Summary of Contents for MOAB01-07HN1

Page 12: ...Mission On off DM16 01 01 21en 12 Service manual For MSMBA 07HRN1 W MSMBA 09HRN1 W...

Page 13: ...DM16 01 01 21en Mission On off Service manual 13 For MSMBB 12HRN1 W For MSMBC 19HRN1 W...

Page 14: ...Mission On off DM16 01 01 21en 14 Service manual For MSMBD 24HRN1 W...

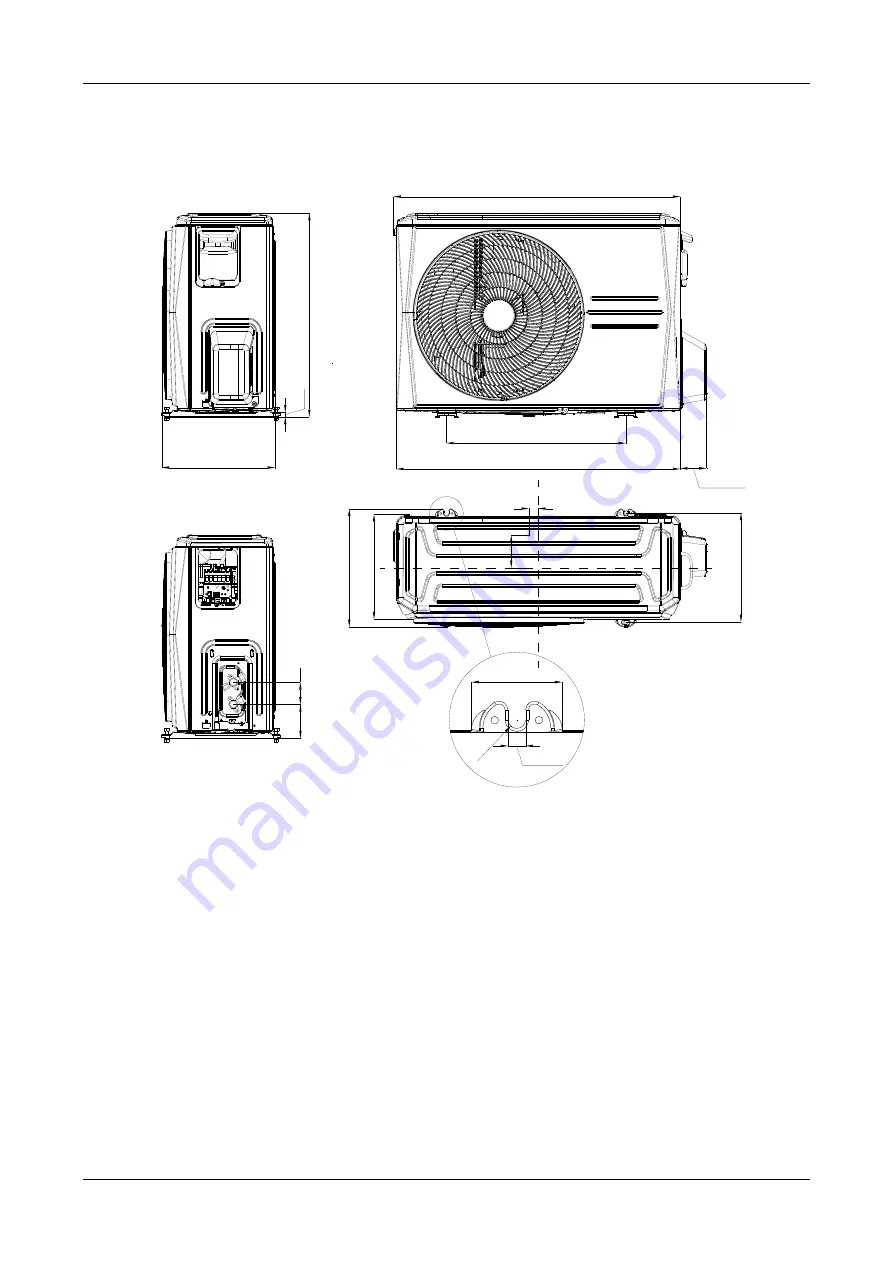

Page 16: ...Mission On off DM16 01 01 21en 16 Service manual For MOAB01 07HN1 MOAB01 09HN1...

Page 18: ...Mission On off DM16 01 01 21en 18 Service manual For MOCA01 24HN1...