Bar

Copper pipe

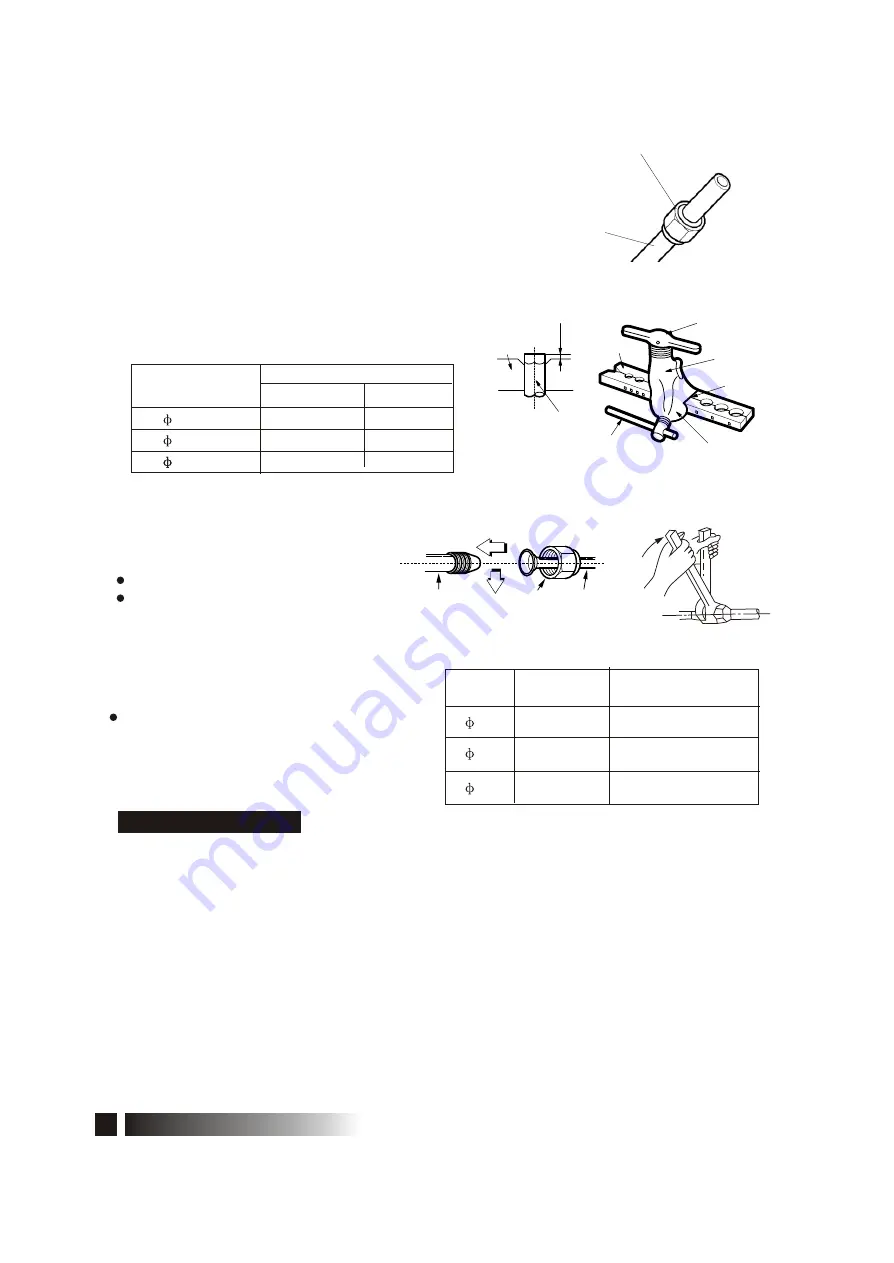

Clamp handle

Red arrow mark

Cone

Yoke

Handle

Bar

"A

"

C: Putting nut on

Remove flare nuts attached to indoor and

outdoor unit, then put them on pipe/tube

having completed burr removal.(not possible

to put them on after flaring work)

Flare nut

Copper tube

Fig.16

Fig.17

D: Flaring work

Firmly hold copper pipe in a die in the

dimension shown in the table below.

CAUTION

Align the center of the pipes..

Sufficiently tighten the flare

nut with fingers, and then tighten

it with a spanner and torque wrench

as shown.

Tightening Connection

Excessive torque can break nut

depending on installation conditions.

Outer

diam.

Tightening

torque(N.cm)

Additional tightening

torque(N.cm)

6.35

1570

(160kgf.cm)

1960

(200kgf.cm)

4900

(500kgf.cm)

5390

(550kgf.cm)

12.7

Outer diam.

(mm)

A(mm)

Max.

Min.

6.35

1.3

0.7

9.53

1.6

1.0

12.7

1.8

1.0

9.53

2940

(300kgf.cm)

3430

(350kgf.cm)

Fig.19

Indoor unit tubing

Flare nut

Pipings

Fig.18

ELECTRICAL WORK

Electric safety regulations for the initial Installation

1. If there is serious safety problem about the power supply, the technicians should refuse

to install the air conditioner and explain to the client until the problem is solved.

2. Power voltage should be in the range of 90%~110%of rated voltage.

3. The creepage protector and main power switch with a 1.5 times capacity of Max. Current

of the unit should be installed in power circuit.

4. Ensure the air conditioner is grounded well.

7. An individual branch circuit and single receptacle used only for this air conditioner must be

available. See the following table for suggested wire sizes and fuse specifications:

5. According to the attached Electrical Connection Diagram located on the panel of the outdoor

unit to connect the wire.

6. All wiring must comply with local and national electrical codes and be installed

by qualified and skilled electricians.

9

Electrical work

12.7

1.8

1.0

Summary of Contents for MSH-18HRIN1

Page 15: ...CS309 I 2200019589 ...