40

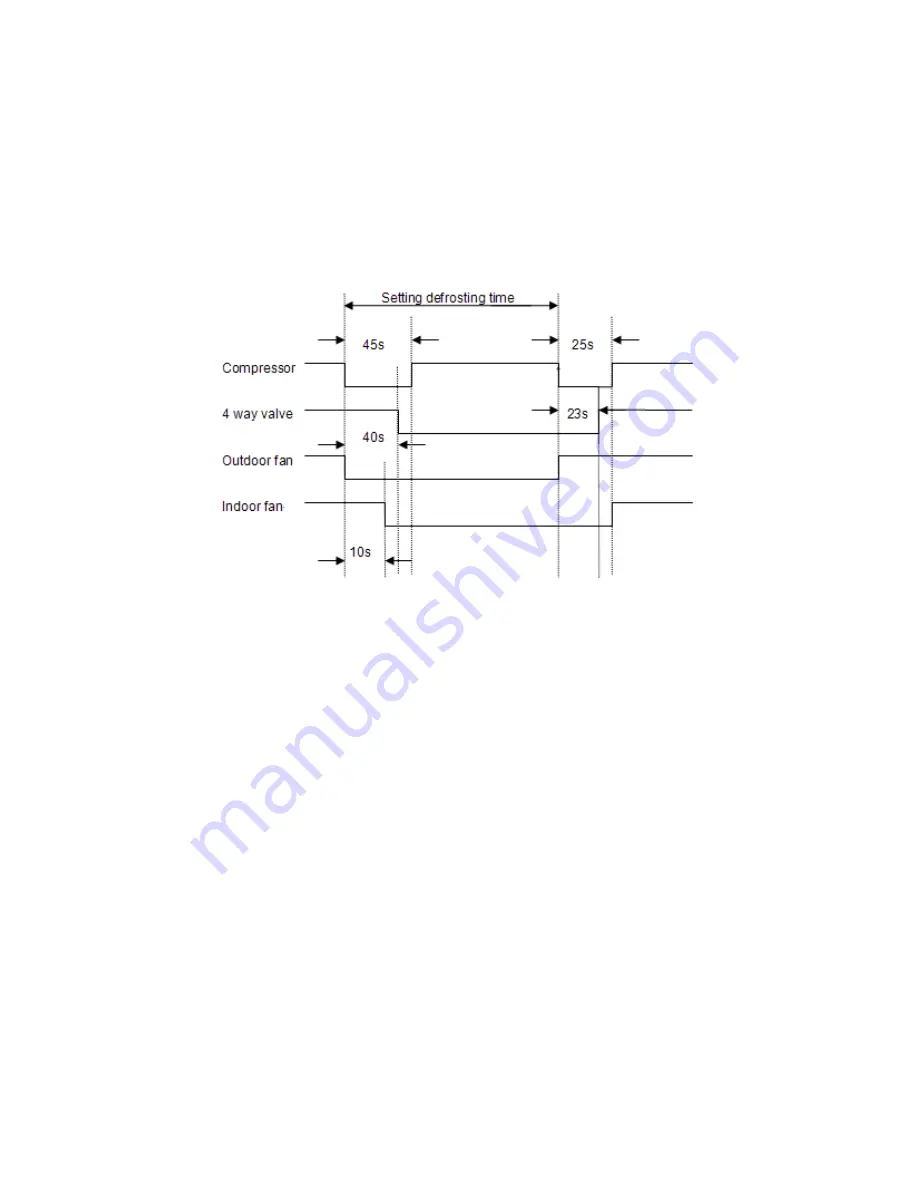

Condition of ending defrosting:

If any one of the following items is satisfied, the defrosting will terminate and the machine will turn to

normal heating mode.

(1) The defrosting time is reached to the setting value.

(2) The compressor current has reached or exceeded I

DEFROST

for 7 seconds.

Defrosting action

:

About the setting defrosting time:

(1) Condition 1 of defrosting;

If case B happens before case A and lasts till case A happens, the setting defrosting time is 10 minutes.

Otherwise the defrosting time is 7.5 minutes.

(2) Condition 2 of defrosting.

The defrosting time is 10 minutes.

(3) No matter what condition of the defrosting is, if the defrosting time keeps 7.5 minutes for 3 times, it

will be 10 minutes in the 4

th

defrosting.

Summary of Contents for MOA-11HN1-QB8

Page 1: ...LUNA ON OFF SERIES Service Manual 2014 9ASEU B1 1401...

Page 16: ...14 MS9A 12HRN1 QC7G...

Page 17: ...15 MS9A 18HRN1 QC5...

Page 18: ...16 MS9A 24HRN1 QB8W...

Page 20: ...18 MOC 17HN1 QC0...

Page 21: ...19 MOC 18HN1 QC0 MOF3 18HN1 QC5...

Page 22: ...20 MOP 24HN1 QB8W...

Page 23: ...21 MOF1 24HN1 QB8W...