Technical Information

29

DGC 6xxx

3.2 Noisy

Operation

Symptom:

Noisy operation.

Cause:

The convection fan impeller was incorrectly installed, which is causing it to

rotate unevenly and therefore grate against the inner rear panel.

Remedy:

1. A bushing is now in use, as well as a spacer on the fan axle. Refer to the

parts CD for current part numbers.

2. Install the new bushing and spacer. Refer to Steps 8 and 9 in Section

035-4.5 for disassembling the fan.

3.3

Rust on Top Heat/Broil Element

Symptom:

Rust on top heat/broil element.

Cause:

Heater element was made out of an unsuitable material.

Remedy:

Install a new top heat/broil element. See Section 030-4.2.

3.4

Convection Fan Too Loud

Symptom:

Convection fan is too loud. This noise is different than an audible imbalance

(grating sound) caused by the impeller.

Cause:

The impeller is screwed crookedly onto the fan axle.

Remedy:

Replace the impeller, since the opening for the axle feed-through has been

bent.

Refer to Steps 8 and 9 in Section 035-4.5 for disassembling the fan.

Note:

Fan replacement is not necessary, because the axle itself is not bent.

4

Service

4.1

Convection Element (R14) Removal

1. Remove the door; see Section 020-4.1.

2. Remove the appliance from its housing unit; see Section 010-4.1.

3. Disconnect the appliance from the power supply.

4. Remove the rear/left side panel; see Section 010-4.4.

5. Remove the two 7mm nuts securing the inner rear panel; take off the

Summary of Contents for DGC 6 Series

Page 1: ...TECHNICAL INFORMATION DGC 6xxx Combi Steam Ovens 2018 Miele USA ...

Page 15: ...Technical Information 15 DGC 6xxx 010 Casing ...

Page 23: ...Technical Information 23 DGC 6xxx 020 Door ...

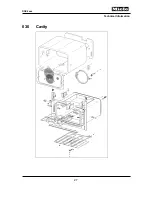

Page 27: ...Technical Information 27 DGC 6xxx 030 Cavity ...

Page 43: ...Technical Information 43 DGC 6xxx 035 Steam Generator Convection Fan ...

Page 57: ...Technical Information 57 DGC 6xxx Figure 035 14 Terminal Block ...

Page 58: ...Technical Information 58 DGC 6xxx 040 Water Container Drive ...

Page 68: ...Technical Information 68 DGC 6xxx 045 Air Duct Power Electronic ...