3. 3 Operation Modes and Functions

The compressor and outdoor fan are OFF at Fan-only mode

(except P1 protection).

The speed of indoor fan can be optionally chosen as High/Mid/Low.

The TS can’t be controlled because of the LED displaying as T1.

The ION/TIMER functions are valid at the fan-only mode.

3.3.2 Fan-only mode function requirement

3.3.3 Cooling mode function requirement

3.3.1 Auto mode function requirement

TS range is 62

℉

~88

℉

(

17

℃

~30

℃).

When T1<TS-1, select the setting temperature of TS-1

for Heating operation’s temperature.

When TS+2

≥

T1

≥

TS-1,select the Fan-only mode.

When T1>TS+2, select the setting temperature(TS )

for Cooling operation’s temperature.

The indoor fan motor operates at Auto-fan mode with speed

uncontrolled and not changed.

The speed of indoor fan can be optionally selected as High/Mid/Low.

The outdoor fan will be turned on as soon as the unit being on cooling

mode.The operation of outdoor fan is according to the compare of

T1 and TS when the water level is below to switch 1.

If not, the outdoor fan doesn’t work.

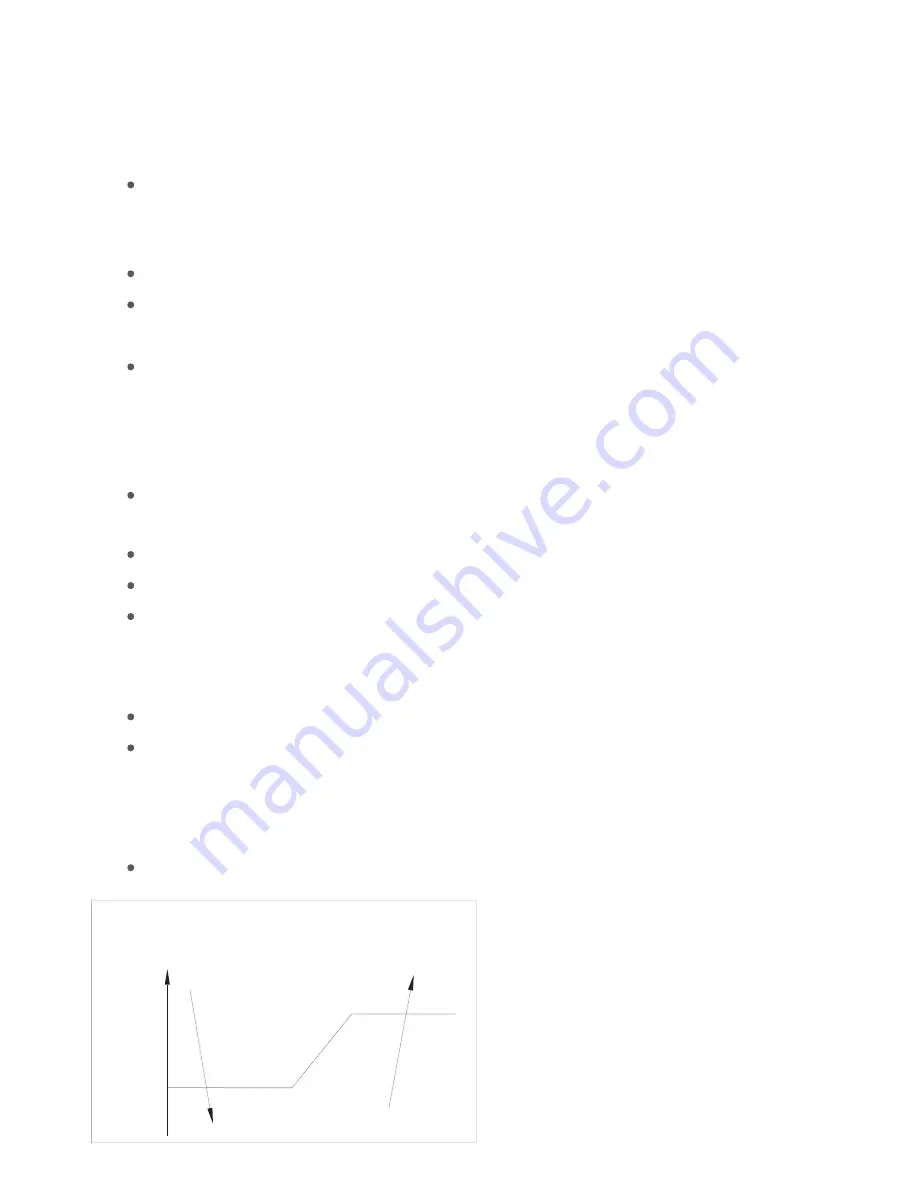

The compressor operates as below:

(T1-Ts)

℃

+1

0

Compressor on

Operation conditon

Compressor off

a) If T1

﹥

TS+1

℃

, outdoor fan

operates. After 15 seconds,

compressor operates.

b) The compressor is on, if T1

≤

TS,

this compressor will stop. If

outdoor fan operates for 3 minutes

at least, it will stop for a delay for 5

seconds.