1.4 FEATURES

All the models have two types of the cover and panel

structure.

No need for special installation. Four casters on the

bottom for easy movement and simple and convenient

use.

Only one exhaust pipe, and easier to use.

Remote-controlled or gentle-touch keys for easy and

comfortable use.

Compressors of famous brands are adopted for reliability

and low noise.

Multiple uses: dehumidifying and cloth drying.

The heating system uses PTC electrical heater and will not

be affected by ambient temperature, which saves energy.

Suitable for local cooling and heating.

Large volume tank, and convenient to use.

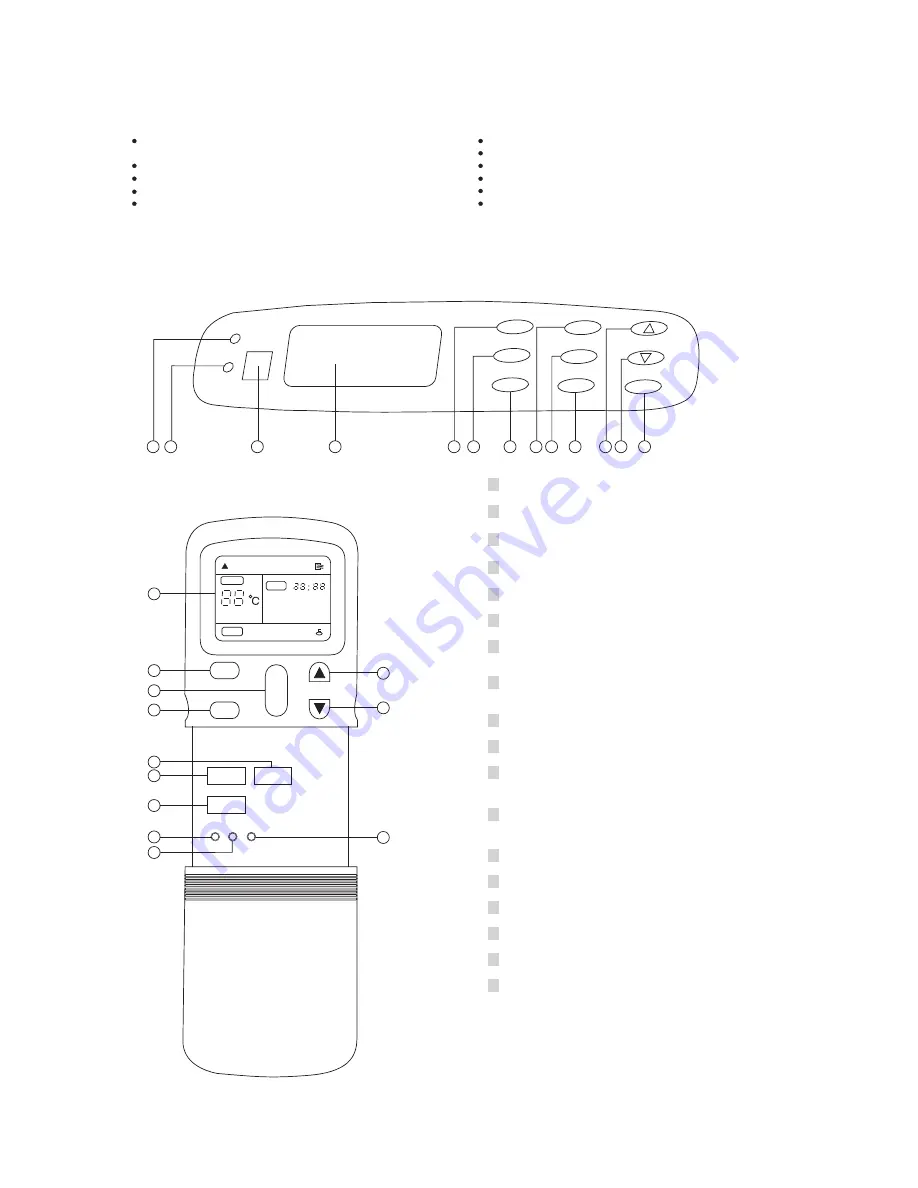

1.5 DISPLAY PANEL AND REMOTE CONTROL

DISPLAY PANEL

1

5

4

3

2

1

Signal receiver

2

Heat/cool/dry lamp

3

Water full lamp

4

Operation display

5

1/0 button

AUTO COOL DRY HEAT FAN

TEMP

CLOCK

SPEED

AUTO LOW MED HIGH

MODE

1/0

TEMP/TIMER

FAN

SWING

CLOCK

SET

REMOTE CONTROL

6

8

5

6

7

D

E

F

G

H

A

9

I

6

Remote display

7

Mode button

8

9

Fan button

A

B

C

Swing button

D

Up button

E

Clock button

F

Reset button

G

Lock button

H

I

Timer on button

Timer off button

Display the situation of operation setting.

Select the operation mode, AUTO, COOL, DRY, HEAT

and FAN.

Press this button to operation the unit, again to stop.

Select the Fan speed, AUTO, LOW, MED, HIGH.

Press this button to activate the auto swing, again to

stop.

Press this button to increase the setting temperature

or Timer time.

Press this button to activate the time setting.

Press this button to reset all settings to original.

Press this button to lock all button except this button.

Press this button to activating TIMER ON time setting.

Press this button to activating TIMER OFF time setting.

WATER FULL

HEAT

COOL

DRY

1/0

FAN

SWING

MODE

ON

TIMER

OFF

CLOCK

TEMP./CLOCK

AD .

J

L R

O

o

C/ F

7

8

9

A

B C

D

Down button

Press this button to decrease the setting temperature

or Timer time.

Set button

Press this button to activate the Time ON/OFF setting.

O

o

C/ F button

Press this button to select temperature settings in

either Celsius or Farenheight .

`

`

`

`

`

`

`

`

4