A-1477/A-14167, Rev. 0

Page 23 of 37

Manual content is subject to change.

Visit midlandmfg.com for latest manual revision and revision history.

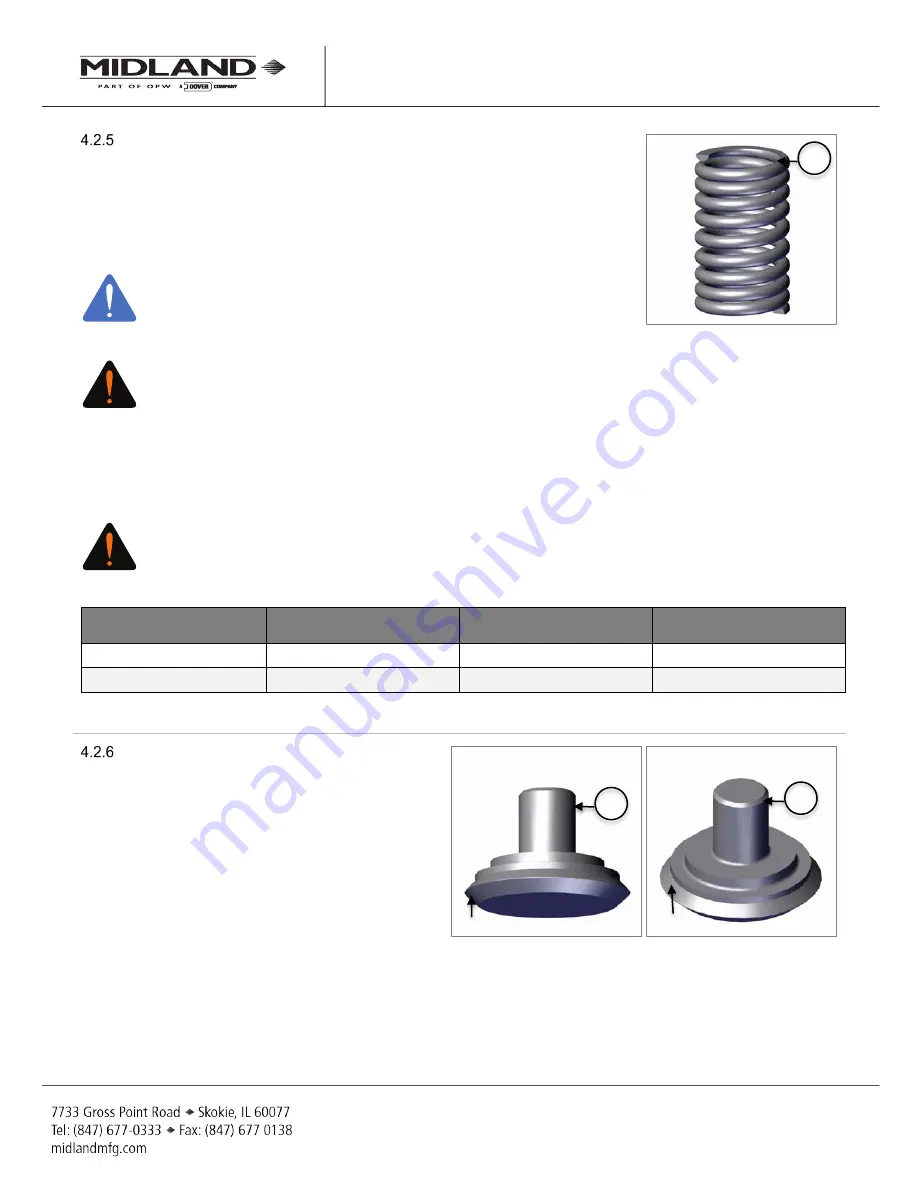

Spring Inspection

The spring (item 5) is a highly stressed part. The exterior surface must be

free of pitting, cracks and corrosion. If necessary, use magnetic-particle or

dye-penetration inspection (performed by certified and trained personnel) to

evaluate the exterior surface and ensure that it is free of cracks and corrosion

pits. If any excessive wear over 0.030” of the area is measured or observed,

the spring cannot be repaired and must be replaced.

NOTE:

Use of Enhanced Inspection Methods,

(LPI, MPI, etc.) is recommended.

Figure 4-22 Spring Inspection

WARNING: Valve-Spring Failure.

Defects in coil springs, such as cracks and corrosion pits, can act as

stress concentrators. Failure to detect these defects can result in coil-spring breakage and uncontrolled

valve venting.

Test the springs by pressing them to 80% of maximum deflection in a press for two (2) minutes. Remove from

the press and then measure the spring free-height. If free-height is less than the minimum indicated in Table 4-

2, replace the spring.

WARNING: Deficient Valve Travel.

Coil springs that have taken a “set,” resulting in an undersized free-

height, will not allow the valve to open fully. The spring should not be bowed more than 1/4" when in the

assembled position. Bowing in excess of this amount can cause the spring to rub against the inside wall

of the nozzle or guide tube and adversely affect the pressure settings. If any of the defects mentioned

above are observed, the spring cannot be repaired and must be replaced.

Spring Part Number

Wire Size (REF) (Inches)

Height at 80% of Max.

Deflection (Inches)

Minimum Free-Height

(Inches)

15-150-MO

0.28

2.8

4.00

15-225-SS

0.28

3.13

4.80

Table 4-2 Minimum Free-Heights for Spring After Pressing 80% of the Maximum Deflection for Two (2) Minutes

Plug Inspection

Visually inspect the plug (item 3) paying close

attention to sealing surfaces. It should be free

of corrosion, nicks, dents, scratches and pits.

Since the O-rings must seal against these

surfaces, any irregularities can cause the

valve to leak. Clean these areas by sanding

lightly with emery paper (400-grit). If this does

the effectively clean the part, replace this part.

The plug must be free of gouge marks,

corrosion, pits and rust. If present, this part is

rejectable and should be replaced.

The sealing surface is the crown of the seat.

Clean the seat with emery paper (400-grit)

then wipe it clean with a cloth and a suitable

solvent. Run your fingernail aroudn the surface

to detect any flaws. If any flaws are found, the

part is rejectable and should be replaced.

Figure 4-23 Plug Inspection

NOTICE

WARNING

WARNING

5

3

3

Seat Sealing Surface

O-Ring Sealing Surface