Installation

*

I

N

S

T

A

L

L

A

T

I

O

N

*

49

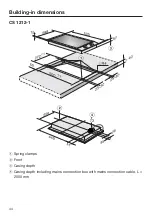

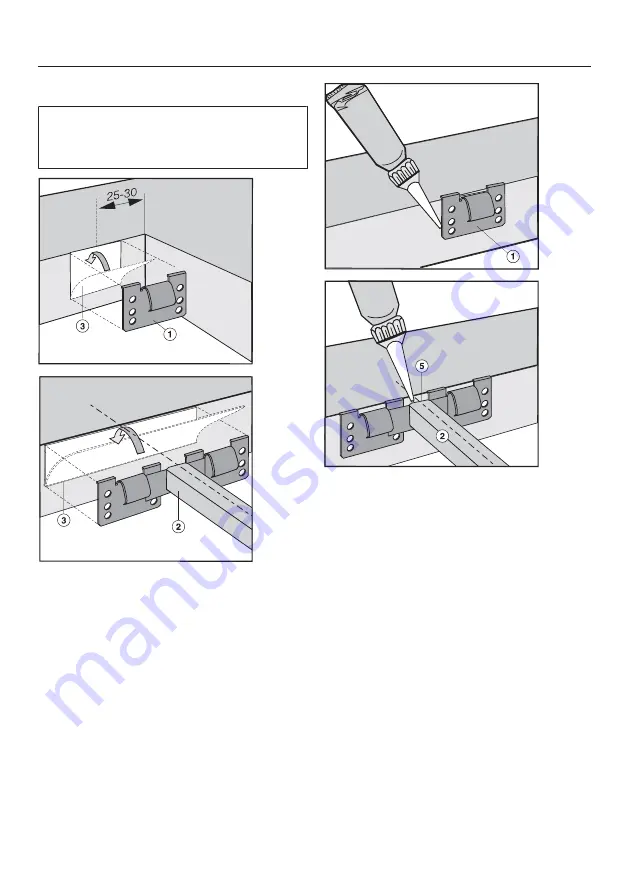

Natural stone worktops

You will need heavy duty double-sided

tape (not supplied) to secure the

spring clamps and spacer bars.

S

tick the tape

to the top edge of

the cut-out in the positions shown in

the diagram.

P

osition the spring clamps

and

spacer bars

on the top edge of the

cut-out and press them firmly into

place.

Apply silicone to the side and lower

edges of the spring clamps

and

the spacer bars

.

Then fill gap

between spacer

bar

and the worktop with silicone.