Installation

46

Installing the CombiSet

Feed the mains connection cable

down through the cut-out.

Starting at the front, position the

CombiSet in the worktop cut-out.

Using both hands, press down evenly

on the edges of the CombiSet until it

clicks into position. When doing this,

make sure that the seal underneath

the appliance sits flush with the

worktop. This is important to ensure

an effective seal with the worktop.

Do not use sealant (e.g. silicone).

If the seal does not meet the worktop

correctly on the corners, the corner

radii (

≤

R4) can be carefully scribed to

suit.

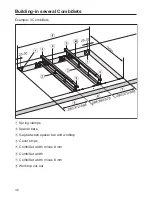

Installing several CombiSets

Push the built-in CombiSet to the

side until the holes in the spacer bar

can be seen.

Fit the cover strip

in the holes in

the spacer bar

.

Starting at the front, position the next

CombiSet in the worktop cut-out.

Proceed as described previously.