Summary of Contents for DA 239-3

Page 2: ...2 ...

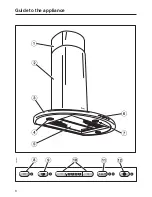

Page 8: ...Guide to the appliance 8 ...

Page 19: ...Installation Instructions ...

Page 20: ...20 ...

Page 22: ...Installation accessories 22 ...

Page 37: ...37 ...

Page 38: ...38 ...

Page 39: ...39 ...