Grease filter timer

A timer monitors the hours of fan

operation. The indicator for the grease

filter will light after 30 hours of

operation. The grease filters must then

be cleaned.

After the grease filters have been

cleaned and put in place, the grease

filter timer must be reset.

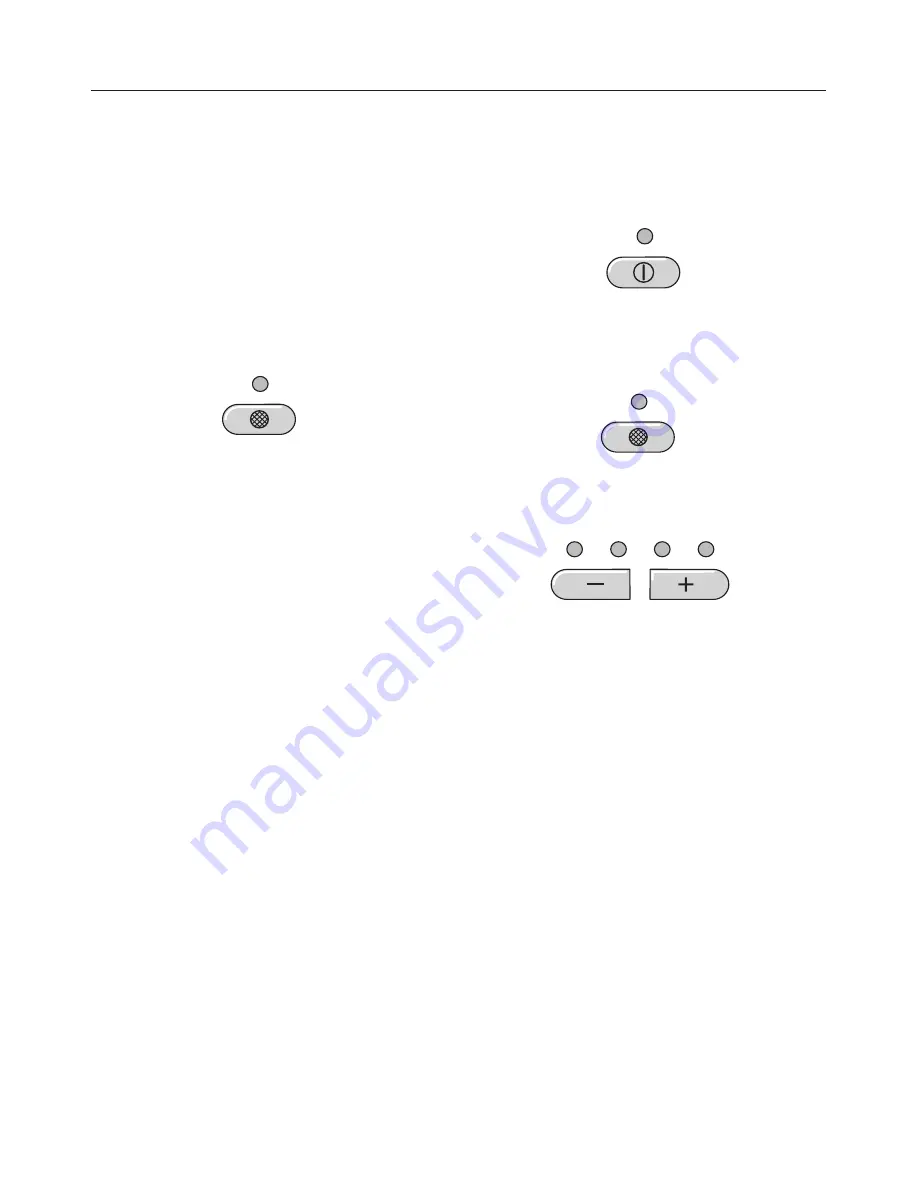

^

To do this, press the grease filter

button for about 3 seconds.

The indicator will go out.

Checking the grease filter timer

To check the percentage of time

already used:

^

Press the On/Off button to turn the

fan on.

^

Press the grease filter button.

The number of flashing

_

indicators

show the percentage of programmed

hours that have been used.

1 indicator = less than 25 %

2 indicators = less than 50 %

3 indicators = less than 75 %

4 indicators = less than 100 %

This information will remain stored in

memory in the event of a power failure.

Operation

12

Summary of Contents for DA 220-3

Page 8: ...Guide to the appliance 8 ...

Page 18: ...18 ...

Page 19: ...Installation Instructions ...

Page 32: ...M Nr 06 438 010 00 Alteration rights reserved 4304 ...