Remove the three screws securing the dual ring

wok burner. Remove the wok burner base plate.

Lift the ceramic tray from the hob.

Note

Each regulator shaft is equipped with a black

ring. This ring may cling to the rubber seal in the

ceramic tray. Check and remove the rings from

the rubber seals.

For future use

Save the orifices removed from the appliance

for future use. For converting this appliance

back to Natural gas, follow the instructions and

use the numbers in brackets (… ).

Igniter

The relationship between the igniter and the

main burners can't be changed. The relationship

in the case of LP gas and natural gas is identical.

The distance between the igniter and the high

speed burner and super high speed burner is

± 3.5 mm. For the two zone

high speed burner the

distance between the

igniter and the inner ring is

± 2.5 mm.

Conversion instructions

Caution

Before proceeding with the conversion, shut off

the gas supply to the appliance prior to

disconnecting the electrical power.

Disassembly

Shut off gas supply, disconnect the manifold

pipe, disconnect the electrical power. Remove

pan supports, burner heads and burner rings.

Remove control knobs.

In the event that the hob is built in, undo the

bracket clamps underneath the work surface.

Lift the hob on to the work surface.

Unscrew the venturis on the high-speed and

super high-speed burners using a 20 mm

wrench. Lift and remove the burner rings and

burner base plates. Disconnect the wires from

the ignition plugs. Keep the wire from dropping

into the undertray by inserting it in one of the

slots in the burner supports.

Remove the top five screws in the back of the

hob undertray.

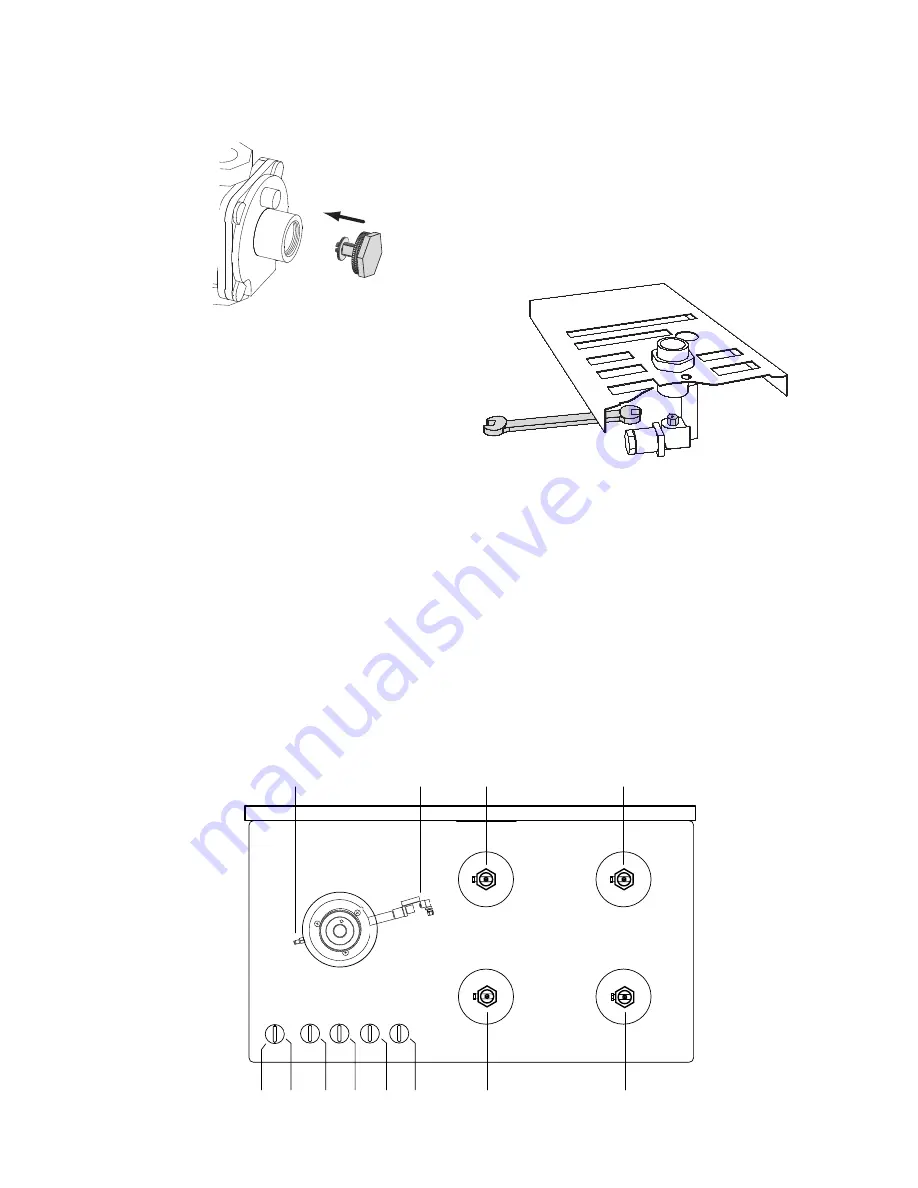

Pressure regulator conversion

The pressure regulator is located on the gas

supply pipe. Unscrew and remove the brass cap

in the centre of the regulator. This gas regulator

is only adjustable for 4" and 10" gas pressure.

There is a blue plastic pin on the inside of the

cap, marked "NAT" and "LP". Pull this pin from the

cap and insert it the other way round. Snap the

pin into the cap. The pin must be positioned as in

the drawing above. The regulator is now

adjusted for propane gas 10" WC. (For natural

gas 4", turn the pin back.) Screw the cap back on

the regulator. The pressure regulator is equipped

with a separate connection for pressure testing

purposes. Check gas pressure. Permitted

pressures: min. 11" WC (5" WC, natural gas), max.

1/2 psi.

High speed and super high speed burner

conversion

Unscrew and replace injectors on the high-

speed and super high-speed burners. Replace

each injector separately. Refer to illustration

“Locations of injectors and minimum adjustment

screws” for screw locations.

21

20

(034)

007

(170)

090

(166)

087

(145)

075

087

(166)

075

(145)

054

(100)

025

(042)

036

(055)

040

(060)

036

(055)

040

(060)

(Natural gas)

LP gas

LP gas

(Natural gas)

Locations of injectors and minimum adjustment screws