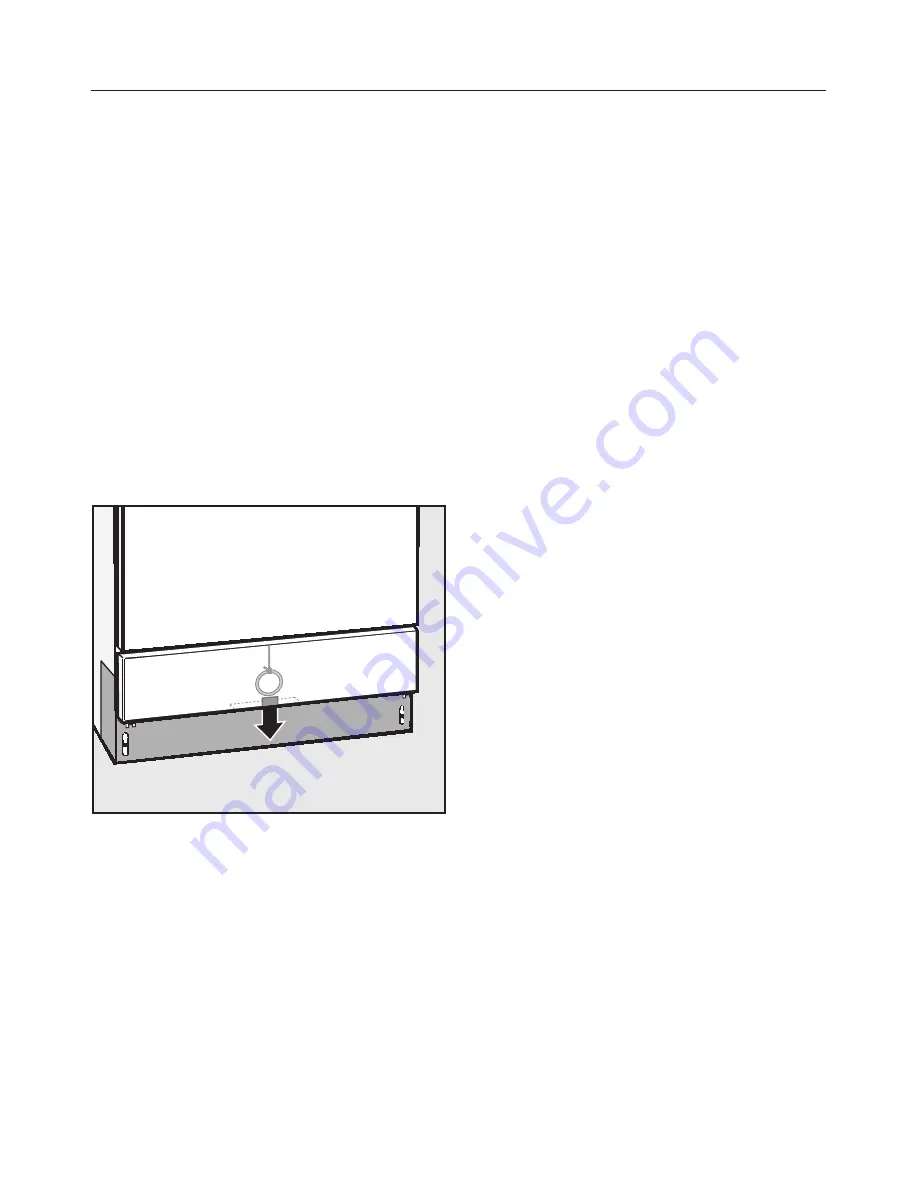

To open the door with the

emergency release

The emergency release should only be

used when the door cannot be opened

normally, e.g. in the event of a power

failure.

Important

It is essential to follow procedures, par-

ticularly with regard to regulations on

preventing the spread of epidemics, as

described in "Operation - cancelling a

programme".

^

Turn the programme selector to

f

.

^

Press

I-0

to switch the machine off.

^

The emergency release cable is lo-

cated at the bottom of the machine

behind the service panel. Pull it

downwards to open the door.

Opening and closing the door

14

Summary of Contents for G 7882

Page 3: ...Installation 53 Electrical connection 55 Plumbing 57 Technical data 60 Contents 3 ...

Page 65: ...61 ...

Page 66: ...62 ...

Page 67: ...63 ...