Maintenance and

Disassembly

Page 23

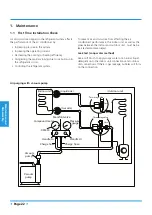

Procedure:

1.

Tighten the flare nuts of the indoor and outdoor

units, and confirm that both the 2- and 3-way valves

are closed.

2.

Connect the charge hose with the push pin of Handle

Lo to the gas service port of the 3-way valve.

3.

Connect another charge hose to the vacuum pump.

4.

Fully open the Handle Lo manifold valve.

5.

Using the vacuum pump, evacuate the system for

30 minutes.

a.

Check whether the compound meter indicates

-0.1 MPa (14.5 Psi).

• If the meter does not indicate -0.1 MPa

(14.5 Psi) after 30 minutes, continue

evacuating for an additional 20 minutes.

• If the pressure does not achieve -0.1 MPa

(14.5 Psi) after 50 minutes, check for leakage.

• If the pressure successfully reaches -0.1 MPa

(14.5 Psi), fully close the Handle Lo valve, then

cease vacuum pump operations.

b.

Wait for 5 minutes then check whether the gauge

needle moves after turning off the vacuum pump.

If the gauge needle moves backwards, check

whether there is gas leakage.

6.

Loosen the flare nut of the 3-way valve for 6 or

7 seconds and then tighten the flare nut again.

a.

Confirm the pressure display in the pressure

indicator is slightly higher than the atmospheric

pressure.

b.

Remove the charge hose from the 3-way valve.

7.

Fully open the 2- and 3-way valves and tighten the

cap of the 2- and 3-way valve.

Summary of Contents for MISSION2 3D INVERTER Series

Page 2: ......

Page 4: ......

Page 11: ...Specifications Page 7 MOB01 09HFN1 MW0W MOB01 12HFN1 MV0W MOCA01 18HFN1 MT0W...

Page 12: ...Specifications Page 8 MOD01 23HFN1 MT0W...

Page 15: ...Specifications Page 11 PCB board of MOD01 23HFN1 MT0W...

Page 16: ...Specifications Page 12 IPM board of MOD01 23HFN1 MT0W...