V6-i VRF 50/60Hz

75

P

art

6

- Di

agno

si

s and

Tr

ou

bles

ho

o

ting

Procedure

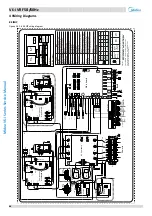

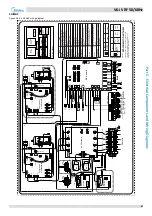

2.3.5

E2

Communication wires P Q E have short

circuited or disconnected

1

Yes

Reconnect the communication wires

No

Communication wires P Q E are not

connected in a daisy chain

Yes

Connect the communication wires in a

daisy chain

No

IDU power supply is abnormal

Yes

Ensure normal power supply

No

Wires between outdoor main PCB and

electric control box communication

terminals block are loose

Yes

Ensure the wires are connected properly

No

Interference from high voltage (220V or

higher) wires

Yes

Ensure the communication wires and

high voltage wires are separated

No

Communication wires are close to a

source of electromagnetic radiation such

as transformer or strong fluorescent lamp

Yes

Remove the source of interference, or

add additional shielding to the

communication wires

No

The length of communication wire is over

1200m

Yes

Reduce the wire length to less than

1200m or strengthen the signal

No

Replacing outdoor main PCB resolves the

error

No

Replace electric control box

communication terminals block

Notes:

1.

Measure the resistance among P, Q and E. The normal resistance between P and Q is 120Ω, between P and E is infinite, between Q and E is infinite.