Installation

*INSTALLATION*

72

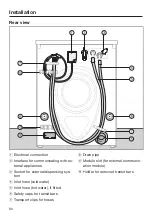

Electrical connection

This description applies to washing

machines both with and without a

mains plug.

The following applies to washing ma-

chines with a mains plug:

- The washing machine is ready to be

connected.

- The electrical socket must be easily

accessible after installation so that

the machine can be disconnected

from the electricity supply if neces-

sary.

Damage caused by incorrect

supply voltage.

The data plate indicates the nominal

power consumption and the appro-

priate fuse rating.

Compare the specifications on the

data plate with those of the mains

electricity supply and make sure that

they match.

The washing machine may only be con-

nected to a permanent electrical system

that conforms to the national and local

codes and regulations.

Do not connect the machine to an ex-

tension lead or multi-socket adapter as

they do not guarantee the required

safety of the appliance (e.g. danger of

overheating).

If the machine is hard wired, an all pole

circuit breaker must be provided on-

site. When switched off there must be

an all-pole contact gap of at least 3 mm

in the isolator switch (including mini-

ature circuit breaker, switch, fuses and

relays according to IEC/EN 60947). This

connection process must be performed

by a qualified electrician.

The plug connector or isolator switch

should be easily accessible at all times.

Risk of electric shock.

If the washing machine is disconnec-

ted from the mains, protective meas-

ures must be taken to ensure that the

point of disconnection cannot acci-

dentally be switched on again.

Make sure the isolator is lockable or

the point of disconnection is mon-

itored at all times.

New connections, modifications to the

system, or servicing of the earthing

conductor, including determining the

correct fuse amperage, must be carried

out by a qualified electrician, as they

are familiar with the pertinent regula-

tions and the specific requirements of

the electric utility company.

If converting the washing machine to

an alternative voltage, observe the

instructions in the wiring diagram.

Conversion must be performed by

Miele Service or by an authorised

Miele dealer.

Summary of Contents for 51508264IRL

Page 92: ......

Page 93: ......

Page 94: ......

Page 96: ...M Nr 11 881 460 00 en GB PWM 508 Mop Star 80 ...