Setting temperature

Adjust the button of temperature drop or rise on the control panel so that the display module will display

the appropriate temperature.

The display module displays the set temperature, and the temperature controlled range varies from 0 to

10

℃

(32-50

℉

).

The display module shows 5

℃

at the initial power. When pressing the button of temperature

rise or drop, the temperature will increase or decrease by 1

℃

(

℉

).

The optimal temperature of the storage and distribution of draft beer is 34 ~ 38

℉

(1.1 to 3.3

℃

).

Switch between Fahrenheit and Celsius temperature

The press of the "Fahrenheit / Celsius switch" key can realize the Fahrenheit and Celsius temperature switch.

The corresponding Fahrenheit or Celsius temperature value is displayed in the display module.

When the

“

Celsiustemperature

”

is selected, the lamp of

“℉”

When the

“

Fahrenheit temperature

”

is selected, the lamp of

“℃”

on the display module will be lightened

and the displayed value is Fahrenheit.

Quick cooling function

Press the

“

rapid cooling

”

key to enter the

“

quick cool

”

state. Lighten the

“

rapid cooling

”

icon on the

display module, and the temperature display"

“

00

”

. Repress the

“

rapid cooling

”

key to exit the state of

“

rapid cooling

”

and the icon goes off. The temperature shows entering into the setting state of pre-rapid

cooling.

Display function

In normal work, the display module will be lit instead of being closed.

Introduction to the beer machine's functions

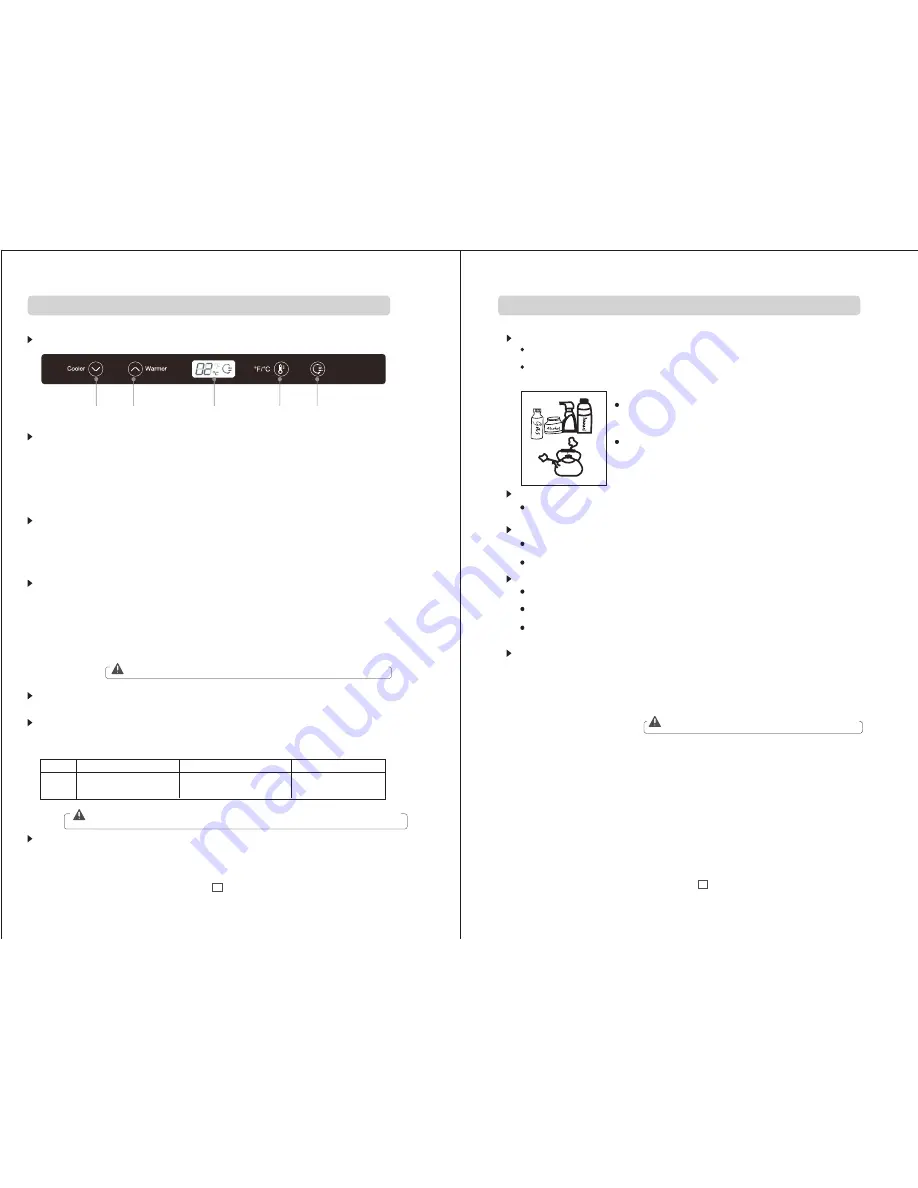

Operation panel

Temperature

drop

Temperature

rise

Display module

Fahrenheit/Celsius

switching

Rapid cooling

Fault prompt

When the following table prompts appear in the display module, it implies the failure of beer machine.

Although part of the fault condition occurs, the beer machine can still work. You should contact the

maintenance as soon as possible to achieve the optimization run of beer machine.

Prompt

E1

E4

E7

Fault

Temperature sensor failure

in the refrigerated zone

Ambient temperature

sensor fault

Defrosting sensor failure in

refrigerator compartment

Automatic defrosting

The beer machine doesn't need manual defrost. The frosting on the inner wall will automatically melt and

flow through the drainage holes to be automatically evaporated.

When two or more sensors fail simultaneously, all fault codes will display on the display module alternately.

If the ambient temperature sensor and refrigeration defrosting sensor fail, any key can be pressed. The temperature is

adjustable. The fault display will be restored after15 seconds later.

Rapid refrigeration function will be used only for the first barrel of beer in the box, desiring to use as

soon as possible when drinking. The normal use should not use this function to avoid ice beer.

After entering into

“

rapid cooling

”

state, the machine works 24Hcontinuously, and exits after 24H. At the

same time, rapid cooling icon is off. The temperature displays entering into the setting state of pre-rapid

cooling.

Deep Chill

Maintenance of the beer machine

Cleaning

Out of service

Transportation

If the machine is out of service more than three weeks, you should unplug the power and clean it

thoroughly. The beer machine should keep drying.

Fix the loose items in the beer machine with tape firmly; use the tape to fix the door of the machine to

avoid opening the door in transportation.

In transportation, loosen the trundles of the two foot brake, and the go on.

Do not use a hard brush, clean steel ball, wire brushes, abrasives, such as

toothpaste, organic solvents (such as alcohol, acetone, bananas, water, etc.),

Water, the pH of the items to clean the beer machine.

Do not rinse with clean water so as not to affect the electrical insulation properties.

The interior of beer machine should be cleaned regularly. When cleaning, use a soft towel or sponge which is

dipped in water or non-corrosive neutral detergent. At end, wipe it with clean water and dry it with cloth. Open

the door to dry naturally before the power is turned on.

The dust of the back of beer machine and the ground needs cleaning up in time in order to improve the

cooling effect and help save energy at the same time.

Warm prompt

Beer machine is mainly used for storage of bottled beer and other items. Please increase the set temperature

(greater than or equal to 5

℃

) to avoid the inside temperature too low.

;

If there is sound of air or hum when the machine is in use, the noise is caused by the refrigerant flowing in the

cooling pipe and running in the compressor, which is normal phenomenon.

;

The beer machine has no heating function. When the set temperature is higher than the ambient temperature,

the machine will not run.

The use of specifications of beer kegs

Keg sizes that can be used in your beer dispenser.

1/2 barrel 59 Liters 15.5 gals. 1984 oz. 164 / 12-oz. Glass

1/4 barrel 30 Liters 7.8 gals. 992 oz. 82 / 12-oz. Glass

1/6 barrel 20 Liters 5.2 gals. 661 oz. 55 / 12-oz. Glass

1/8 barrel 15 Liters 4.0 gals. 496 oz. 41 / 12-oz. Glass

Our Beer dispenser accepts almost all Brand Name1/2 kegs.

However Coors' kegs do not fit in our unit.

4

5

Summary of Contents for WHS-209BESS1

Page 1: ...WHS 209BESS1...