MCAC-UTSM-201406 Midea R410A Full DC Inverter Split Type Series Technical Manual

64

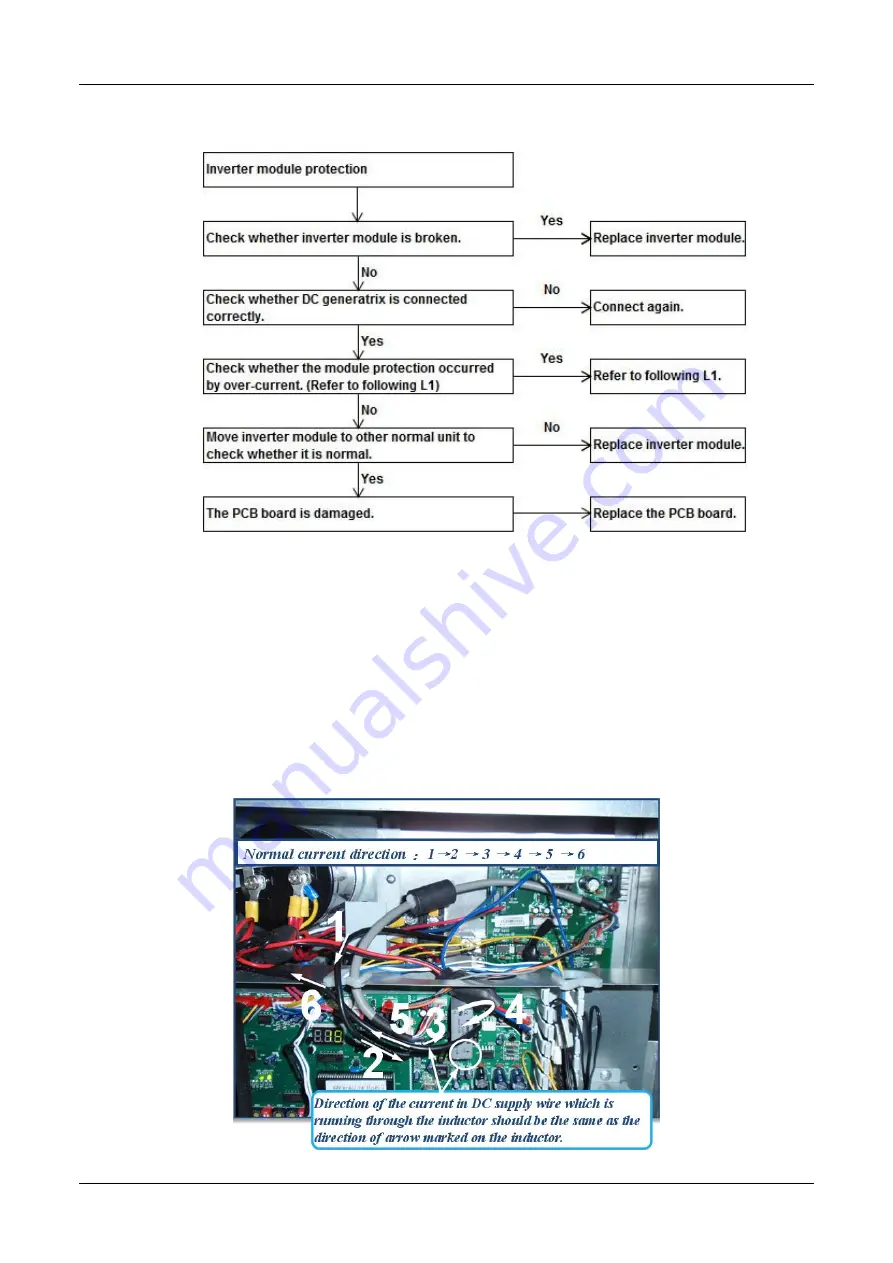

P6: Inverter module protection

Notes:

There are three times in 30 minutes,

‘H4’ will be displayed. Repower-on, the protection will be

canceled. At the same time, the reason of protection should be settled.

P6 will be displayed only one minute. After P6 disappears, the specific error code will be displayed

by pressing check button. The specific error is include L0, L1, L2, L4, L5, etc.

DC generatrix check