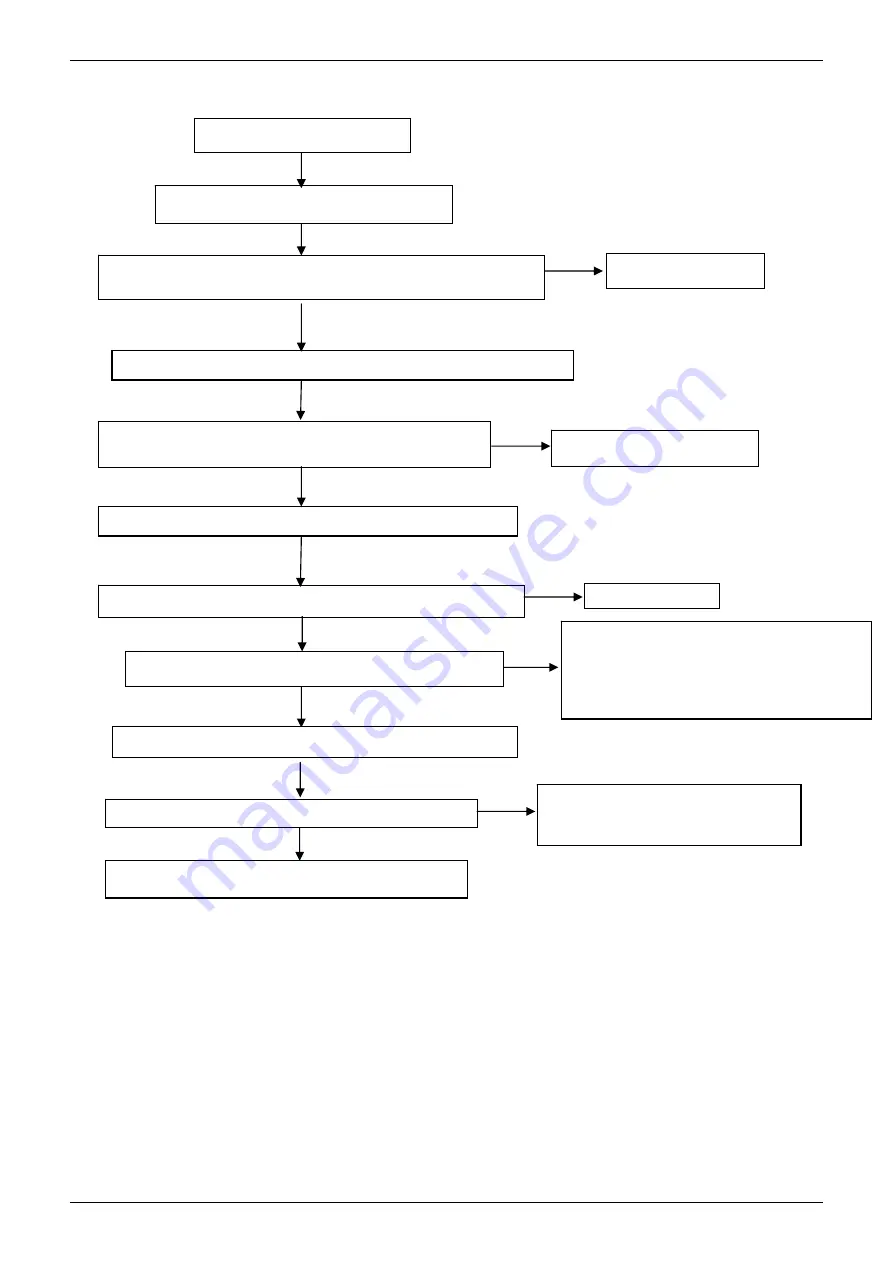

P2: Low pressure protection

LED displays P2

Low pressure protection

Whether wiring connection between low pressure switch and PCB is

connected well or properly.

Whether the low pressure switch is damaged.

Connect well again.

Short-circuit low pressure switch and check whether the

system can work normally.

Whether the cooling system can work as normal.

YES

NO

Check whether the outdoor ambient temperature is too low.

YES

Stop the unit.

NO

Whether refrigerant system leaks.

YES

Leakage detecting: add nitrogen or refrigerant

into the system. “si”,”si” will sound evidently if

leaks heavily. Use soap water(the combination

of water and detergent ) or electronic detector

to detect if leaks slightly.

Replace outdoor main PCB.

NO

NO

YES

Replace low pressure switch .

Connect pressure gauge with the system measuring port.

Replace the EXV, then use high

pressure nitrogen to clean and air the

pipeline, add the refrigerant at last.

Whether EXV works properly or stuck or blocked

YES

NO

NO

NO

Summary of Contents for MGRH10A-PA1Z

Page 16: ...Aqua Mini Full DC Inverter Unitary Chiller 50Hz 16 7 Wiring Diagram MGRH5A PA1Z MGRH7A PA1Z...

Page 17: ...Aqua Mini Full DC Inverter Unitary Chiller 50Hz 17 MGRH10A PA1Z...

Page 18: ...Aqua Mini Full DC Inverter Unitary Chiller 50Hz 18 MGRH12A PA3Z MGRH14A PA3Z MGRH16A PA3Z...

Page 29: ...Aqua Mini Full DC Inverter Unitary Chiller 50Hz 29 MGRH12A PA3Z MGRH14A PA3Z...

Page 30: ...Aqua Mini Full DC Inverter Unitary Chiller 50Hz 30 MGRH16A PA3Z...

Page 32: ...Aqua Mini Full DC Inverter Unitary Chiller 50Hz 32 13 Exploded View MGRH5A PA1Z MGRH7A PA1Z...

Page 34: ...Aqua Mini Full DC Inverter Unitary Chiller 50Hz 34 MGRH10A PA1Z...

Page 36: ...Aqua Mini Full DC Inverter Unitary Chiller 50Hz 36 MGRH12A PA3Z MGRH14A PA3Z MGRH16A PA3Z...