!

!

CAUTION

CAUTION

VENT DOOR FILTER

I

MPORTANT:TURN UNIT OFF BEFORE

UNIT DAMAGE HAZARD

Failure to follow this caution may result in

equipment damge or improper operation.

Airflow restriction may cause damage to the unit.

- The most important thing you can do to maintain

unit efficiency is to clean the filters once every

two weeks as required.

Clogged filters reduce cooling, heating and airflow.

UNIT DAMAGE HAZARD

Failure to follow this caution may result in equipment

damage or improper operation.

· Do not operate unit without filters in place. If a filter

becomes torn or damaged, it should be replaced

immediately.

· Operating without filters in place or with damaged

filter will allow dirt and dust to reach indoor coil and

reduce cooling ,heating, airflow and efficiency of unit.

CLEANING.

- If the vent door is open, access requires the removal of

the unit from the wall sleeve. Clean the vent filter twice a

year or as required.

- Make sure to remove the shipping screw from the vent

door.(See.Fig.5)

- Rotate the vent control lever to open the vent door.

(See. Fig.6)

- Remove four screws from the vent door filter.

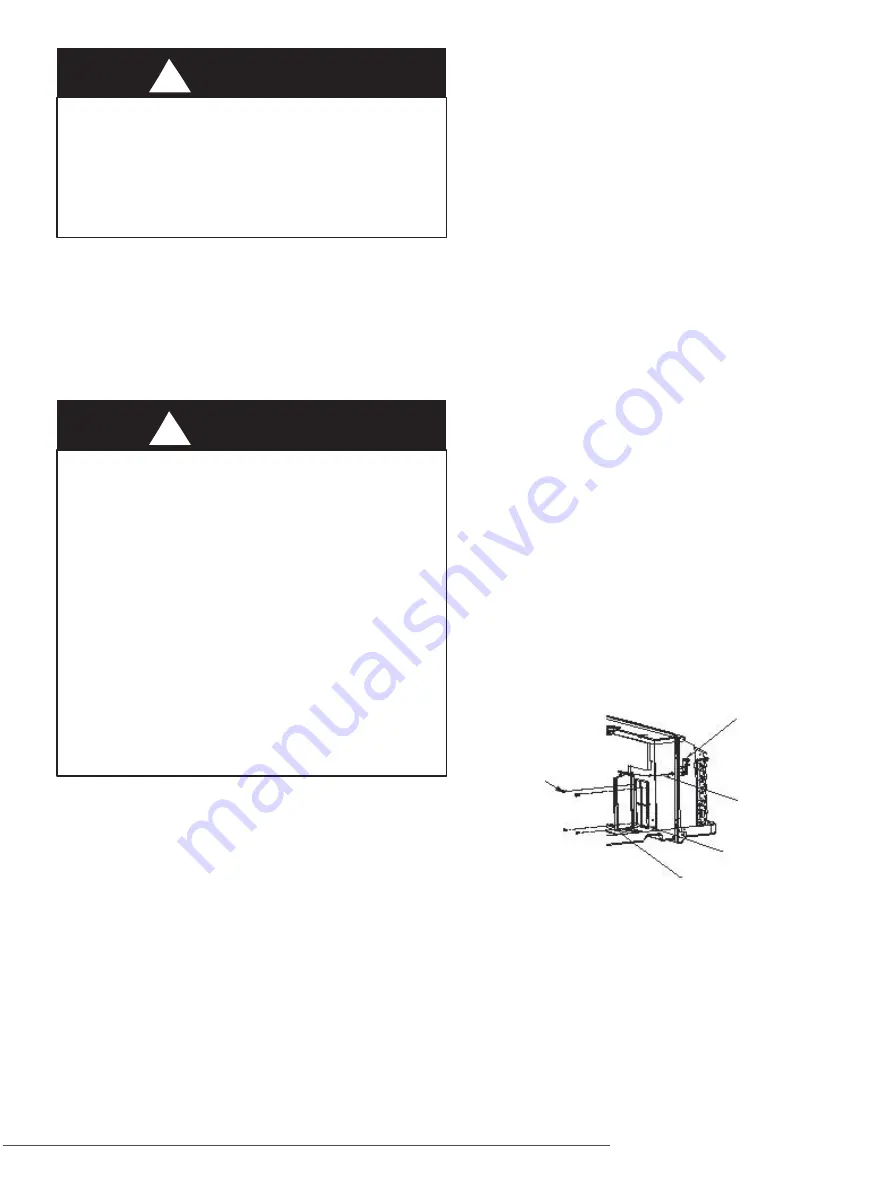

(See.Fig.12)

- First pull out the vent door steel wire from the hole of

the vent door, then take off the vent door and filter.

(See.Fig.12)

- Clean the filter. Dry thoroughly before placing.

- Replace the vent door and filter, reinstall the four

screws.

- Reinsert the vent door steel wire into the hole of the

vent door.

Vent door

control lever

Airflow restriction may cause damage to unit.

-

The most important thing you can do to maintain

unit efficiency is to clean the filters once every

two weeks as required.

Clogged filters reduce cooling, heating and airflow.

-

Keeping filters clean will:

Screws

Fig.12

Vent door

steel wire

Vent door

filter

Vent door

Decrease cost of operation.

Save energy.

Prevent clogged indoor coil.

Reduce risk of premature component failure.

- To Clean Air Filters:

Vacuum off heavy soil.

Run water through filter.

Dry thoroughly before replacing.

www.mideaaircon.com

20